4. Cutter compensation

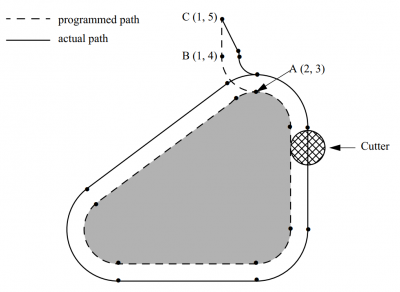

The cutter radius compensation capabilities of the Interpreter enable the programmer to specify that a cutter should travel to the right or left of an open or closed contour composed of arcs of circles and straight line segments, all planes are supported XY, YZ and XZ.

4.1 G41, G42 Cutter Compensation

G41 <D> <I>left of programmed pathG42 <D> <I>right of programmed path

Notes

D- tool numberI- dynamic radius offset- The D word is optional; if there is no D word the radius of the currently loaded tool will be used (if no tool is loaded and no D word is given, a radius of 0 will be used).

- The I word is optional; if there is I word the resulting radius will be: “table diameter value” / 2 - “I value”.

- If supplied, the D word is the tool number to use. This would normally be the number of the tool in the spindle (in which case the D word is redundant and need not be supplied), but it may be any valid tool number.

- It is an error if:

- The D number is not a valid tool number or 0.

- Cutter compensation is commanded to turn on when it is already on.

4.2 G41.1, G42.1 Dynamic Cutter Compensation

G41.1 D <L>(left of programmed path)G42.1 D <L>(right of programmed path)

Notes

D- cutter diameterL- tool orientation (see lathe tool orientation)- G41.1 & G42.1 function the same as G41 & G42 with the added scope of being able to program the tool diameter. The L word defaults to 0 if unspecified.

- It is an error if:

- The YZ plane is active.

- The L number is not in the range from 0 to 9 inclusive.

- The L number is used when the XZ plane is not active.

- Cutter compensation is commanded to turn on when it is already on.

4.3 Tool compensation entry options

- Three compensation entry option are supported:

- NIST

- The default NIST mode.

- Easy Lead-In

- Delays the first movement of the entry move until the following line or arc is specified.

- When the second entry motion is specified it performs the entry move to a position tangent to the beginning of the second line or arc.

- This option works well with some CADs such as Fusion360 indeed not gouging errors are generated.

- Normal

- It is the only option that can handle concave corners and concave arcs.

The Easy lead-In option is needed when a concave corner is present between the first and the second move that is part of the Lead-in.

Common Cutter Radius Compensation Errors

When the first two options are selected and cutter radius compensation is on, it must be physically possible for a circle whose radius is

the half the diameter given in the tool table to be tangent to the contour at all points of the contour.

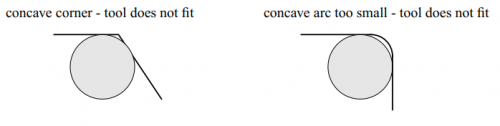

In particular, the Interpreter treats concave corners and concave arcs into which the circle will not

fit as errors, since the circle cannot be kept tangent to the contour in these situations.

This error detection does not limit the shapes which can be cut, but it does require that the programmer specify the actual shape to be cut (or path to be followed), not an approximation.

In both examples, the line represents a contour, and the circle represents the cross section of a tool following the contour using cutter radius compensation (tangent to one side of the path.)

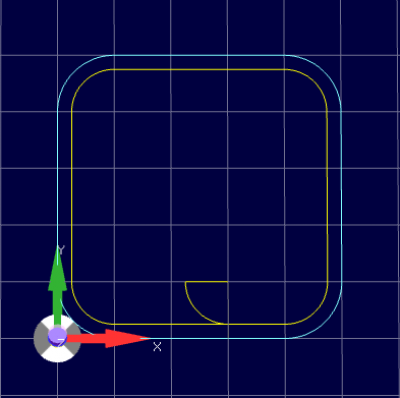

4.4 Examples

4.4.1 Easy Lead-in

( © 2018 by RosettaCNC Motion ) ( file name: cutter_compensation.ngc ) G21 G40 G49 G90 G54 G50 G69 G0 x10y0z0 T0 M6 F2000 ( Non compensated square ) M98 P1000 G0 x30y10z0 T1 M6 G41 D1 ( Lead- in moves ) G1X20Y10 G3X30Y0I10J0 ( Compensated square ) M98 P1000 G40 G0X30y10z0 M30 ( Square with rounded corners ) O1000 G1X40 G3X50Y10I0J10 G1Y40 G3X40Y50I-10J0 G1X10 G3X0Y40I0J-10 G1Y10 G3X10Y0I10J0 G1X30 M99

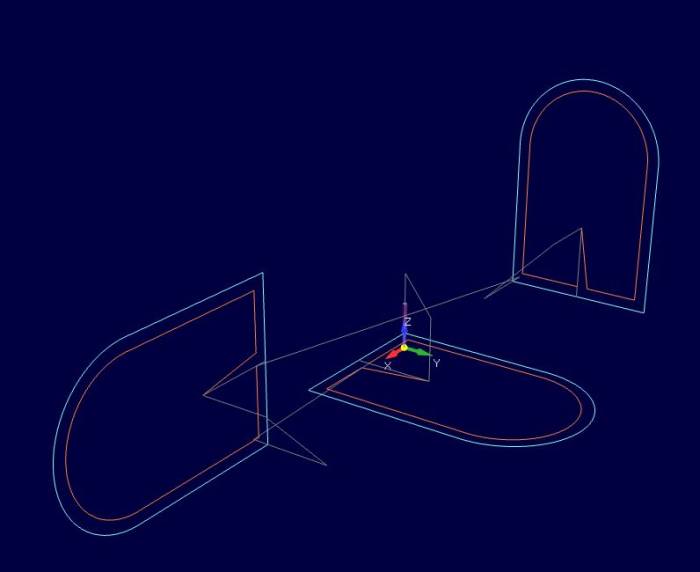

4.4.2 Auto

( © 2018 by RosettaCNC Motion ) ( file name: automatic_compensation.ngc ) ( G-code with cutter comensation example in all planes ) ( Note: for a real work the cutter compensation lead-in ) ( move should be added manually. ) G17 G21 G40 G49 G90 G54 G50 G69 ; XY plane G17 G00 Z50 G00 X50 Y50 M6 T0 F1000. S500 G00 Z10 M98 P1 ; Normal window G00 X50 Y50 M6 T3 F1000. S500 G01 Z10 G41 M98 P1 ; Compensated window G40 G52 X150 G00 X0 Y0 Z0 ; XZ Plane G18 G00 Y50 G00 Z50 X50 M6 T0 G00 Y10 M98 P2 ; Normal window G00 Z50 X50 M6 T3 F1000. S500 G01 Y10 G41 M98 P2 ; Compensated window G40 G52 X-150 G00 X0 Y0 Z0 ; YZ Plane G19 G00 X50 G00 Y50 Z50 M6 T0 G00 X10 M98 P3 ; Normal window G00 Y50 Z50 M6 T3 F1000. S500 G01 X10 G41 M98 P3 ; Compensated window G40 M2 O1 ; Gothic window XY G91 G01 Y-50 X50 Y100 G03 X-100 R50 G01 Y-100 X50 G90 M99 O2 ; Gothic window XZ G91 G01 X-50 Z50 X100 G03 Z-100 R50 G01 X-100 Z50 G90 M99 O3 ; Gothic window YZ G91 G01 Z-50 Y50 Z100 G03 Y-100 R50 G01 Z-100 Y50 G90 M99