RosettaCNC Board B - Installation and Maintenance manual

Dear Customer,

Thank you for purchasing this product. RosettaCNC Board B is developed and manufactured with high standards to give high quality performance, ease of use and installation.

In case of difficulty during installation or use of the product, We recommend that you first consult the instructions or information on the www.rosettacnc.com site.

Need help?

Write in the forum on the www.rosettacnc.com site or send an email to the following address: support@rosettacnc.com, the RosettaCNC development team will be happy to answer you in a short time.

All rights reserved on this manual. No part of this document can be copied or reproduced in any form without prior written authorisation. RosettaCNC Motion® does not insure or guarantee its contents and explicitly declines all liability related to the guarantee of its suitability for any purpose. The information in this document can be changed without notice. RosettaCNC Motion® shall not be held liable for any error or omission in this document. RosettaCNC Motion® is a registered trademark.

Informations

|

||||

| Document: | MIMROSETTACNCBOARDB | |||

|---|---|---|---|---|

| Description: | Installation and Maintenance manual | |||

| Link: | https://wiki.rosettacnc.com/doku.php/en:hardware:rosettacncboard:mimrosettacncboardb | |||

| Document release | Hardware Release | Description | Note | Data |

| 1 | 01.0 | New manual | / | 21/12/2018 |

| 2 | 01.0 | Corrected of description connectors CN8-9 because reversed and CN20-25 for the same reason. | / | 18/02/2019 |

| 3 | 01.0 | New order code | / | 03/05/2019 |

| 4 | 01.0 | New CN11 description for RosettaCNC software version 1.6 | / | 31/07/2019 |

| 5 | 01.0 | Update order code, add Laser connection, Fix translation | / | 02/09/2019 |

| 6 | 01.0 | Add new commercial version | / | 21/11/2019 |

| 7 | 01.0 | Add new order code with “Jerk control” feature | / | 05/06/2020 |

| 8 | 01.0 | New Motor control Type “A” (position closed loop). New expansion option. | / | 31/03/2021 |

| 9 | 03.0 | Add options 2 and 3 in the I/O Expansion | / | 18/02/2025 |

1. Introduction

1.1 General description

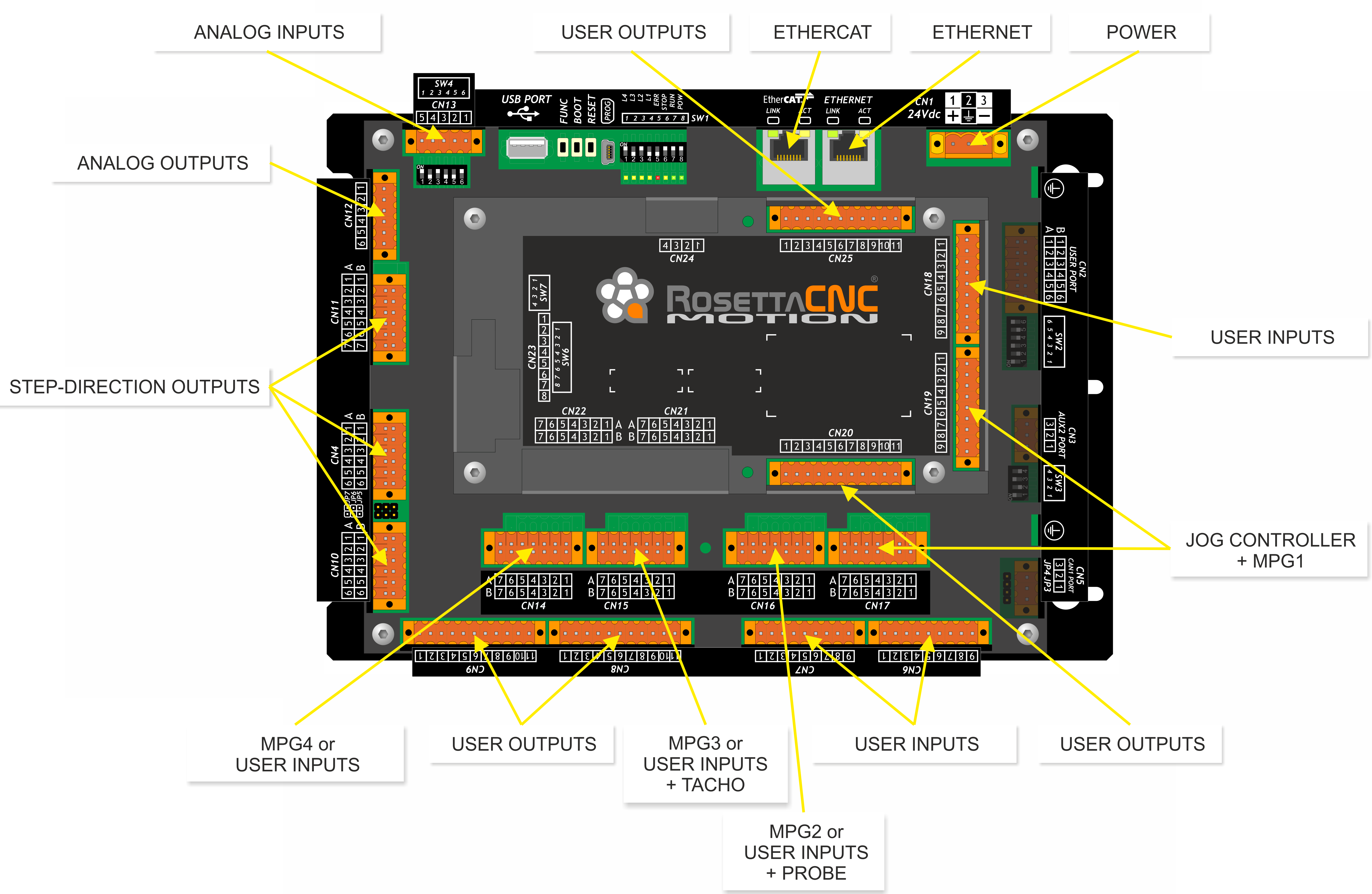

RosettaCNC Board B is an ETHERNET motion controller that manages up to 6 interpolated axes. The ETHERNET port (instead of USB) ensures fast and secure transmission thanks to the protocol and at the e galvanic insulation with the PC connection.

Does not require the use of external electronic parts or protectors. The power supply is integrated and protected, The inputs and outputs are equipped with opto-insulation that guarantee, together with the metal container, high resistance to electromagnetic interference. The outputs are protected from short circuits and allow you to directly connect inductive loads (relays or solenoid valves), without having to add external components.

The control outputs of STEP/DIR type are generated by a powerful FPGA That allows to reach operating frequencies of 1MHz making it possible to use both step-by-step drives and servo drives.

Rosetta CNC Board commands the axes using a look ahead that allows you to achieve high interpolation speeds.

The product can possibly be equipped with a handwheel, supplied already complete with connector, alternatively, it makes available inputs for the jog connection joystick type and other useful control signals.

Rosetta CNC Board is equipped with removable spring connectors to allow quick wiring, highly reliable and free to vibrations.

1.2 Symbols used in the manual

Useful Information and tips

Warnings, failure to comply with these warnings may result in inappropriate operation or damage to the device

Potential danger and possible risk of injury

1.3 System composition

RosettaCNC Motion® is a system composed of the following elements:

- RosettaCNC Board B which is the motion controller described in this document.

- RosettaCNC software, a complete Windows® application to configure, monitor, and execute G codes.

- The RosettaCNC Handwheel A accessory, a practical and economical handwheel.

- The RosettaCNC MPG A accessory, is a rotary device to change the override.

1.4 Product Compliance

CE Marking and reference standards

The controller has been designed for industral environments in conformity to EC directive 2004/108/CE.

- EN 61000-6-4: Electromagnetic compatibility - Generic standard on emission for industrial environments

- EN55011 Class A: Limits and measurement methods

- EN 61000-6-2: Electromagnetic compatibility - Generic standard on immunity for industrial environments

- EN 61000-4-3: Immunity to radiated, radio-frequency electromagnetic field

- EN 61000-4-4: Electrical fast transients

- EN 61000-4-5: Surge immunity

- EN 61000-4-6: Conducted disturbance induced by radio-frequency

- Moreover the product is conform to the following standards:

- EN 60068-2-1: Environmental testing: Cold

- EN 60068-2-2: Environmental testing: Dry heat

1.5 Package Contents

- n.1 RosettaCNC Board B

- n.1 Spring terminals kit

N.B.: The female connectors for CN2, CN3 and CN5 are not provided

1.6 Product identification

With the product ordering code it's possible to obtain exactly the features.

Check that the product features match your needs.

1.6.1 Product label

- a - Ordering Code

- b - Week made: indicates the week and year of manufacture

- c - Part number: unique code that identifies an ordering code

- d - Serial number: product serial number, different for individual product

- e - Hardware release: version of hardware release

1.6.2 Ordering code

| Model | - | Features | |||||||||||||

| RosettaCNC B | - | 6 | / | 0 | / | 0 | / | 1 | / | 1 | / | 1 | - | 001 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Customization Code. (omitted if no customization is present) | |||||||||||||||

| Functions “Group B”. 0 = No functions enabled; 1 = Laser Acquisition; 2 = internal THC; 4 = Tilting head AB; 6 = internal THC and tilting head AB; | |||||||||||||||

| Functions “Group A”. 0 = No Functions Enabled; 1 = RTCP; 2 = Jerk control; 3 = RTCP + Jerk control; | |||||||||||||||

| Remote communication. 0 = No communication; 1 = OPC; 2 = OPC + RosettaCNC Data Exchange 4.0; | |||||||||||||||

| I/O Expansion. 0 = Not present; 1 = CN21-CN22-CN24; 2 = RS485 & CANbus; 3 = Option 1 + Option 2 | |||||||||||||||

| Motor control type. 0 = 125 KHz; 1 = 200Khz; 2 = 300Khz; 3 = 500Khz; 4 = 1Mhz; 5 = 2Mhz; A = Position control loop ; E = EtherCAT | |||||||||||||||

| Axis number. 3 = 3 axis; 4 = 4 axis; 5 = 5 axis; 6 = 6 axis; | |||||||||||||||

| Controller model. RosettaCNC B = Controller Board B | |||||||||||||||

1.6.3 Codes normally available

| Part number | Model | Features |

|---|---|---|

| 97500008 | RosettaCNC B - 6/4/0/0/0/0 | 6 axes, max step freq 1 MHz |

| 97500021 | RosettaCNC B - 6/4/0/0/0/1 | 6 assi, max step freq 1 MHz, Laser Aquisition |

| 97500013 | RosettaCNC B - 6/4/0/1/0/0 | 6 axes, max step freq 1 MHz, OPC-UA server |

| 97500014 | RosettaCNC B - 6/4/0/0/1/0 | 6 axes, max step freq 1 MHz, RTCP |

| 97500015 | RosettaCNC B - 6/4/0/1/1/1 | 6 axes, max step freq 1 MHz, OPC-UA server, RTCP |

1.7 Specification

| Description | Value |

|---|---|

| Power supply | 24VDC |

| Maximum absorption | 12W |

| Axis number | 6 |

| Digital inputs | 32 |

| Handwheel interface | 6-Axis Selector x1-x10-x100 Selector |

| EXTRA digital inputs | 10 1) |

| Analog inputs | 3 |

| Digital outputs | 32 |

| Analog outputs | 1 |

| Axis control type | STEP/DIR |

| PC Communication | Ethernet 10/100Mb |

| Temperature range | 0°C to +50°C |

| MPG inputs | 3 + 12) |

| Enclosure Protection Degree | IP20 (as from EN-60529 normative) |

2. Safety

RosettaCNC Board it's powered in low voltage, 24VDC, the I/O line are opto-insulation and the PC connection is galvanically isolated, therefore the device is not a direct threat to the health and life of the user.

The design of a complete control system (electric panel), should draw attention to different aspects of, so that the whole machine system does not become a danger during the use.

It's good practice to always use NC contacts for the limit switches and for the emergency button So that a wiring error or a wire disconnection always lead to machine shutdown.

Special attention must be paid to the emergency stop circuit: The control system must be designed in such a way the that when you press the button for emergency stop, the machine immediately interrupts the movement of all axes. You should also consider the possibility of failure of particular components of the system, as the main controller, or the axes control units.

The safety of the machine is never the responsibility of the RosettaCNC Board Controller

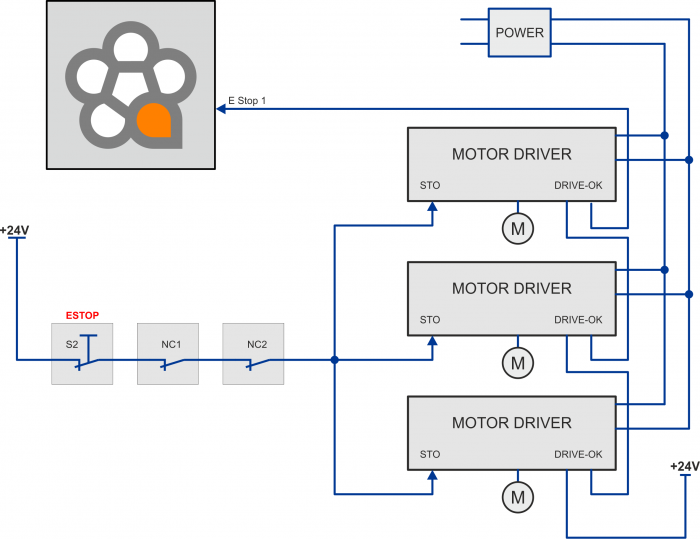

Here are two examples of connection. The first uses the Safe Torque Off (STO) input Present in drives.

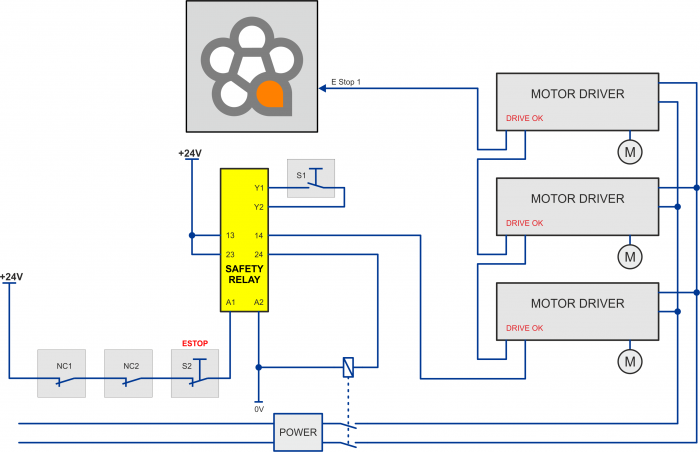

The second uses a safety device to control the chain of emergency signals.

Both are only example schemes and each installer must then design its own scheme suitable for the machine according to the regulations.

In the below picture, is used a safety device Pilz model PNOZ X7. The emergency button, and possibly other alarm signals (safety barriers, crankcase opening, etc.) must be connected to the input circuits. An output must be connected to the EST1 input of RosettaCNC Board And in series also the drive ok outputs. The other exit of the safety module must be used to stop power to drives.

S1 is the Restore button.

S2 is the stop button in emergency.

3. Mechanical Installation

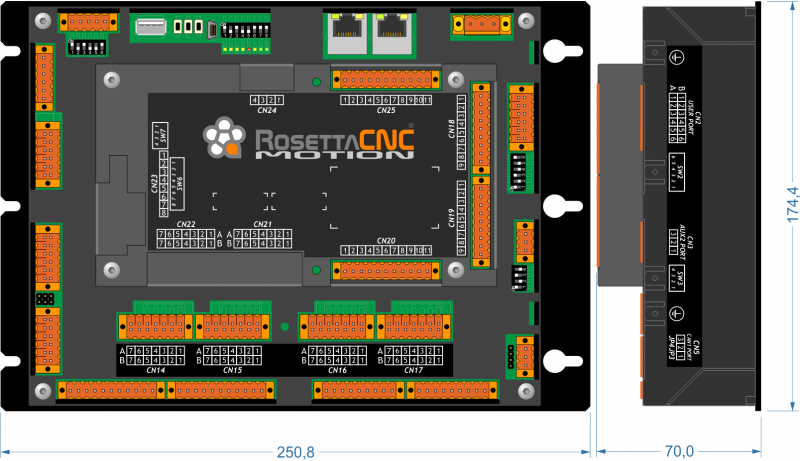

3.1 Mechanical dimensions

Dimensions in mm

3.2 Hole template

4. Connectors

For information about the usable cable sections and the used connectors, see the Application Note AN001

4.1 Expansion I/O = 0

4.2 Expansion I/O = 1

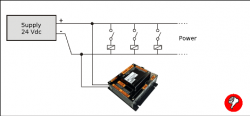

4.3 Power supply

The wiring must be carried out by specialized personnel and provided with appropriate anti-static measures.

Before handling the instrument, remove voltage and all parts connected to it.

To ensure with the CE compliance, The supply voltage must have a galvanic insulation of at least 1500 Vac.

| Available power supplies | 24 Vdc |

|---|---|

| Valid range | 22 ÷ 27 Vdc |

| Max. absorption | 10W |

Connector

| CN1 | Terminal | Symbol | Description | |

|---|---|---|---|---|

|  | 1 | | Positive power supply |

| 2 | GROUND | Ground-PE (signals) | ||

| 3 | | 0V power supply | ||

Connection examples

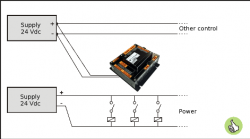

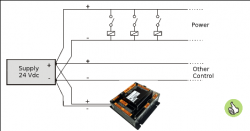

Is prescribed the use of insulated power supply with 24Vdc output complies with EN60950-1.

| Use two separate power supplies: one for the control part and one for the power part |

| In the case of a single power supply, Use two separate lines: one for control and one for power |

| Do not use the same lines as the power part |

4.4 Serial Connections

4.4.1 ETHERNET port

| ETHERNET PORT | Description |

|---|---|

| RJ45 connector. LED: * LINK: green led = connected cable (the LED on indicates that the cable is connected to both sides) * DATA: yello led = data exchange (the blinking LED indicates the data exchange between the connected devices) |

4.5 Digital inputs

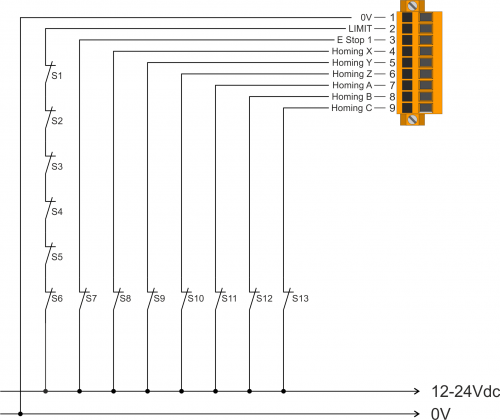

The digital inputs called “User input” can be configured by the RosettaCNC software to perform some functions. For example; ESTOP 1, Spindle ok speed, Spindle zero speed, Limit, Start, Safety barriers, etc.

4.5.1 CN7

| CN7 | Terminal | User inputs | Homing inputs | ||

|---|---|---|---|---|---|

| Symbol | Description | Symbolo | Description | ||

| 1 | 0V | Common of digital Inputs | ||

| 2 | I1 | User input I1 | |||

| 3 | I2 | User input I2 | |||

| 4 | I3 | User input I3 | HMX | Homing X | |

| 5 | I4 | User input I4 | HMY | Homing Y | |

| 6 | I5 | User input I5 | HMZ | Homing Z | |

| 7 | I6 | User input I6 | HMA | Homing A | |

| 8 | I7 | User input I7 | HMB | Homing B | |

| 9 | I8 | User input I8 | HMC | Homing C | |

4.5.2 CN6

| CN6 | Terminal | User inputs | |

|---|---|---|---|

| Symbol | Description | ||

| 1 | 0V | Common of digital Inputs |

| 2 | I9 | User input I9 | |

| 3 | I10 | User input I10 | |

| 4 | I11 | User input I11 | |

| 5 | I12 | User input I12 | |

| 6 | I13 | User input I13 | |

| 7 | I14 | User input I14 | |

| 8 | I15 | User input I15 | |

| 9 | I16 | User input I16 | |

4.5.3 CN18

| CN18 | Terminal | User inputs | |

|---|---|---|---|

| Symbol | Description | ||

| 1 | 0V | Common of digital Inputs |

| 2 | I17 | User input I17 | |

| 3 | I18 | User input I18 | |

| 4 | I19 | User input I19 | |

| 5 | I20 | User input I20 | |

| 6 | I21 | User input I21 | |

| 7 | I22 | User input I22 | |

| 8 | I23 | User input I23 | |

| 9 | I24 | User input I24 | |

4.5.4 Electrical features

| Type | PNP |

| Minimum acquisition time (hardware) | 3ms |

| Rated operating voltage | 12÷24Vdc |

| Maximum voltage | 26.5Vdc |

| Voltage state logic 0 | < 2 V |

| Voltage state logic 1 | > 10.5 V |

| Absorbed current | 2mA@10.5V / 8mA@26.5V |

4.5.5 Connection examples

| S1 | Limit X |

| S2 | Limit Y |

| S3 | Limit Z |

| S4 | Limit A |

| S5 | Limit B |

| S6 | Limit C |

| S7 | E Stop 1 |

| S8 | Home X |

| S9 | Home Y |

| S10 | Home Z |

| S11 | Home A |

| S12 | Home B |

| S13 | Home C |

4.5.6 CN19 and CN17

The following connectors are used for different functionalities depending on the value of the “Controller type” parameter. This parameter is present in the “RosettaCNC card settings” panel → Jog. Furthermore, the digital inputs named MPG can be configured through the RosettaCNC software to manage override. The settings are found in the “RosettaCNC Tab Settings” → “Overrides” panel. The following override can be managed:

- Jog Speed

- Fast Speed (G0)

- Feed Speed (G1,G2,ecc)

- Spindle Speed

| CN19 | Terminal | “Jog Controller Type” parameter | Ingressi utente | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HandWheel A | Single Joystick | Multiple Joystick | ||||||||||

| Symbol | Description | Symbol | Description | Symbol | Description | Simbolo | Descrizione | |||||

| 1 | 0V | Common of digital inputs | 0V | Common of digital inputs | 0V | Common of digital inputs | 0V | Comune degli ingressi digitali | |||

| 2 | HSX | Handwheel Sel.Axis X | CSX | Controller Sel.Axis X | JXP | Jog X+ | I33 | User input I33 | ||||

| 3 | HSY | Handwheel Sel.Axis Y | CSY | Controller Sel.Axis Y | JXM | Jog X- | I34 | User input I34 | ||||

| 4 | HSZ | Handwheel Sel.Axis Z | CSZ | Controller Sel.Axis Z | JYP | Jog Y+ | I35 | User input I35 | ||||

| 5 | HSA | Handwheel Sel.Axis A | CSA | Controller Sel.Axis A | JYM | Jog Y- | I36 | User input I36 | ||||

| 6 | HMO | Handwheel Multiplier x1 | ZERO | Zero | JZP | Jog Z+ | I37 | User input I37 | ||||

| 7 | HMT | Handwheel Multiplier x10 | JP | Jog + | JZM | Jog Z- | I38 | User input I38 | ||||

| 8 | HMH | Handwheel Multiplier x100 | JM | Jog - | JAP | Jog A+ | I39 | User input I39 | ||||

| 9 | HSB | Handwheel Sel.Axis B | CSB | Controller Sel.Axis B | JAM | Jog A- | I40 | User input I40 | ||||

| . | ||||||||||||

| CN17 | Terminal | “Jog Controller Type” parameter | ||||||||||

| HandWheel A | Single Joystick | Multiple Joystick | MPG 1 / User inputs | |||||||||

| Symbol | Description | Symbol | Description | Symbol | Description | Symbol | Description | |||||

| 1A | 5V | 5 Volts DC output | 5V | 5 Volts DC output | 5V | 5 Volts DC output | 5V | 5 Volts DC output | |||

| 2A | - | I41 | User input I41 | |||||||||

| 3A | - | I42 | User input I42 | |||||||||

| 4A | HSC | Handwheel Sel.Axis C | CSC | Controller Sel.Axis C | I43 | User input I43 | ||||||

| 5A | 0V | To Connect with 5B | To Connect with 5B | To Connect with 5B | To Connect with 6A | |||||||

| 6A | To Connect with 6B | To Connect with 6B | To Connect with 6B | To Connect with 6B | ||||||||

| 7A | To Connect with 7B | To Connect with 7B | To Connect with 7B | To Connect with 7B | ||||||||

| 1B | ||||||||||||

| 2B | HPA | Handwheel Controller PHA - [ MPG 1 ] | CPA | Controller PHA - [ MPG 1 ] | CPA | Controller PHA - [ MPG 1 ] | CPA | Controller PHA - [ MPG 1 ] | ||||

| 3B | HPB | Handwheel Controller PHB - [ MPG 1 ] | CPB | Controller PHB - [ MPG 1 ] | CPB | Controller PHB - [ MPG 1 ] | CPB | Controller PHB - [ MPG 1 ] | ||||

| 4B | ||||||||||||

| 5B | To Connect with 5A | To Connect with 5A | To Connect with 5A | To Connect with 5A | ||||||||

| 6B | To Connect with 6A | To Connect with 6A | To Connect with 6A | To Connect with 6A | ||||||||

| 7B | To Connect with 7A | To Connect with 7A | To Connect with 7A | To Connect with 7A | ||||||||

4.5.6.1 Electrical features

Inputs of CN19

| Type | PNP |

| Minimum acquisition time (hardware) | 3ms |

| Rated operating voltage | 12÷24Vdc |

| Maximum voltage | 26.5Vdc |

| Voltage state logic 0 | < 2 V |

| Voltage state logic 1 | > 10.5 V |

| Absorbed current | 2mA@10.5V / 8mA@26.5V |

Inputs of CN17

| Type | PNP(12-24V) | PNP(5V) |

| Terminal | 2A, 3A, 4A | 2B, 3B, 4B |

| Maximum frequency | 200KHz | |

| Minimum acquisition time | 5µs | |

| Insulated | 1000Vrms | |

| Nominal operating voltage | 24Vdc | 5Vdc |

| Voltage State Logic 0 | 0 ÷ 2 V | 0÷1,5 V |

| Voltage State Logic 1 | 10,5 ÷ 26,5 V | 2÷5 V |

| Internal Voltage Drop | 1,2V | |

| Input resistance | 3100Ω | 150Ω |

4.5.6.2 Connection examples

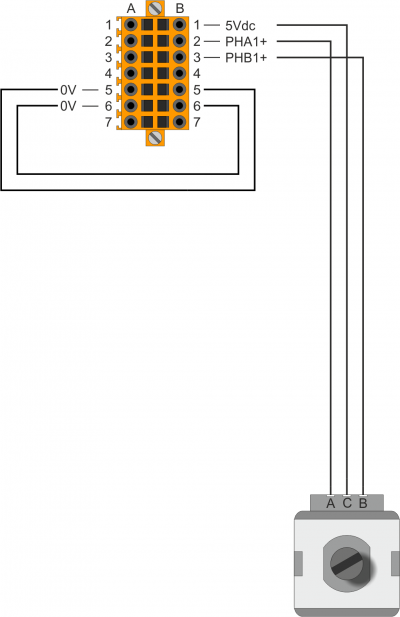

For the connection of the Handwheel refer to the Handwheel A documentation

4.5.7 CN14

It Can be used as MPG4 or as “User Inputs”.

| CN14 | Terminal | User inputs | MPG4 | ||||

|---|---|---|---|---|---|---|---|

| Symbol | Description | Symbol | Description | ||||

| 1A | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | ||

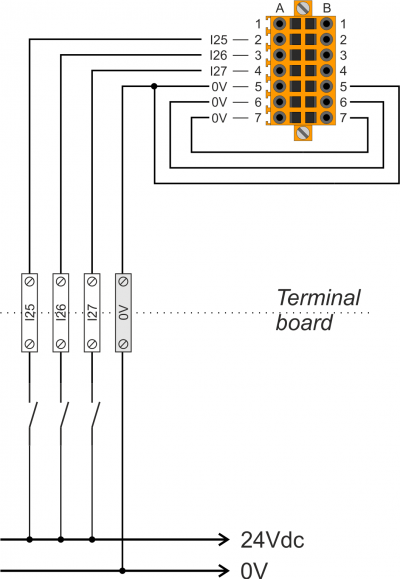

| 2A | I25 | I25 User Input | |||||

| 3A | I26 | I26 User Input | |||||

| 4A | I27 | I27 User Input | |||||

| 5A | Connected with 5B | Connected with 5B | |||||

| 6A | Connected with 6B | Connected with 6B | |||||

| 7A | Connected with 7B | ||||||

| 1B | |||||||

| 2B | PHA | A Phase | |||||

| 3B | PHB | B Phase | |||||

| 4B | |||||||

| 5B | Connected with 5A | Connected with 5A | |||||

| 6B | Connected with 6A | Connected with 6A | |||||

| 7B | Connected with 7A | ||||||

4.5.8 CN15

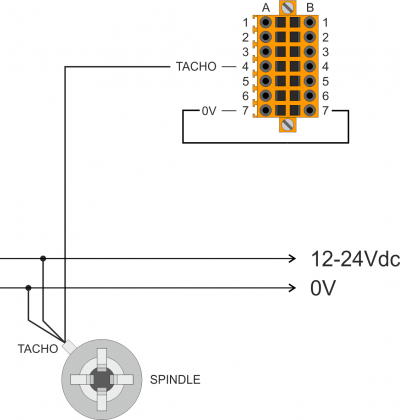

It Can be used as MPG3 or as “User Inputs”. It's also possible to connect the spindle tachometer signal.

| CN15 | Terminal | User Inputs | MPG3 | TACHO | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Symbol | Description | Symbol | Description | Symbol | Description | |||||

| 1A | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | |||

| 2A | I28 | I28 User Input | ||||||||

| 3A | I29 | I29 User Input | ||||||||

| 4A | I30 | I30 User Input | TACHO | TACHO Sensor | ||||||

| 5A | Connected with 5B | Connected with 5B | ||||||||

| 6A | Connected with 6B | Connected with 6B | ||||||||

| 7A | Connected with 7B | Connected with 7B | ||||||||

| 1B | ||||||||||

| 2B | PHA | A Phase | ||||||||

| 3B | PHB | B Phase | ||||||||

| 4B | ||||||||||

| 5B | Connected with 5A | Connected with 5A | ||||||||

| 6B | Connected with 6A | Connected with 6A | ||||||||

| 7B | Connected with 7A | Connected with 7A | ||||||||

4.5.9 CN16

It can be used as MPG2 or as “User Inputs”. It's also allowed to connect the PROBE.

| CN16 | Terminal | User inputs | MPG2 | PROBE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Symbol | Description | Symbol | Description | Symbol | Description | |||||

| 1A | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | |||

| 2A | I31 | I31 User Input | ||||||||

| 3A | I32 | I32 User input | ||||||||

| 4A | I50 | I50 User input | PROBE | PROBE Sensor | ||||||

| 5A | Connected with 5B | Connected with 5B | ||||||||

| 6A | Connected with 6B | Connected with 6B | ||||||||

| 7A | Connected with 7B | Connected with 7B | ||||||||

| 1B | ||||||||||

| 2B | PHA | A Phase | ||||||||

| 3B | PHB | B Phase | ||||||||

| 4B | ||||||||||

| 5B | Connected with 5A | Connected with 5A | ||||||||

| 6B | Connected with 6A | Connected with 6A | ||||||||

| 7B | Connected with 7A | Connected with 7A | ||||||||

4.5.10 CN22

Può essere usato come “Ingresso encoder Asse A”.

| CN22 | Terminal | User inputs | MPG6 | ||||

|---|---|---|---|---|---|---|---|

| Symbol | Description | Symbol | Description | ||||

| 1A | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | ||

| 2A | I47 | I47 User Input | |||||

| 3A | I48 | I48 User input | |||||

| 4A | I49 | I49 User input | |||||

| 5A | Connected with 5B | Connected with 5B | |||||

| 6A | Connected with 6B | Connected with 6B | |||||

| 7A | Connected with 7B | ||||||

| 1B | |||||||

| 2B | PHA | A Phase | |||||

| 3B | PHB | B Phase | |||||

| 4B | |||||||

| 5B | Connected with 5A | Connected with 5A | |||||

| 6B | Connected with 6A | Connected with 6A | |||||

| 7B | Connected with 7A | ||||||

CN22 connector available only with field I/O Expansion = 1, in order code.

4.5.11 CN21

Può essere usato come “Ingresso encoder Asse B”.

| CN21 | Terminal | User inputs | MPG5 | ||||

|---|---|---|---|---|---|---|---|

| Symbol | Description | Symbol | Description | ||||

| 1A | 5Vdc | +5Vdc Output | 5Vdc | +5Vdc Output | ||

| 2A | I44 | I44 User Input | |||||

| 3A | I45 | I45 User input | |||||

| 4A | I46 | I46 User input | |||||

| 5A | Connected with 5B | Connected with 5B | |||||

| 6A | Connected with 6B | Connected with 6B | |||||

| 7A | Connected with 7B | ||||||

| 1B | |||||||

| 2B | PHA | A Phase | |||||

| 3B | PHB | B Phase | |||||

| 4B | |||||||

| 5B | Connected with 5A | Connected with 5A | |||||

| 6B | Connected with 6A | Connected with 6A | |||||

| 7B | Connected with 7A | ||||||

CN21 connector available only with field I/O Expansion = 1, in order code.

4.5.11.1 Electrical features

| Type | PNP(12-24V) | PNP(5V) |

| Terminal | 2A, 3A, 4A | 2B, 3B, 4B |

| Maximum frequency | 200KHz | |

| Minimum acquisition time | 5µs | |

| Insulated | 1000Vrms | |

| Nominal operating voltage | 24Vdc | 5Vdc |

| Voltage State Logic 0 | 0 ÷ 2 V | 0÷1,5 V |

| Voltage State Logic 1 | 10,5 ÷ 26,5 V | 2÷5 V |

| Internal Voltage Drop | 1,2V | |

| Input resistance | 3100Ω | 150Ω |

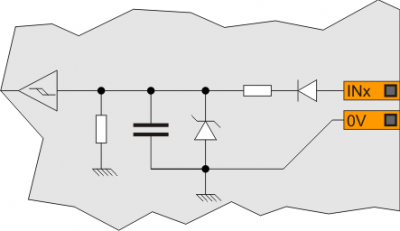

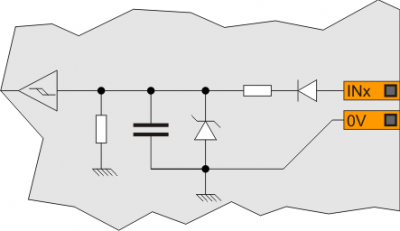

4.5.11.2 Connection examples

MPG to 5V dc

12-24V dc User inputs

PROBE 12-24V dc Input

TACHO 12-24V dc Input

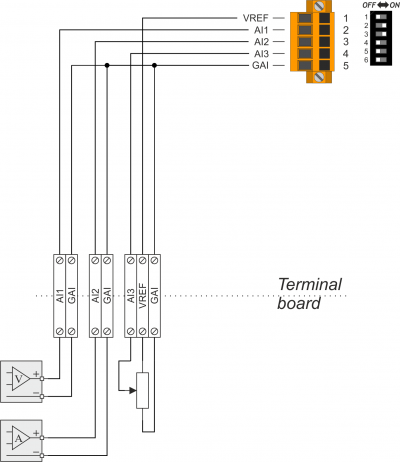

4.6 Analog inputs

Each analogue input can be configured via the RosettaCNC software to manage an override. The settings are found in the “RosettaCNC tab Settings ” Panel → “Overrides”.

The following parameters can be set:

- Jog Speed

- Fast (G0) Speed

- Feed (G1,G2,ecc) Speed

- Spindle Speed

4.6.1 CN13

| CN13 | Terminal | Symbol | Description | Address |

|---|---|---|---|---|

| 1 | VREF | Reference Voltage 1) | |

| 2 | AI1 | Analog input 1 | 2.AI01 | |

| 3 | AI2 | Analog input 2 | 2.AI01 | |

| 4 | AI3 | Analog input 3 | 2.AI03 | |

| 5 | GAI | Common of Analogue Inputs |

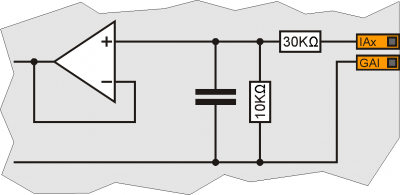

4.6.2 Analog Inputs settings

| SW4 | Num. Dip | Analog input 1 | Analog input 2 | Analog input 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pot. | 0-10V | 0-20mA | Pot. | 0-10V | 0-20mA | Pot. | 0-10V | 0-20mA | ||

| 1 | OFF | OFF | ON | X | X | X | X | X | X |

| 2 | OFF | ON | OFF | X | X | X | X | X | X | |

| 3 | X | X | X | OFF | OFF | ON | X | X | X | |

| 4 | X | X | X | OFF | ON | OFF | X | X | X | |

| 5 | X | X | X | X | X | X | OFF | OFF | ON | |

| 6 | X | X | X | X | X | X | OFF | ON | OFF | |

X = Irrelevant setting

Pot. = Potentiometer input type

0-10V = Voltmetric type input

0-20mA = Amperometric type input

4.6.3 Electrical features

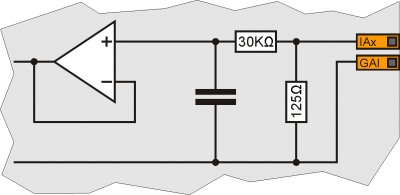

4.6.3.1 Analog Input with Amperometric configuration 0-20mA

| Connection type | Amperometric (0-20 mA) |

| Resolution | 12bit |

| Input resistance | 125Ω |

| Value of damage | 25 mA |

| Max. Linearity error | + 0,1% Vfs |

| Max. Offset error | + 0,1% Vfs |

| S.n. | 71 dB |

| Conversion time | It depends on the configuration of the analog input. See section Conversion times if present 1) |

| Isolation | 1000 Vrms |

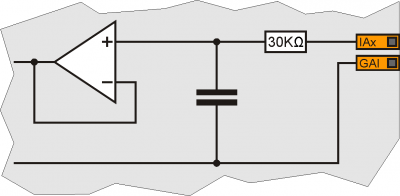

4.6.3.2 Analog input in potentiometric configuration

| Connection type | Potentiometric 1KΩ÷20KΩ |

| Resolution | 12bit |

| Reference voltage output | 2,5Vdc |

| Max output current from reference | 10mA |

| Input resistance | 10MΩ |

| Max. Linearity error | + 0,1% Vfs |

| Max. Offset error | + 0,1% Vfs |

| S.n. | 71 dB |

| Conversion time | It depends on the configuration of the analog input. See section Conversion times if present 1) |

| Isolation | 1000 Vrms |

4.6.3.3 Analog input in voltmetric configuration

| Connection type | Voltmetrico 0÷10V |

| Resolution | 12bit |

| Input resistance (Rin) | 40KΩ |

| Value of damage | 20V |

| Max. Linearity error | + 0,1% Vfs |

| Max. Offset error | + 0,1% Vfs |

| S.n. | 71 dB |

| Conversion time | It depends on the configuration of the analog input. See section Conversion times if present 1) |

| Isolation | 1000 Vrms |

4.6.4 Connection example

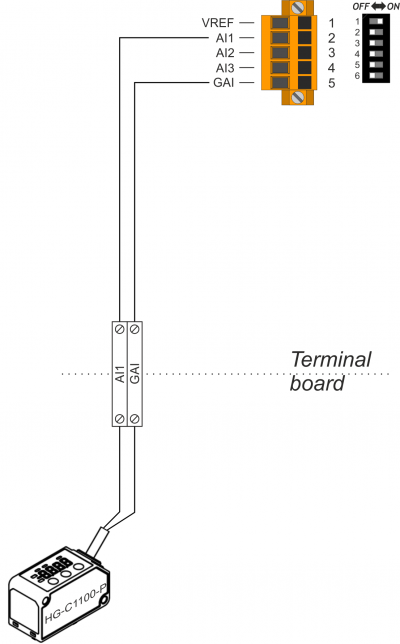

4.6.5 Example of connection of HG-C1100-P laser scanning probe

It is possible to connect a Panasonic HG-C1100-P Micro Laser Distance Sensor to the AI1 input.

The following operations are possible through the laser sensor:

- Surface scan for 3D model (model STL file creation and TXT file with acquired data cloud).

- Scan for surface flatness mapping (creation of surface STL files and TXT files with acquired data cloud).

To function properly the sensor must be reset to the factory settings and analogue input AI1 must be set in 0-20mA amperometric configuration.

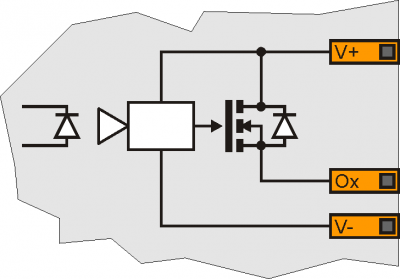

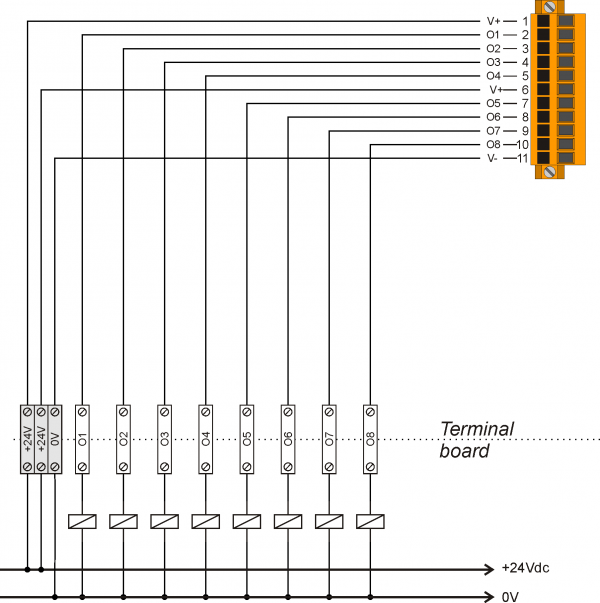

4.7 Digital outputs

The digital outputs, called “User Output ”, can be configured by the RosettaCNC software to make some functions. For example: Spindle start with clockwise rotation, Spindle start with anti-clockwise rotation, air activation, water activation, aux outputs 1.. 4, etc.

4.7.1 32 Protected Outputs

4.7.1.1 CN8

| CN8 | Terminal | Symbol | Description |

|---|---|---|---|

| 1 | V+ | Output power supply input (12÷28V dc) |

| 2 | O9 | 9 User output | |

| 3 | O10 | 10 User output | |

| 4 | O11 | 11 User output | |

| 5 | O12 | 12 User output | |

| 6 | V+ | Output power supply input (12÷28V dc) | |

| 7 | O13 | 13 User output | |

| 8 | O14 | 14 User output | |

| 9 | O15 | 15 User output | |

| 10 | O16 | 16 User output | |

| 11 | V- | Output power supply input (0V dc) |

4.7.1.2 CN9

| CN9 | Terminal | Symbol | Description |

|---|---|---|---|

| 1 | V+ | Outputs power input (12÷28V dc) |

| 2 | O1 | 1 User output | |

| 3 | O2 | 2 User output | |

| 4 | O3 | 3 User output | |

| 5 | O4 | 4 User output | |

| 6 | V+ | Outputs power input (12÷28V dc) | |

| 7 | O5 | 5 User output | |

| 8 | O6 | 6 User output | |

| 9 | O7 | 7 User output | |

| 10 | O8 | 8 User output | |

| 11 | V- | Outputs power input (0V dc) |

4.7.1.3 CN20

| CN20 | Terminal | Symbol | Description |

|---|---|---|---|

| 1 | V+ | Outputs power input (12÷28V dc) |

| 2 | O25 | 25 User Outputs | |

| 3 | O26 | 26 User Outputs | |

| 4 | O27 | 27 User Outputs | |

| 5 | O28 | 28 User Outputs | |

| 6 | V+ | Outputs power input (12÷28V dc) | |

| 7 | O29 | 29 User Outputs | |

| 8 | O30 | 30 User Outputs | |

| 9 | O31 | 31 User Outputs | |

| 10 | O32 | 32 User Outputs | |

| 11 | V- | Outputs power input (0V dc) |

4.7.1.4 CN25

| CN25 | Terminal | Symbol | Description |

|---|---|---|---|

| 1 | V+ | Output power Input (12÷28V dc) |

| 2 | O17 | 17 User Outputs | |

| 3 | O18 | 18 User Outputs | |

| 4 | O19 | 19 User Outputs | |

| 5 | O20 | 20 User Outputs | |

| 6 | V+ | Output power Input (12÷28V dc) | |

| 7 | O21 | 21 User Outputs | |

| 8 | O22 | 22 User Outputs | |

| 9 | O23 | 23 User Outputs | |

| 10 | O24 | 24 User Outputs | |

| 11 | V- | Output power Input (0V dc) |

4.7.1.5 Electrical features

| Type | PNP |

| Maximum operating voltage | 28V |

| Maximum internal voltage drop | 600mV |

| Maximum current | 500mA |

| Maximum switching time from ON to OFF | 270µs |

| Maximum switching time from OFF to ON | 250µs |

4.7.1.6 Connection examples

4.7.2 STEP-DIRECTION Outputs

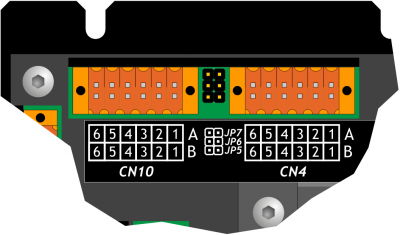

4.7.2.1 CN10

| Description | Symbol | Terminal | CN10 | Terminal | Symbol | Description | ||

|---|---|---|---|---|---|---|---|---|

| External STEP/DIR Power outputs | VDx | 1A |  | 1B | VDx | External STEP/DIR Power outputs | ||

| PNP / Line Driver | X DIRECTION Output | DIR1+ | 2A | 2B | DIR1- | X Complementary DIRECTION Output | Complementary Outputs for use in drives with Line Driver inputs | |

| X STEP Output | STEP1+ | 3A | 3B | STEP1- | X Complementary STEP Output | |||

| Y DIRECTION Output | DIR2+ | 4A | 4B | DIR2- | Y Complementary DIRECTION Output | |||

| Y STEP Output | STEP2+ | 5A | 5B | STEP2- | Y Complementary STEP Output | |||

| Common of Stepper outputs | 0V | 6A | 6B | 0V | Common of Stepper outputs | |||

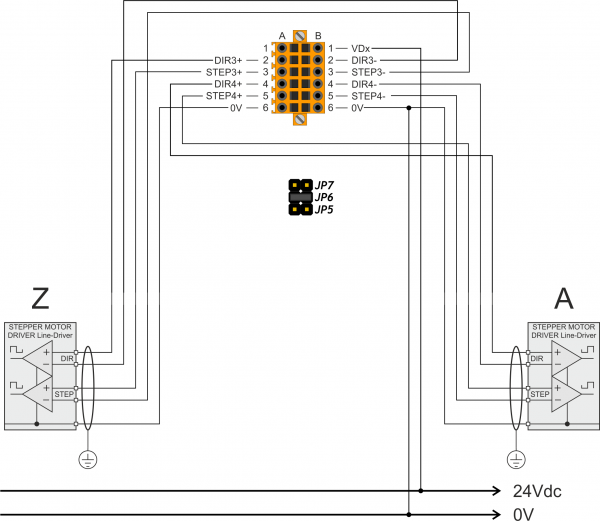

4.7.2.2 CN4

| Description | Symbol | Terminal | CN4 | Terminal | Symbol | Description | ||

|---|---|---|---|---|---|---|---|---|

| External STEP/DIR Power outputs | VDx | 1A |  | 1B | VDx | External STEP/DIR Power outputs | ||

| PNP / Line Driver | Z DIRECTION Output | DIR3+ | 2A | 2B | DIR3- | Z Complementary DIRECTION Output | Complementary Outputs for use in drives with Line Driver inputs | |

| Z STEP Output | STEP3+ | 3A | 3B | STEP3- | Z Complementary STEP Output | |||

| A DIRECTION Output | DIR4+ | 4A | 4B | DIR4- | A Complementary DIRECTION Output | |||

| A STEP Output | STEP4+ | 5A | 5B | STEP4- | A Complementary STEP Output | |||

| Common of Stepper outputs | 0V | 6A | 6B | 0V | Common of Stepper outputs | |||

4.7.2.3 CN11

| Description | Symbol | Terminal | CN11 | Terminal | Symbol | Description | ||

|---|---|---|---|---|---|---|---|---|

| External STEP/DIR Power outputs | VDx | 1A |  | 1B | VDx | External STEP/DIR Power outputs | ||

| PNP / Line Driver | B DIRECTION Output | DIR5+ | 2A | 2B | DIR5- | B Complementary DIRECTION Output | Complementary Outputs for use in drives with Line Driver inputs | |

| B STEP Output | STEP5+ | 3A | 3B | STEP5- | B Complementary STEP Output | |||

| C DIRECTION Output | DIR6+ | 4A | 4B | DIR6- | C Complementary DIRECTION Output | |||

| C STEP Output | STEP6+ | 5A | 5B | STEP6- | C Complementary STEP Output | |||

| Common of Stepper outputs | 0V | 6A | 6B | 0V | Common of Stepper outputs | |||

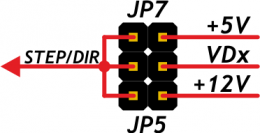

4.7.2.4 STEP-DIRECTION Output voltage Setting

Inserting one of the JP3, JP4 o JP5 jumpers, You can choose the operating voltage of the STEP and DIR outputs.

Only one jumper must be inserted at a time

If one of the two voltages is selected, 5V(JP5) or 12V(JP3), both the 1A and 1B terminals must remain disconnected.

.

4.7.2.5 Electrical features

| Polarization type | PNP / Line-Driver |

| Maximum output frequency | 1MHz to 5volt, 300KHz to 12 or 24 volt |

| Insulated | 1000Vpp |

| Maximum operating current | 20mA |

| Maximum VDX voltage | 27Vdc |

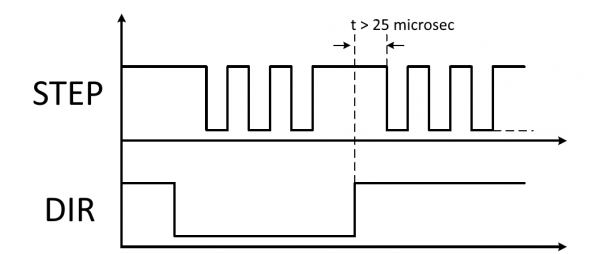

Step signal during the change of direction:

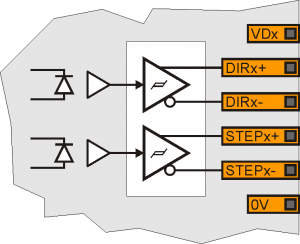

Internal diagram of Stepper motor control outputs:

4.7.2.6 Connection examples

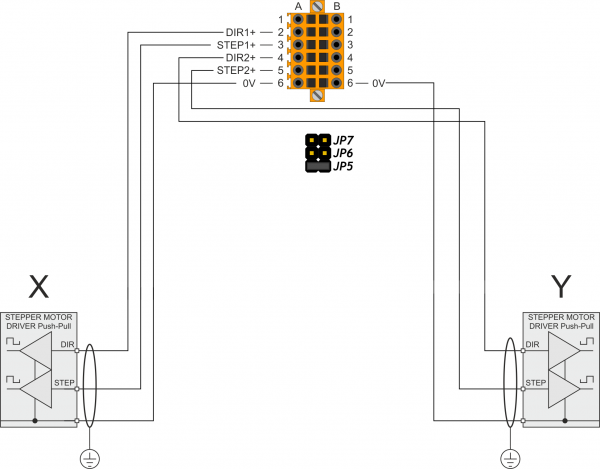

X and Y PNP to 12Vdc Axes

The voltage level of the outputs is selected via the JP5 jumper

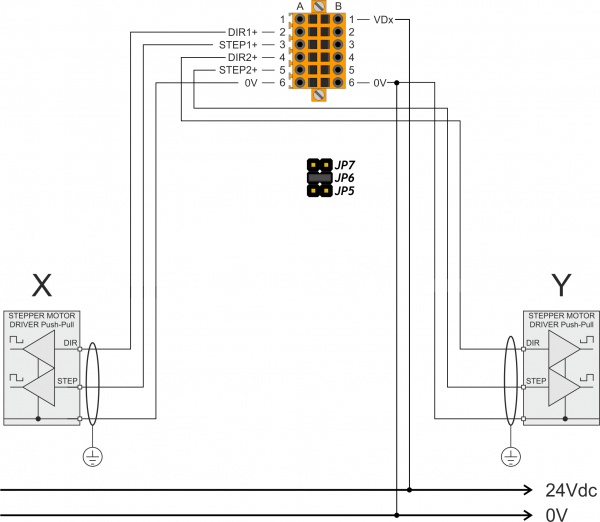

X and Y PNP to 24Vdc Axes

The voltage level of the outputs, by selecting the jumper JP6, is equal to the voltage supplied to terminals 1A or 1B

A and Z Line-Driver to 5Vdc Axes

The voltage level of the outputs is selected via the JP7 jumpers

A and Z Line-Driver to 24Vdc Axes

The voltage level of the outputs is selected via the JP6 jumpers

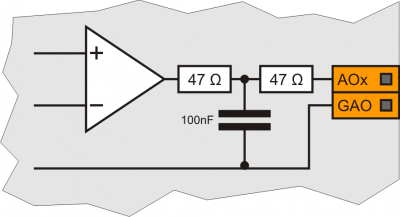

4.8 Analog outputs

4.8.1 Connector

| CN12 | Terminal | Symbol | Description |

|---|---|---|---|

| 1 | GAO | Common of analog outputs |

| 2 | AO1 | Analog outputs 1 | |

| 3 | AO2 | Analog outputs 2 | |

| 4 | GAO | Common of analog outputs | |

| 5 | AO3 | Analog outputs 3 | |

| 6 | AO4 | Analog outputs 4 |

| CN24 | Morsetto | OPZIONE ESPANSIONE I/O = “1” | OPZIONE ESPANSIONE “A/1” | ||||

|---|---|---|---|---|---|---|---|

| Simbolo | Descrizione | Simbolo | Descrizione | ||||

| 1 | GAO | Comune uscite analogiche | GAO | Comune uscite analogiche | ||

| 2 | AO5 | Uscita analogica 5 | AO5 | Uscita analogica Asse A | |||

| 3 | AO6 | Uscita analogica 6 | AO6 | Uscita analogica Asse B | |||

| 4 | GAO | Comune uscite analogiche | GAO | Comune uscite analogiche | |||

CN24 connector available only with field I/O Expansion = 1, in order code.

4.8.2 Electrical features

| Connection type | In a common mode |

| Insulated | 1000Vrms |

| Voltage range (minimum empty) | 0÷10V |

| Maximum offset variation depending on temperature | +/- 5mV |

| Resolution | 16bit |

| Maximum current | 1mA |

| Variation of output depending on load | 100 µV/mA |

| Output resistance | 249Ω |

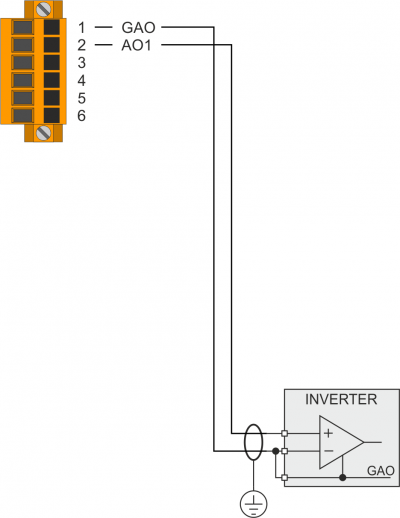

4.8.3 Connection examples

Analogue output Connection to an inverter

5. Connection and configuration examples

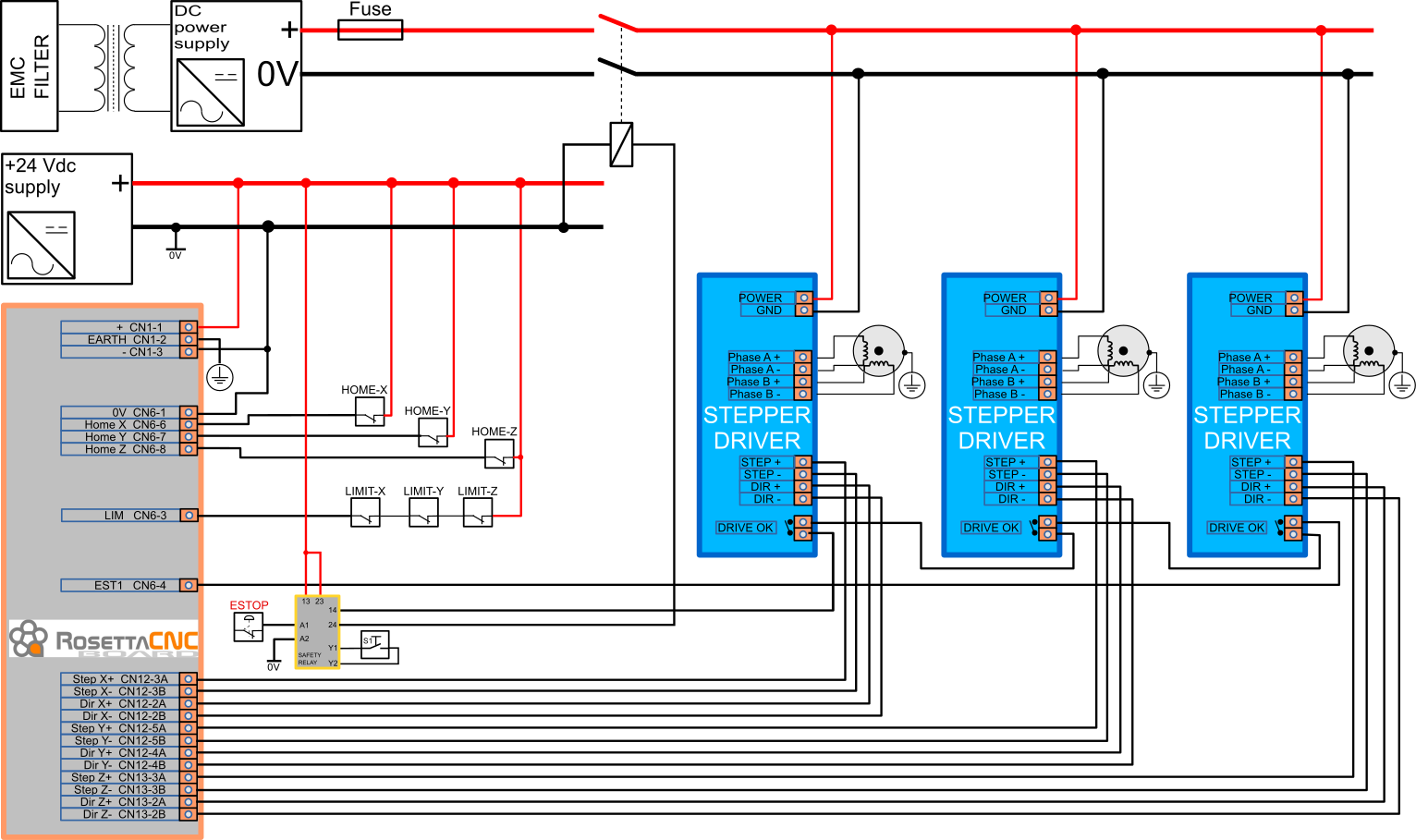

Below we will illustrate some useful wiring diagrams as an example for the design of the complete control system (electric panel).

5.1 Connecting of an XYZ pantograph

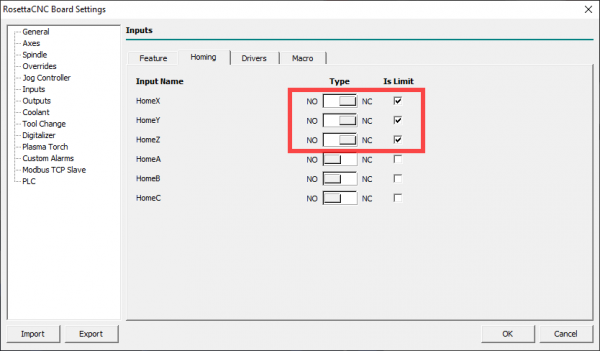

In the following example we see a wiring diagram of three stepper drives. The HOME switches are also used as a limit for the direction of movement where the homing procedure is executed. For the other direction, uses three NC switches in series and connected with the LIM input.

In this case the correct setting of the inputs in the configuration panel will be:

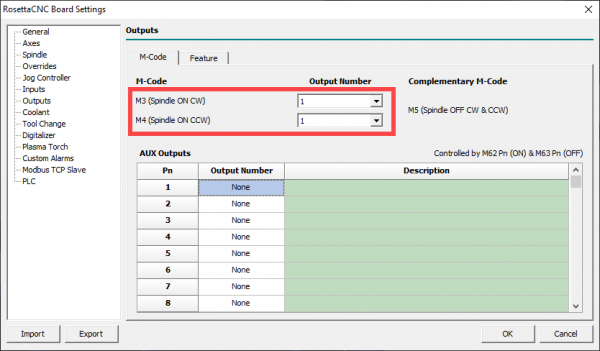

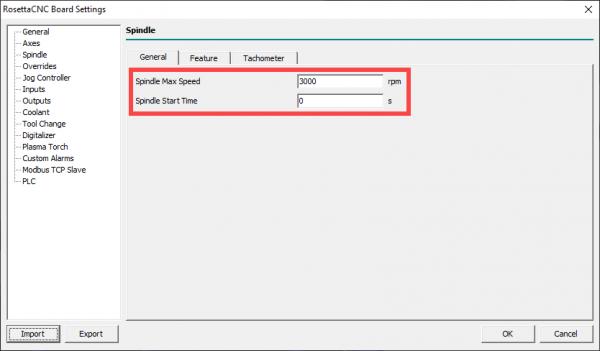

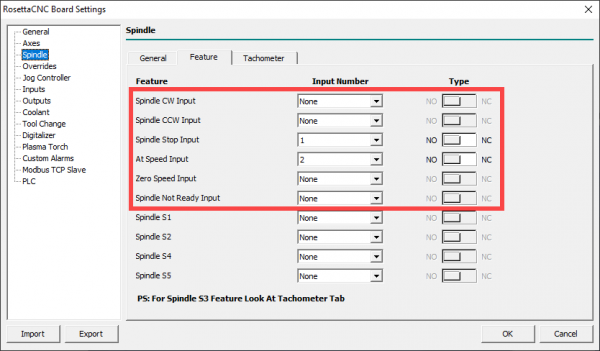

5.2 Configuring the Spindle command

The following outputs are available for the spindle control:

- Digital output for clockwise rotation control

- Digital output for counterclockwise rotation control

- Analog output for Speed variation

The choice of the digital outputs to use for these functions is performed in the “Outputs” panel in “RosettaCNC card settings” As shown in the picture:

The M3 or M4 codes will activate the outputs, M5 will disable them.

If RosettaCNC Board controls also the spindle rotation speed then you must connect the analog output 0÷10V to the analog input of the drive.

In the maximum speed parameter, you must set the the speed reached by the drive to the maximum voltage of 10V.

The “Start Time” parameter if set delays the execution of the Gcode to allow the spindle to reach the set speed. This time is also used when turning off the spindle.

In RosettaCNC Board are available also two digital inputs that can be used to inform the Controller when the spindle has reached the set speed or when it's stopped.

The following picture shows where to set the reference speed to 10V, The start time and the configuration of the inputs:

If the inputs are configured then the value in the start time parameter always indicates the minimum wait time although the logic level of the input does not require a wait.

5.3 Control console connection

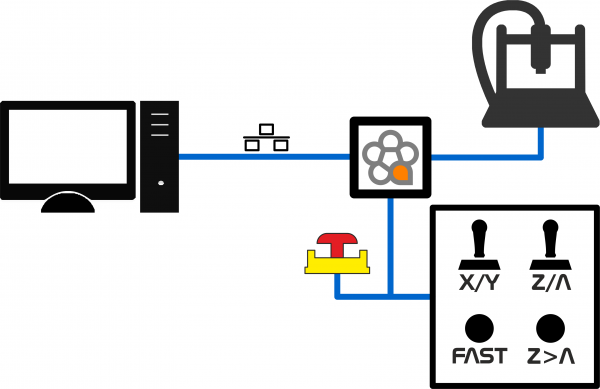

The following shows four examples:

- The easiest way is to always operate in the personal computer where the software RosettaCNC is installed. Here will be commanded the Jogs, the homing sequences, starting and stopping the Gcode programs, etc. Below is a graphical representation of the solution:

.

.

On the machine side only the ESTOP emergency button will be present (and possibly the reset button). In addition, MPG devices can be set up to control the override (up to four devices), or analogue potentiometers (up to three devices). In this case the value of the “Controller type” parameter is not significant. The CN19 connector remains unconnected and the CN17 connector can be used as MPG1.

- With the following solution, the following control devices are wired near the machine (in addition to the ESTOP emergency button): Joystick for the X-Y-Z jog. A button for selecting Jog Fast speeds. Possible button to modify the joystick control Z in A B or C. The following is a graphical representation of the solution:

.

.

In addition an MPG device can be set up for control of override (up to three devices), or analogue potentiometers (up to three devices). In this case the value of the “Controller type” parameter must be set to “Dual Joystick”.

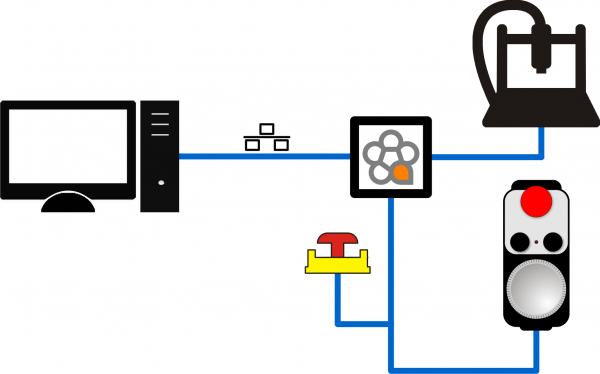

- With the following solution a handwheel is installed near the machine to check manual movements. During operation, if set in configuration, the handwheel can also be used to control the override (configuring the operation of the MPG1 device). Finally, always if set in configuration the handwheel button can also be used to perform a reset of the selected axis. The following is a graphical representation of the solution:

.

.

In addition to the flyer, an MPG device for override control can be set up near the machine (up to three devices), or analogue potentiometers (up to three devices). In this case, the value of the “Controller type” parameter must be set to “HandWheel A”.

- With the following solution, the following control devices are wired near the machine (in addition to the ESTOP emergency button): a Joystick for the jog+ and Jog-. Up to six buttons for axis selection. A button to reset the axis. The following is a graphical representation of the solution:

.

.

In addition, an MPG device can be set up to control the override (up to four devices), or analogue potentiometers (up to three devices). In this case the value of the “Controller type” parameter must be set to “Single Joystick”.

6. Diagnostic

- Green Led POW, indicates that the device is powered.

- Green Led RUN, indicates that the device is working.

- Yellow Led STOP, indicates that the device is in a stop state.

- If flashes the Red Led ERROR, the controller is in an error state. You can try turning off and on again, if the problem persists, the product should be sent to technical support through the purchase channel used.

7. Virtul Inputs Outputs

The firmware implements a series of virtual user inputs and outputs that can be used with Modbus ® communication.

Below is the list of virtual user inputs and their relationship with the numbering of virtual inputs in Modbus ®.

| User input number | Virtual input number |

|---|---|

| 51 | 01 |

| 52 | 02 |

| 53 | 03 |

| 54 | 04 |

| 55 | 05 |

| 56 | 06 |

| 57 | 07 |

| 58 | 08 |

| 59 | 09 |

| 60 | 10 |

| 61 | 11 |

| 62 | 12 |

| 63 | 13 |

| 64 | 14 |

Below is the list of virtual user outputs and their relationship with the virtual output numbering in Modbus ®.

| User outputs number | Virtual outputs number |

|---|---|

| 33 | 01 |

| 34 | 02 |

| 35 | 03 |

| 36 | 04 |

| 37 | 05 |

| 38 | 06 |

| 39 | 07 |

| 40 | 08 |

8. Index Inputs

Starting from 1.52 firmware version it is possible to use these user inputs as index during homing.

| User Inputs number | Connector |

|---|---|

| 27 | CN14 |

| 30 | CN15 |

| 50 | CN16 |

| 43 | CN17 |

| 49 | CN22 |

| 46 | CN21 |

9. Accessory IQ023

Starting from software version 1.9.4 it is possible to connect the IQ023 accessory to the control PC.

The use of this accessory must be enabled in the board settings.

The resources of the accessory are mapped as follows:

| Resource IQ023 | Signal |

|---|---|

| D01 | User input 65 |

| D02 | User input 66 |

| D03 | User input 67 |

| D04 | User input 68 |

| D05 | User input 69 |

| D06 | User input 70 |

| D07 | User input 71 |

| D08 | User input 72 |

| D09 | User input 73 |

| D10 | User input 74 |

| D11 | User input 75 |

| D12 | User input 76 |

| D13 | User input 77 |

| D14 | User input 78 |

| D15 | User input 79 |

| D16 | User input 80 |

| D17 | User input 81 |

| D18 | User input 82 |

| D19 | User input 83 |

| D20 | User input 84 |

| D21 | User input 85 |

| D22 | User input 86 |

| D23 | User input 87 |

| D24 | User input 88 |

| E1A Phase A MPG 1 | User input 89 |

| E1B Phase B MPG 1 | User input 90 |

| E2A Phase A MPG 2 | User input 91 |

| E2B Phase B MPG 2 | User input 92 |

| E3A Phase A MPG 3 | User input 93 |

| E3B Phase B MPG 3 | User input 94 |

| E4A Phase A MPG 4 | User input 95 |

| E4B Phase B MPG 4 | User input 96 |

| A0 | Analog input 04 |

| A1 | Analog input 05 |

| A2 | Analog input 06 |

| A3 | Analog input 07 |

| A4 | Analog input 08 |

| A5 | Analog input 09 |

| A6 | Analog input 10 |

| A7 | Analog input 11 |

| MPG 1 | MPG 5 |

| MPG 2 | MPG 6 |

| MPG 3 | MPG 7 |

| MPG 4 | MPG 8 |

10. Grants

We thank in advance all those who want to contribute to the improvement of this documentation by indicating inaccuracies or contents. Write to the address: support@rosettacnc.com