6. Canned Cycles

A canned cycle is a command that gives the machine instructions for a pattern of movements.

It’s meant to automate and simplify repetitive and common tasks, such as drilling holes.

Instead of programming every movement and function individually, a canned cycle controls a set of motions.

In this section you can find a quick reference list followed by a paragraph for every cycle explaining how to use it properly.

6.1 List of supported Canned Cycles

| G-code | Description |

|---|---|

| G73 | Drilling - High Speed Peck Drilling Cycle / Chip Break Drilling Cycle |

| G80 | Cancel Motion Mode / Canned Cycle Cancel |

| G81 | Drilling - Standard Drilling |

| G82 | Drilling - Drilling Cycle, Dwell |

| G83 | Drilling - Peck Drilling Cycle |

| G85 | Boring - Boring Cycle, Feed Out |

| G86 | Boring - Boring Cycle, Spindle Stop, Rapid Move Out |

| G88 | Boring - Boring Cycle, Spindle Stop, Manual Out |

| G89 | Boring - Boring Cycle, Dwell, Feed Out |

| G98 | Canned Cycle – Retract Back To The Initial Z |

| G99 | Canned Cycle – Retract Back To R Plane |

6.2 G73 High Speed Peck Drilling Cycle

G73 High Speed Peck Drilling cycle performs high–speed peck drilling.

It performs intermittent cutting feed to the bottom of a hole while removing chips from the hole.

Programming

G73 X Y Z R Q F <L>

Parameters

| Parameter | Description |

|---|---|

| X Y | Hole position data |

| Z | Z-depth (feed to Z-depth starting from R plane) |

| R | The distance from the initial level to point R level (Position of the R plane) |

| Q | Depth of cut for each cutting feed (depth of each peck) |

| F | Cutting feedrate |

| L | Number of repeats (if required) |

Cycle Operation

The tool dips into the workpiece for the infeed Q, drives back with rapid feed of 0.254mm (d retraction) to break chips, dips in again, until end depth is reached, then retracts with rapid feed.

Example

N10 G99 G73 X10 Y10 Z-8 R2 Q1 F100 N20 X20 N30 X30

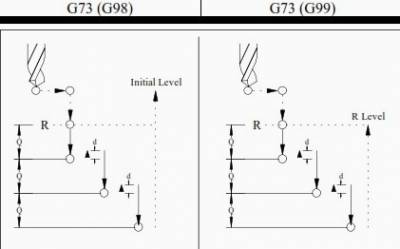

G98 G99

When G98 is active, the Z-axis will return to the start position (initial plane) every time it completes a single operation.

When G99 is active, the Z-axis will be returned to the R point (plane) every time the canned cycle completes a single hole. Then the machine will go to the next hole.

Generally, G99 is used for the first drilling operation and G98 is used for the last drilling operation.

6.3 G80 Cancel motion mode / Canned Cycle Cancel

To cancel a canned cycle you can use G80 or one of the following G-codes from Group 01:

| G-code | Description |

|---|---|

| G0 | Straight traverse |

| G1 | Straight feed |

| G2 | Clockwise arc feed |

| G3 | Counterclockwise arc feed |

| G38.x | Probing |

| G80 | Cancel motion mode / Canned Cycle Cancel |