This is an old revision of the document!

12. Plasma Torch

Starting from version 1.7 the management of the Plasma Torch has been added.

For plasma management it is possible to add an external THC (Torch Height Control) device to obtain control of the torch height.

An example of a widely used THC device could be the THC 150 model of the Proma Elektronika company.

The THC 150 provides three output digital signals to the CNC:

- UP: The torch must be raised.

- DOWN: The torch must be lowered.

- ARC: The arc under the torch is active.

All these digital signals are connected to the RosettaCNC user inputs.

The number of the user input to be used is not restricted, in the RosettaCNC settings it will be necessary to set the number of the user input chosen for each signal.

12.1 Plasma Torch and Spindle

The management of the Plasma Torch is decoupled from the management of Spindle, therefore it is possible to have mounted in same head of CNC a normal Spindle and a Plasma Torch.

Spindle and Plasma Torch have separate digital output signals but share same activation/deactivation G-code (M3 and M5).

When the loaded tool is of type Plasma M3 become Torch ON command and M5 will be Torch OFF command. M4 will have same behavior of M5.

Also the Spindle CW Input, Spindle CCW Input and Spindle Stop Input will be disabled.

When the loaded tool is of any other type M3 become Spindle CW and command M5 will be Spindle Stop. M4 will be Spindle CCW.

The Spindle CW Input, Spindle CCW Input and Spindle Stop Input if configurated will be enabled.

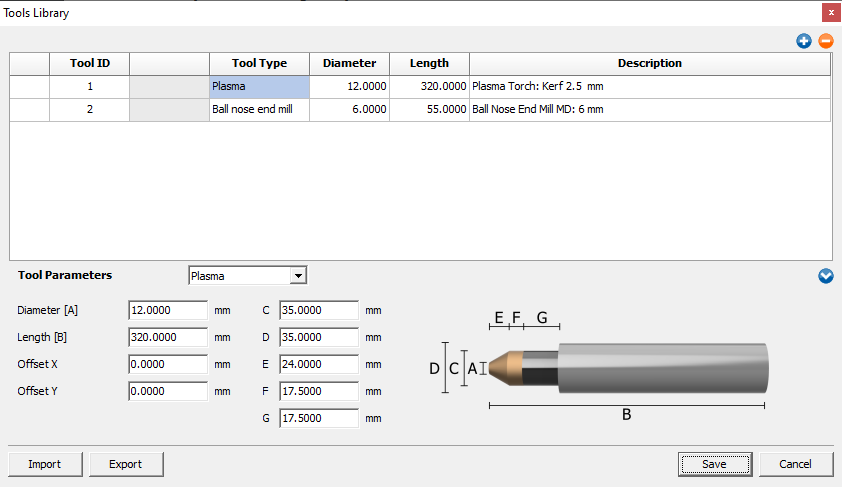

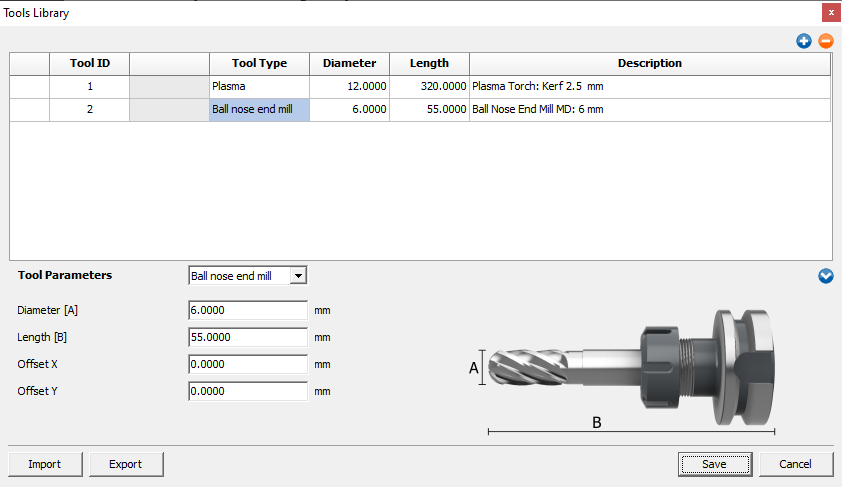

To work with Plasma Torch is necessary to correctly define and load a Plasma tool.

This requires that the Tool Change Type parameter, in the Tool Change panel on RosettaCNC Board Settings, is set to Macro and that the tool change macro is correctly configurated for your machine.

12.2 Configuration

The configuration of Plasma Torch and Torch Height Control is defined in the Plasma Torch panel in the RosettaCNC tab settings.

Let's see in detail the meaning of each parameter:

- Torch Velocity : Indicates the Z axis velocity when it is controlled by the THC. It is a percentage value of Z axis maximum speed.

- Torch Disable Velocity : Indicates a percentage of the feed set which the THC control is automatically disabled. Setting zero to disable the function. For more details see the dedicated chapter.

- Torch Acceleration Override : Indicates the acceleration of the Z axis during the THC check. 100% means as axis setting, 50% means half acceleration.

- Torch Up Input : It is the number of the user input and the type of logic dedicated to this function.

- Torch Dwon Input : It is the number of the user input and the type of logic dedicated to this function.

- Torch Arc OK Input : It is the number of the user input and the type of logic dedicated to this function. Its programming is optional. For more details see the dedicated chapter.

- Torch Anti-Collision Input : It is the number of the user input and the type of logic dedicated to this function. Its programming is optional. If the THC control is active (

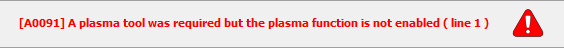

M17) RosettaCNC continuously monitors the signal and if it indicates a collision, the machining is immediately stopped and the alarm would appear:

- M3 (Plasma Torch ON) : It is the number of user output that sets the plasma torch state.

- M17 (Torch Control Height ON) : It is also possible to configure a digital output that is activated when the Z axis is controlled by the THC device.

12.3 Operation

The CNC enters in Plasma Mode when a tool of PLASMA type il loaded with Tn M6 or M61 Qn G-code instructions.

The CNC exits from Plasma Mode when any other type of tool is loaded with Tn M6 or M61 Qn G-code instructions.

During PLASMA tool loading the CNC checks if Enable Plasma Torch setup parameter is OFF, in this case the CNC will enters in ALARM state:

When CNC is in Plasma Mode:

M3actives the Plasma Torch output.

M4/M5deactives the Plasma Torch output.

M17enables the THC device control of Z axis height.

M18disables the THC device control of Z axis height.

The M17 instruction activates the Z axis control by THC. When this instruction is encountered, RosettaCNC saves the current Z axis position, then disconnects the axis from the interpolation and commands it via the Up torch and Down torch inputs. When the instruction M18 is met RosettaCNC maintains the current position up to a new command Z instruction inside the G-code. During the THC check, a digital output, if configured, is activated to manage any external electromechanical logic.

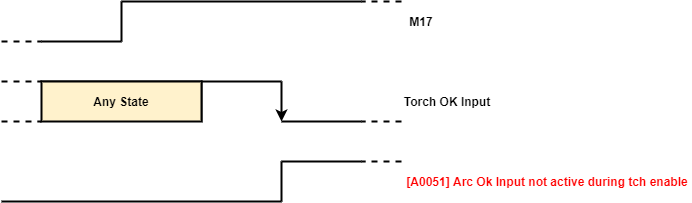

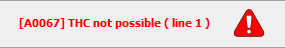

The G-code instruction M17 can place CNC in ALARM state:

This happens in the following cases:

- The Z axis is not enabled in the settings.

- The “Enable plasma Torch” parameter is not active.

- Up Torch or Down Torch inputs have not been configured.

12.3.1 "Torch Arc Ok" Input

The Torch Arc OK input signal can be set to any generic user input or leaved NOT configured in the “Plasma torch” panel.

When assigned to an user input it is possible to wait and verify that the arc is activated by, for example, instruction M66 P1 L1 after power on the torch with M3.

However, if you wish also that RosettaCNC continuously verifies the presence of the “Torch Arc Ok” input signal when the THC is active, then it must be configured.

In this way you can continue to use the check with instruction M66 P1 L1 and if the arc became not active, an alarm during THC enable is generated

.

.

In other words, while the THC is active, if the “Torch Arch Ok” signal becomes or is already active, it can no longer be deactivated until the THC is disabled.

12.3.2 Z position after M18

When the THC is active, the Z position assumes a value different from that expressed by the G-code.

The M18 command (that deactivates the THC) must also return the Z position to the value expressed by the G-code.

This movement takes place in the following way: at the first movement instruction following the code M18 (even if it does not explicitly include the letter Z) the CN performs a check if an upward movement is necessary to reach the target position.

In the negative case (negative movement need) the CNC enters in ALARM state:

Otherwise the new movement includes a movement of Z from the current position to the new target position expressed in the G-code.

So in general it is necessary to verify in the post processor that the first move instruction after M18 includes a climb movement Z to a safety altitude.

12.3.3 Torch Disable Velocity

The Torch Disable Velocity parameter, when greater than 0%, enables continuous monitoring of the interpolation feed rate.

During movements with THC Control Enabled (M17) if interpolation feed rate decreases by percentage respect to the set value, the CNC automatically suspends the THC Control.

This is useful if the feed speed is decreased by the interpolator to respect the axis accelerations, for eg.during an axis direction change.

Let's take an example:

- Set the Torch Disable Velocity parameter to 80%.

- The plasma cutting to be performed has been described in the G-Code program with

F1000. - Suppose we work with Feed Override at 100%.

- If, for example, during an axis change direction the feed rate decreases below 800mm/min the THC UP/DOWN signals are temporary ignored till the speed returns at least to 800mm/min.

Another example:

- Set the Torch Disable Velocity parameter to 80%.

- The plasma cutting to be performed has been described in the G-Code program with

F3000. - During the cut the operator sees that the best result is obtained with a 70% Override (therefore 2100mm/min).

- If the feed rate decreases below 1680mm/min (80% of 2100) the THC UP/DOWN signals will be temporary ignored till the speed returns at least to 1680mm/min.

12.4 Torch Toolbar Icon

It is possible to have in the toolbar the icon of Plasma Torch output state enabling related icon Visible checkbox on Toolbar View panel of Program Settings.

It is also possible to enable the icon to change Plasma Torch output state enabling realeted icon Enabled checkbox.

The change of Plasma Torch output state between icon toolbar will be possibile ONLY when CNC is in IDLE state.

Resulting toolbar view:

12.5 THC Disable Toolbar Icon

It is possible to have in the toolbar the icon of THC Disable control enabling related icon Visible checkbox on Toolbar View panel of Program Settings.

It is also possibile to enable the icon to change the THC Disable state enabling related icon Enabled checkbox.

The change of THC disable state is possible both before the execution of a G-code and during the execution of a G-code.

If the THC is disabled the Z axis keep the position.

Resulting toolbar view:

The set disable state is not kept after a CNC shutdown.

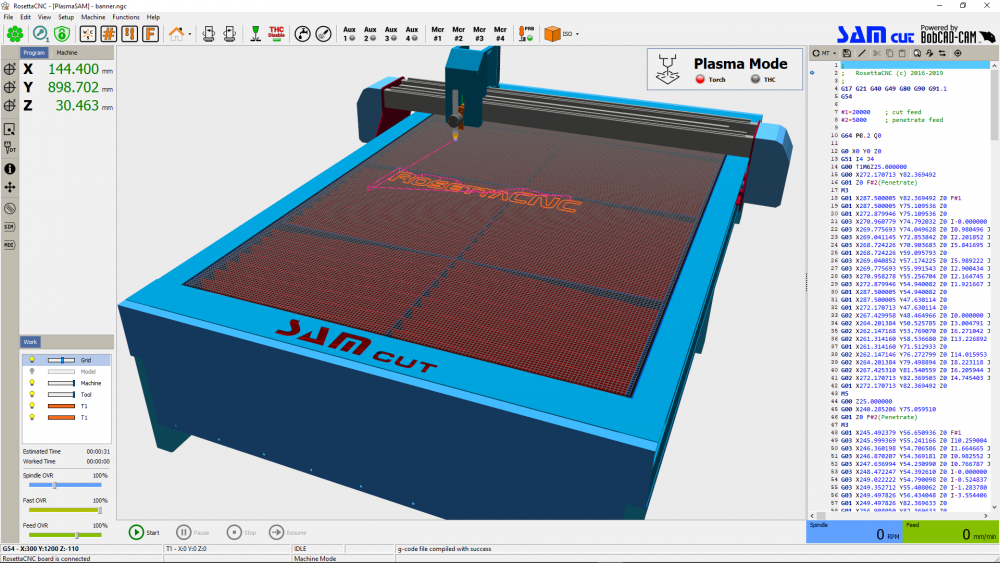

12.6 UI View

When a Plasma Torch tool is active an extra panel is shown at top/right place in toolpath scene.

The panel indicates that CNC is in Plasma mode and two LEDs show the Plasma Torch and THC control state.

An overall view of Plasma Torch CNC is the following:

12.7 Important Notes

- At the end of the G-code the THC control is automatically disabled.

- When the THC is enabled (

M17) any programmed Z movement in the G-code will be ignored. - During the THC control the Z movements can extend between the minimum machine position and the maximum machine position value.

- If the “Torch Up Input” and “Torch Down Input” are active simultaneously (abnormal condition) no movement is performed and no alarm is generated.