This is an old revision of the document!

AN009 - EtherCAT configuration nr.01

The purpose of this application note is to illustrate a simple guide for using RosettaCNC board B with EtherCAT command.

1. What is the configuration nr.01

The configuration nr.01 consists of a series of Delta ServoDrives model ASD-A2-0421-E. Up to 7 ServoDrives can be connected. Spindle is driven by analogic output. No EtherCAT Spindle device is provided for this configuration.

2. Necessary material

We need:

- A RosettaCNC board B purchased with EtherCAT option (see “Order Code” “Motor control type” at value E).

- From 1 to 7 ServoDrives purchased from RosettaCNC team (preconfigured to be ready to go)

3. Preliminary operations

- Install the latest version of the RosettaCNC software

- Download the attached sfs file and copy it to %appdata%\RosettaCNC-1\firmware.

- Open the “Board firmware manager” panel and start to download the EtherCAT firmware named RosettaCNC-BE-01.

- Open Board settings panel, press Import.. buttom and load the attached XML file.

At the end connect RosettaCNC software to the board. The software, only at the first run, takes some time (3-4 minutes) to generate a cache and be fast in subsequent runs. You can see the progress in the progress bar at the bottom in the RosettaCNC software.

4. Addressing

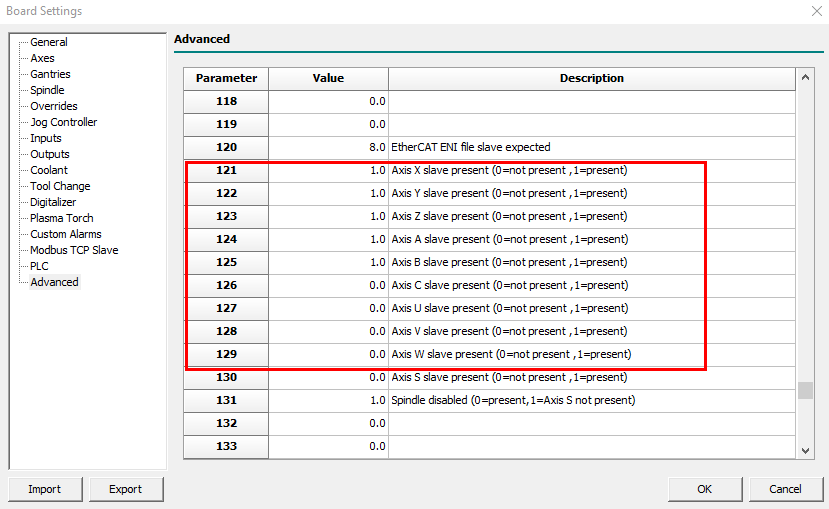

This configuration uses the Auto Increment Address of the EtherCAT slave device. Auto-increment addressing can be used to address each slave device is via its physical position in the communication ring. The first slave in the ring is X-axis, the second Y-axis, etc. This is the slave list:

- X-Axis

- Y-Axis

- Z-Axis

- A-Axis

- B-Axis

- C-Axis

- V-Axis

If the machine miss an Axis the physical cable must follow the next axis present.

5. Update EtherCAT ring configuration

6. Attached files

7. ServoDrive settings

Same servo drive settings are available on Advanced parameters. Other must be set by Delta configuration software.

8. Note

- Depending on the machine requirements, the STO safety signals must be wired correctly.

The proposed configuration is for demonstration purposes only.

- To reverse the motor rotation, change parameter P1-01 from 0x000c to 0x010c, and the parameter P3-12 from 0x0000 to 0x0100