This is an old revision of the document!

RosettaCNC - Control software

Information

|

|||

| Document: | MDUROSETTACNCCONTROLSOFTWARE | ||

|---|---|---|---|

| Description: | RosettaCNC Control SOFTWARE | ||

| Link: | https://wiki.rosettacnc.com/en/software/mdurosettacncsoftware | ||

| Release documento | Descrizione | Note | Data |

| 01 | First release | / | 18/05/2021 |

| 02 | Update | / | 16/01/2022 |

| 03 | Update | / | 10/11/2022 |

References

This manual explains the Control Software used by the RosettaCNC Board.

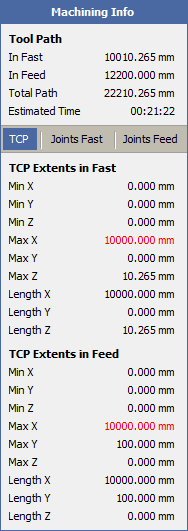

All the implementation details refer to the software version: 1.12.1.

The current version of the Control Software can be identified by opening the Help → About menu:

|

1. System Overview

The RosettaCNC System is composed of 4 main parts:

- The CNC Board.

- The Control Software.

- The Communications Service.

- The Plugin Industry 4.0 (optional).

1.1 The CNC Board

The CNC Board, or simply the “Board”, is a complete CNC controller built over a proprietary powerful Industrial Real-Time Operating System called QMOS.

It contains all features to manage independently the Axes Interpolations, the Smoothing Engine, Jerk Control, and RTCP algorithms, the Digitals and Analogs I/O, the Modbus, and EtherCAT Fieldbus, and so on.

The Board communicates with the other parts of the system using a fast and secure multi-port ETH connection.

1.2 The Control Software

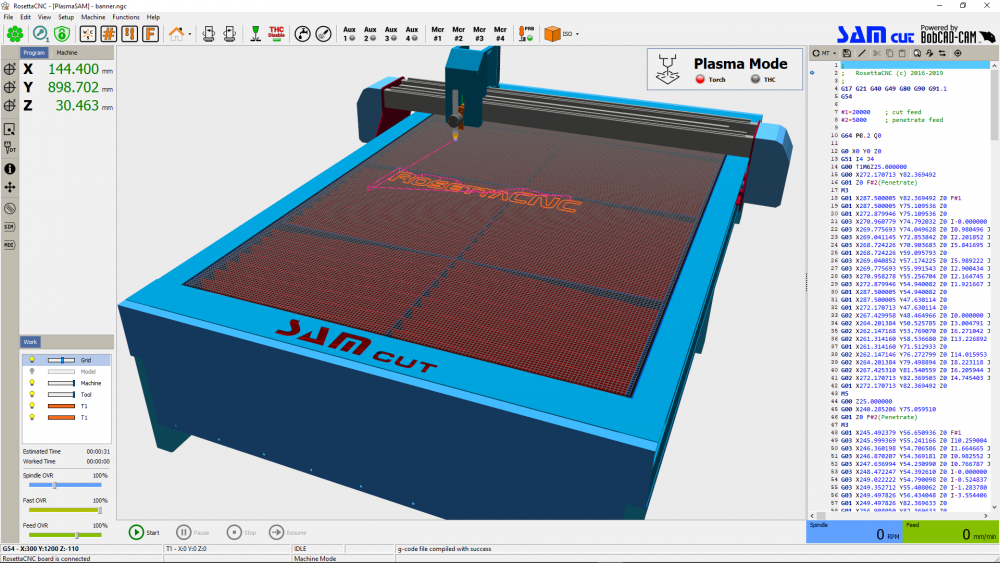

The Control Software is a powerful UI Environment, for Windows OS used to manage and program the Board.

Through the Control Software, you can load and create the G-Code programs, configure and monitor the Board, and simulate/analyze a program with virtual machines before running it with the Board.

1.3 The Plugin Industry 4.0

To meet the requirements of Industry 4.0 a dedicated plugin for RosettaCNC has been developed.

With this plugin your CNC can:

- Communicate with other systems using the OPC-UA secure industrial protocol.

- Send files to your CNC using FTP or the secure FTPES.

- Send alarm notifications using emails.

- Record CNC events on a CSV file.

Using the OPC-UA protocol almost all CNC data can be read from a standard OPC-UA client.

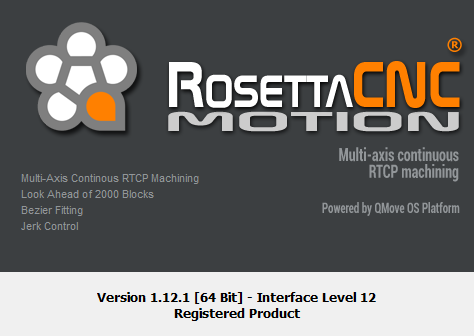

2. Control Software

| Command | Spindle OVR | Fast OVR | Feed OVR | Feed OVR Custom 1 | Feed OVR Custom 2 |

|---|---|---|---|---|---|

M48 | ON | ON | ON | off | off |

M49 | off | off | off | off | off |

M50 | unchanged | ON | ON | off | off |

M50 P0 | unchanged | off | off | off | off |

M50 P1 | unchanged | ON | ON | off | off |

M50 P2 | unchanged | off | off | ON | off |

M50 P3 | unchanged | off | off | off | ON |

M51 | ON | unchanged | unchanged | unchanged | unchanged |

M51 P0 | off | unchanged | unchanged | unchanged | unchanged |

M51 P1 | ON | unchanged | unchanged | unchanged | unchanged |

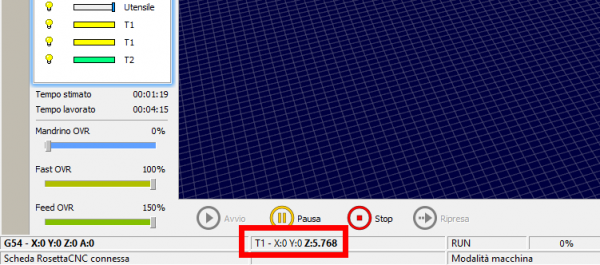

3. CNC Board States

The active CNC Board state is always visible in the status bar of the Control Software as marked in the red rectangle.

The CNC Board can be in one of the following internal states:

- INIT

- Waiting for internal state initialization.

- The CNC Board is in the initialization phase of the main modules.

- INIT FIELDBUS

- Waiting for the EtherCAT Fieldbus to be initialized (all slaves in OPERATIONAL).

- The CNC Board is in the initialization phase and waiting for the EtherCAT Fieldbus to be initialized.

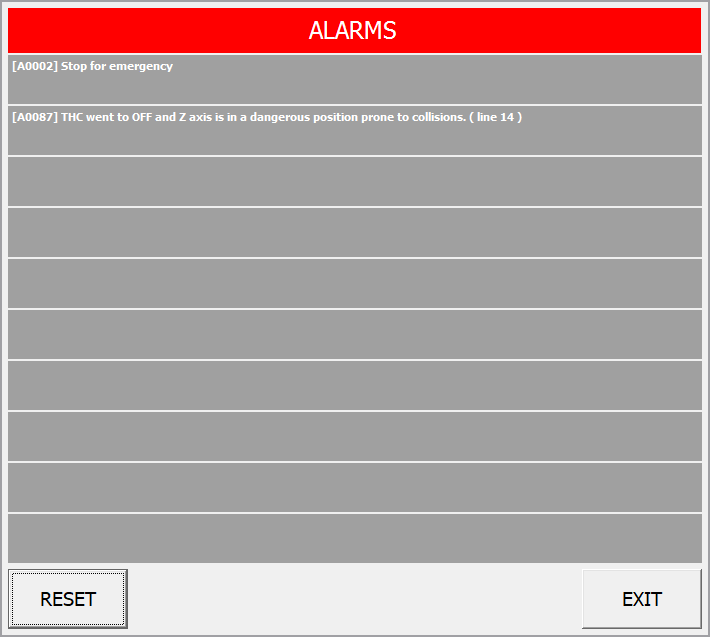

- ALARM

- When the CNC Board catches an alarm condition stops any activity and enters in

ALARMstate. - In this case:

- The running G-Code Program\Macro\MDI is stopped in the current block.

- Any other activity (JOG, Homing, Scan 3D, etc) is stopped immediately.

- The axes' movements are stopped without deceleration ramps.

- The Homing references, if CNC doesn't use absolute encoders with EtherCAT configuration, are invalidated and back in the red state.

- All AUX outputs are automatically placed in the OFF state.

- This state remains till all alarms cause are removed and the alarms list is cleared.

- To clear alarms list:

- Activate the user input with assigned the feature

Reset Alamars. - Press

CTRL+F11in the Control Software. - Double click on the alarm message to who Alarms panel and click the Reset button.

- From the main menu

- IDLE

- The CNC Board is in the IDLE state ready to execute a command.

- HOMING

- The CNC Board is in the HOMING state and one or more axes are doing the homing research.

- JOG

- The CNC Board is in the JOG state and one or more axes are doing a Jog movement.

- RUN

- The CNC Board is in the RUN state and a G-Code Program/Macro/MDI is executing.

- PAUSE

- The CNC Board is in the PAUSE state and a G-Code Program/Macro/MDI is in pause.

- LIMIT

- The CNC Board is in the LIMIT state because one or more LIMIT digital input is active.

- SCAN3D

- The CNC Board is in the SCAN3D state.

- SAFETY IDLE

- Jog is allowed with reduced speed.

- CNC is in SAFETY state and JOG movements are allowed with reduced speed.

- CHANGE TOOL

- CNC Board is performing a tool changing procedure.

- SAFETY

- All axes are disabled, the main power can be switched off without causing an alarm.

- WAIT MAIN POWER

- The CNC Board enters in this state when the

- RETRACT

- The CNC Board enters into this state depending on the

Withdraw/Retract Tool at Stop Settingsparameters defined in theBoard Settings(See Description). - Withdraw/Retract Tool feature permits to define what CNC has to do when a STOP action is requested to CNC (eg: STOP user input goes active).

- It permits to extract the tool from the stock of a desired distance and velocity.

- After Withdraw/Retract Tool action CNC will execute the STOP action and will enter in

IDLEstate.

TAKE CARE: If the CNC has not searched for the reference point (homing), the CNC will not carry out the Withdraw/Retract Tool procedure.

Control Software has two extra states depending on the connection state with the CNC Board or the state of the Simulator:

- DISCONNECTED

- CNC is not connected with the Control Software.

- SIMULATOR

- The Control software is in Simulator state.

- To enter in the Simulator state is not necessary to be connected with a CNC Board.

- If the Control Software is connected with a CNC Board to enter in Simulator state the board must be in IDLE state.

4. Program Settings

Program Settings panel permits to sets the Control Software behavior.

The following images represent the settings captured from the default machine just as after a clean installation and are only for samples.

4.1 General

4.1.0.1 Interface Settings

- Units Mode

- Permits to define the Units Mode used in the Control Software UI between

Metric (mm)andImperial (in). - It ONLY sets the measures representation in the UI so, in the G-Code, the Units Mode can be defined with a

G20orG21and can be different than UI. - During the G-Code Program/Macro/MDI execution,

G20andG21commands can be freely mixed but UI representation will be fixed to this setting. - All fields and settings of the UI are affected by the Units Mode except for Board Settings which are always expressed in the Metric System.

4.1.0.2 General Settings

- Enable Automatic Update Check

- If enabled actives automatic check, at Control Software start and every 3 minutes, of online updates.

- If an update is available a blinking advice message will be shown in Control Software Status Bar.

- If disabled you can manually check if an update is available with the main menu

Help → Check for Updates. - Update Manager checks for online updates regarding only the current version, eg: 1.9.x search only for 1.9 branches.

- The update Check feature can be locked, to the end-user, using Access Levels settings.

- PS: During the Update phase, if Windows UWF Status is found Enabled, the update procedure will be stopped because is not possible to update permanently files in a UWF protected disk.

- Enable Automatic Connection with the CNC Board

- If enabled it actives automatic connection with CNC Board at Control Software starts.

- Enable Overwrite of CNC Board Settings at Connection

- When Control Software opens a connection with CNC Board it checks if Board Settings in CNC Board are the same as Board Settings stored on Control Software.

- If settings are different, and this option is enabled, the Control Software automatically sent Board settings on Control Software to CNC Board.

- If this option is disabled, a prompt user dialog will show the state and will ask the end-user to Download Control Software Board Settings to CNC Board or Upload CNC Board settings to Control Software.

- This feature is very useful when the same CNC Board is used in a CNC machine that uses more than one configuration, such as a 3-Axis vertical spindle or a 4-Axis horizontal spindle.

- Enable the Opening of the Default Folder on Request of the “Open File…” Dialog

- If enabled it permits to define the default folder open on Request of the main menu

File → Open File…dialog or pressing theF12key. - Special Windows folder shortcuts can be used here (for eg.

%APPDATA%, to reach the user application data folder).

- Enable Checking if the Loaded G-Code File Content is Modified by Another Program

- If enabled it permits to define how to update the loaded G-Code file when a new version is available.

- This happens, for eg., when a user asks CAM to create a new G-Code output file or when the G-Code file is modified by the user with a text editor.

- Four different actions could be chosen:

- Ask user what to do if the system is ready

- When the loaded G-Code program changes externally, and the CNC is in IDLE, a prompt dialog asks the user what to do.

- Ask user what to do when the system will be ready

- When the loaded G-Code program changes externally, and the CNC is not in IDLE the check system waits for CNC IDLE, then a prompt dialog asks the user what to do.

- Load automatically newer file content if the system is ready

- When the loaded G-Code program changes externally, and the CNC is in IDLE, the G-Code program will be automatically reloaded.

- Load automatically newer file content when the system will be ready

- When the loaded G-Code program changes externally, and the CNC is not in IDLE the check system waits for CNC IDLE, then the G-Code program will be automatically reloaded.

4.2 Controls

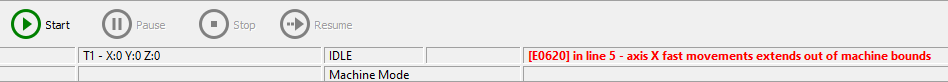

4.2.0.1 CNC Board Control Buttons

- Start Visible

- Defines if the Start button will be visible, or not, in the CNC Board Control Bar.

- Pause Visible

- Defines if the Pause button will be visible, or not, in the CNC Board Control Bar.

- Stop Visible

- Defines if the Stop button will be visible, or not, in the CNC Board Control Bar.

- Resume Visible

- Defines if the Resume button will be visible, or not, in the CNC Board Control Bar.

4.2.0.2 Jog Controls Panel Settings

- Enable Jog With Keyboard

- Enables the Jog control with the keyboard.

- With the Keyboard is possible to control X-Axis (

Left/Rightkeys), Y-Axis (Up/Downkeys), and Z-Axis (Page Up/Page Downkeys). - To do Jog with the keyboard the Jog Controls panel axis control must be visible and focused.

- To focus it click the mouse in the near zone or press the

F1key one or two times till the blue focus rectangle is shown.

- Auto Disable Jog Space Mode

- Enables the auto-disable of Jog Space Mode.

- When Jog movements are made with the Jog Controls panel and the

Jog Spacefield is checked, withAuto Disable Jog Space Modeactive, at end of the movement theJog Spacefield will be automatically disabled.

- Fixed Distance with CTRL + Fast Click

- Defines the fixed distance used when with the

CTLRkey pressed a fast key/left-mouse click is done in the desired axis movement. - When the

CTRLkey is pressed a fast click, below 500 ms of duration, moves the selected axis of programmed distance. - When the

CTRLkey is pressed a long long click, over 500 ms of duration, executes a normal Jog axis movement but with an initial delay of 500 ms required to detect if in the fixed distance mode.

4.2.0.3 Dynamic Offsets Panel Settings

Dynamic Offsets permit to add positive/negative offset to X/Y/Z-Axis during CNC working using the related floating panel.

A change of Dynamic Offsets is possible only with CNC in RUN State and in a range of +3/-3mm.

Don't use Dynamic Offsets during RTCP enabled movements (G43.4 or G43.7).

- Enable Dynamic Offset X

- Enables the Dynamic Offset feature for X-Axis.

- Enable Dynamic Offset Y

- Enables the Dynamic Offset feature for Y-Axis.

- Enable Dynamic Offset Z

- Enables the Dynamic Offset feature for Z-Axis.

- Dynamic Offsets Step

- Defines the minimum step (+ or -) of Dynamic Offsets value change.

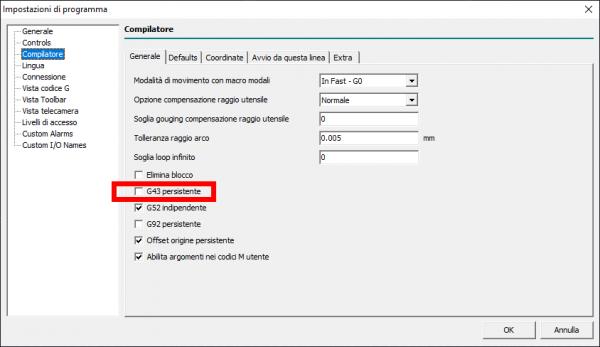

4.3 Compiler

4.3.1 General

- Modal Macro Motion Mode

- Define the default motion mode used to perform the movements between two custom macro repetitions (Look at Modal Macro calls):

- In Fast - G0

- A fast movement with the

G0command will be performed.

- In Feed - G1

- A feed movement with the

G1command will be performed.

- In the G-Code Program/Macro/MDI, with the

G10 L100 P5800 V<value>command is possible to specify a different value from the default (#5800 = 0 → G0;#5800 = 1 → G1). - At the start of the G-Code Program/Macro/MDI, the default motion mode value will be always restored.

- Cutter Compensation Option

- Defines how the CNC Board will manage the Tool Cutter Compensation enabled with

G41/G41.1andG42/G42.1commands. - The available options are:

- NIST

- The default NIST mode.

- Easy Lead-In

- Delays the first movement of the entry move until the following line or arc is specified.

- When the second entry motion is specified it performs the entry move to a position tangent to the beginning of the second line or arc.

- This option works well with some CADs such as Fusion360 indeed no gouging errors are generated.

- Normal

- It is the only option that can handle concave corners and concave arcs.

- PS: For more info look at Tool Compensation Entry Options.

- Cutter Compensation Gouging Threshold

- Defines the cutter compensation gouging threshold applied to

G41/G41.1orG42/G42.1commands whenCutter Compensation Optionis set toNormal.

- Arc Radius Tolerance

- Defines the maximum accepted difference of the distance between the start point and the center of an arc and that between the end-point and the center of the arc before generating a compilation error.

- The value should be also equal to or higher than the greatest axes quantum movement (Axis Quantum = CNC Board axis

Measure / Pulses).

- Infinite Loop Threshold

- Defines how to manage a possible infinite loop in

WHILEcommands. - When the value is set to 0 means: Continue till the

WHILEexpression is satisfied or the user press theESCkey to abort the current compilation. - When the value is set > 1 means: Continue till the

WHILEexpression is satisfied or the user press theESCkey to abort the current compilation or then-valueloops are reached.

- Esample of an infinite loop:

- In this case the coder missed to increment #1 value (eg:

#1=[#1+1]) so the loop with Infinite Loop Threshold = 0 will continue to infinite. - For example with Infinite Loop Threshold = 10000, after 10000 loops the compiler will notice an error and stop compiling automatically.

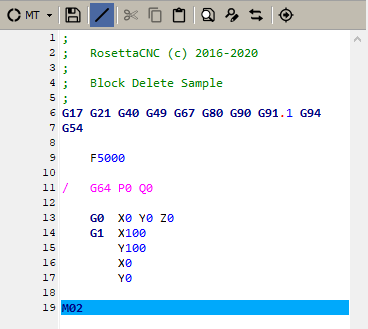

- Block Delete

- Enables Block Delete management.

- Block delete is used in a program by placing a forward slash (

/) at the beginning of the line. - It is a useful function that allows the operator to skip the blocks within the program.

- When the Block Delete option is enabled, and G-Code Editor Block Delete icon is active, all G-Code lines with

/will be disabled and not executed. - The G-Code located to the right of an enabled Block Delete is still subject to syntactic check even if the code execution will be skipped:

- G43 Persistent

- Defines if

G43compensation is persistent in CNC Board at end of a G-Code Program/Macro/MDI execution.

- G52 Independent

- Defines if

G52is independent between changes of active WCS in a G-Code Program/Macro/MDI execution.

- G92 Persistent

- Defines if

G92offsets are persistent in the CNC Board at end of a G-Code Program/Macro/MDI execution.

- Origin Offset Persistent

- Defines if the changing of the selected World Coordinate System (WCS) made in the G-Code Program/Macro/MDI is kept at end of code execution:

- Checked

- At the start of the program execution, the current active WCS is used.

- At the end of the program execution, any changing of selected WCS with the

G54/G55/G56/G57/G58/G59.1/G59.2/G59.3commands will be kept. - In the case of the program stop, the current selected WCS is kept.

- Unchecked

- At the start of the program execution, the current active WCS is used.

- At the end of the program execution, any changing of selected WCS with the

G54/G55/G56/G57/G58/G59.1/G59.2/G59.3commands will be lost and WCS 1 (G54) is applied. - In the case of the program stop, the current selected WCS is kept.

The changes to any WCS origin offset values made with the G10 L2 Pp Xx Yy Zz Aa Bb Cc command are not affected by this parameter.

- Enable User M Code Arguments

- Define if the user-defined M macros will accept arguments, eg:

M201 A10 J-1.3.

- Enable the Creation of Simulator Data

- Defines if the creation of Simulator Data is enabled.

- Disabling Simulator Data will improve G-Code program compilation time and will reduce the memory used by the PC.

- In the 32-bit version of the control software, when the estimated execution time of the G-code exceeds 5 hours, the simulator data is automatically disabled.

4.3.2 Macro

- User Macro Path Mode

- Two types of macros are available in the G-Code language: Machine Macros and User Macros.

- The Machine Macros are stored in the folder

%APPDATA%\RosettaCNC-1-\<machine>\macros. - To quickly reach the actual Machine Macros folder, you can use the “

File → Open Macro Folder” menu. - Machine Macros can be used to create new

G&Mcommands, provide well-defined CNC functions such as tool change, or subroutines that can be called up by number/name using theM98/G65/G66/CALLcommands. - User Macros can be ONLY used to create subprogram callables by name.

- User Macro Path is used ONLY if the subprogram is called with the prefix

/, eg:G65 P“/square_pocket.ngc” W100. H100. Z-40. R-5. T2. - The User Macro Path Mode allows this by choosing from the following options:

- Disabled

- The User Macro feature is disabled.

- GCode File Path

- The User Macros are searched in the same path as the currently opened G-Code Program.

- User Defined Path

- The User Macros are searched in the below-defined path.

- Path

- Defines the path where the User Macros are stored when the User Defined Path option was chosen.

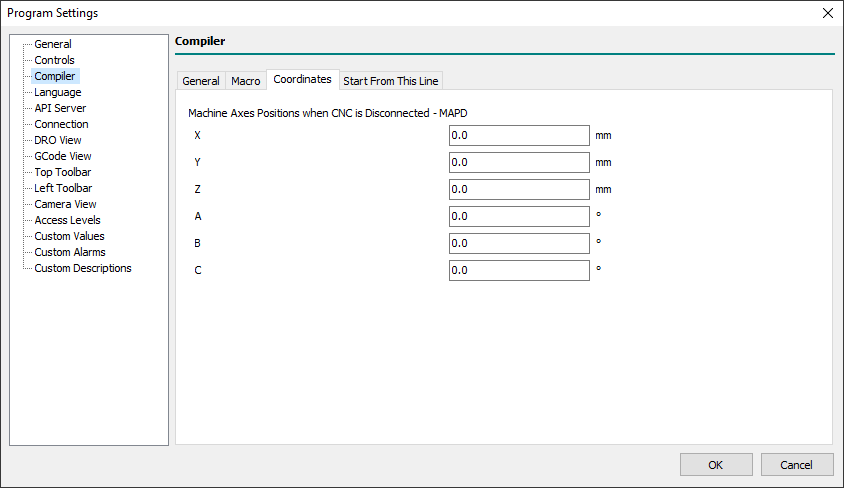

4.3.3 Coordinates

- Machine Axes Positions when CNC is Disconnected - MAPD

- Defines the machine axes positions used in Control software when not connected with a CNC Board.

- Typically these values are used how axes start points during G-Code simulation with internal software Simulator and without a CNC Board connected.

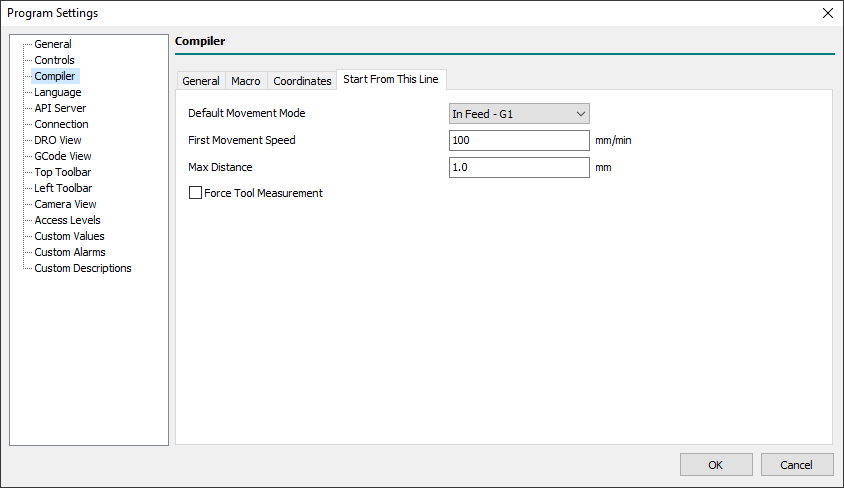

4.3.4 Start From This Line

The System Macro restart.ngc manages all the activities necessary to START machining from a specific program line or to RESUME machining stopped with a STOP command from the last executed line or from one of your choice.

However, when the macro is not available, a series of minimal operations are performed.

The following parameters allow you to configure these operations.

- Default Movement Mode

- Defines how the CNC make the default movements to start Start/Restart from a line from:

- In Feed - G1:

default movements will use theG1command (feed movement). - In Fast - G0:

default movements will use theG0command (fast movement). - Handheld by the PLC:

default movements are managed by PLC internal strategy.

- First Movement Speed

- Defines the default movement speed when Default Movement Mode is set to In Feed - G1.

- Max Distance

- Defines the maximum accepted distance between the actual CNC position and the first CNC target position described in the G code.

- If the distance is greater than Maximum Distance, an error message will be displayed in the dialog box and no movement will be made.

- Force Tool Measurement

- If enabled, if the currently loaded tool is different from the required tool, the Tool Change procedure will be forced otherwise an error message will signal the case and no movement will be performed.

PS: This is a very poor way to manage a START/RESTART from a line. The use of the restart.ngc macro is the right way to get better management of that.

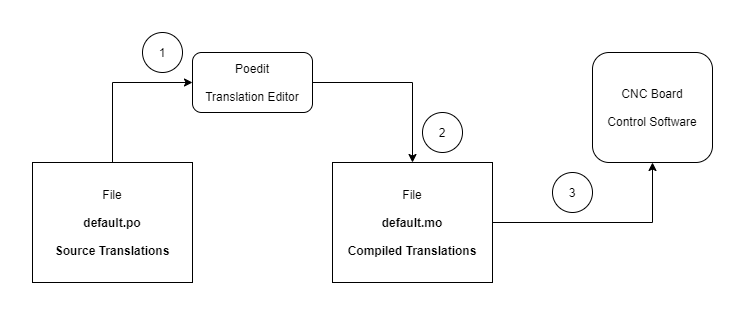

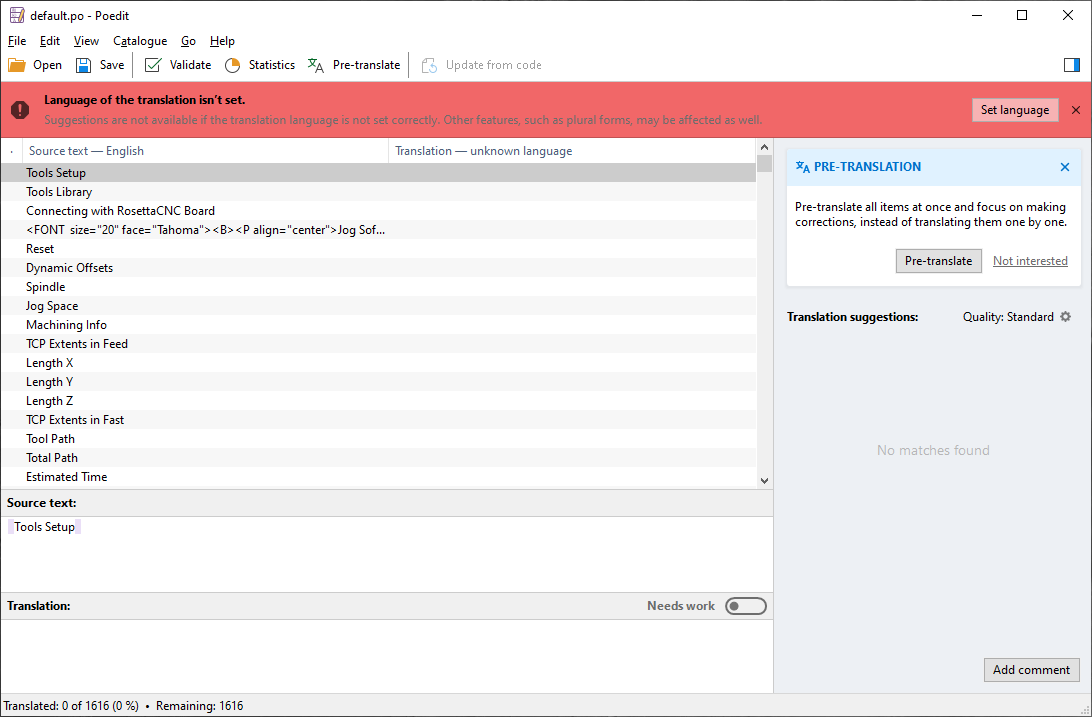

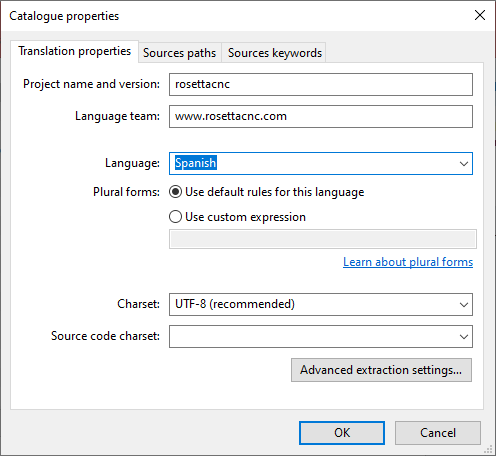

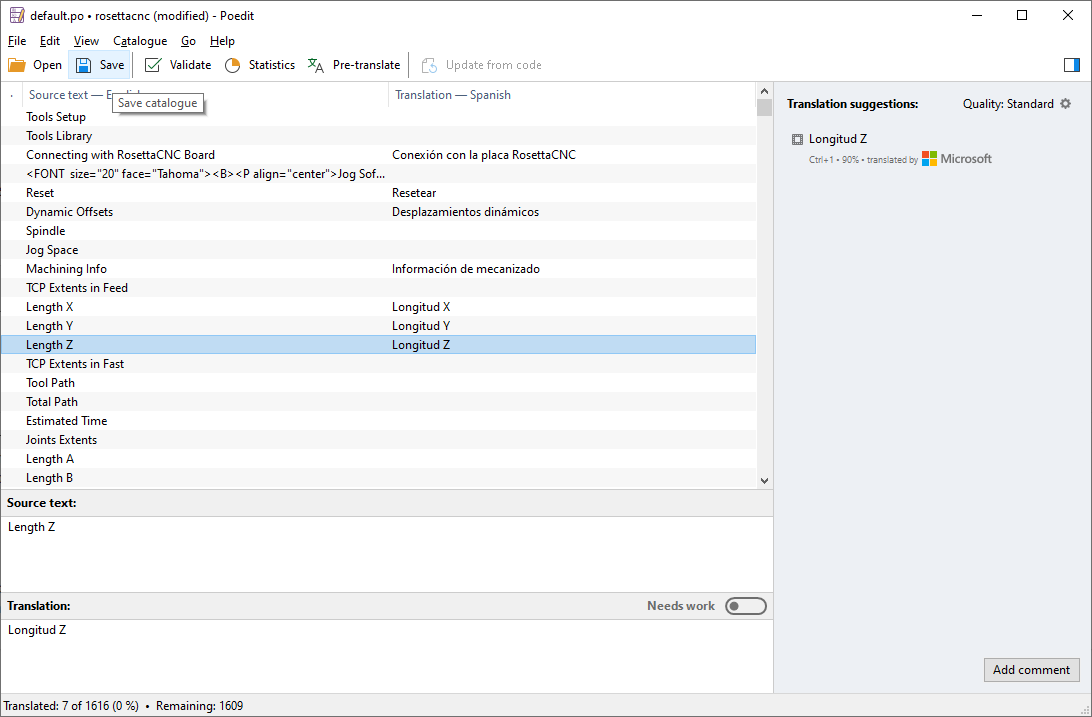

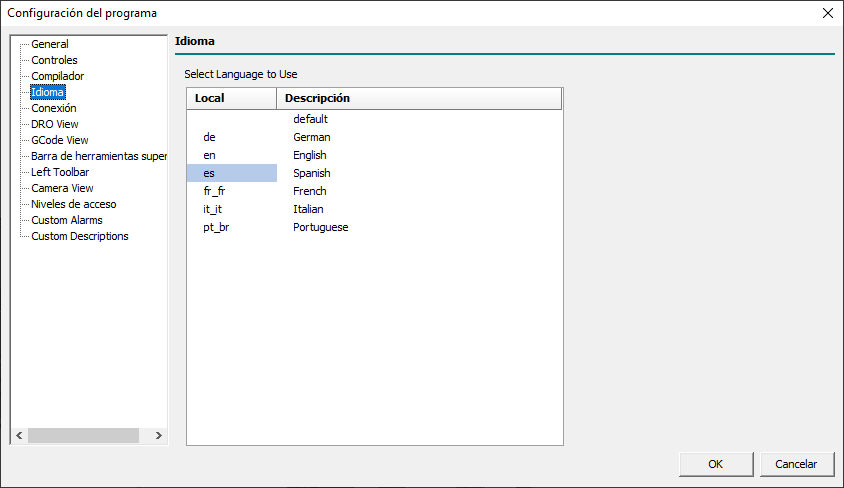

4.4 Language

- Select Language to Use

- Permits to define the UI language to use choosing from available languages.

- Any change of current language requires a Control Software re-start to be fully applied.

PS: The Default item means “Use current computer default language, if present in the list, otherwise use the English language”.

4.5 API Server

Through the API Server, the Control Software exports a part of its API which can be used with external client applications.

The API server is a TCP/IP Server listening on localhost with a communication protocol based on JSON Request/Response packets.

The API Server, if enabled, will be activated automatically when the Control Software is started.

If, when starting the Control Software, the API Server Listening Port is found to be already in use, the following dialog will be displayed:

- Enable API Server

- Enabled the Control Software API Server.

- Listen Port

- Localhost Listening Port of the API Server.

- It can be any localhost port not already used in the range 0 to 65535.

- Enable “Cmd” Commands Group

- Enable the API Server “Cmd” commands group.

- Enable “Set” Commands Group

- Enable the API Server “Set” commands group.

- Enable “TLS” (Transport Layer Security)

- NOT YET IMPLEMENTED!

PS: The changes to the API Server will take effect the next time the Software Control is started.

4.6 Connection

4.6.0.1 Network Adapters [IPv4]

This panel displays all the Network Adapters for the Internet Protocol version 4 that can be reached by the Control Software.

For each adapter in the list, the IP address, the NET MASK and the NET NAME are available.

- Update List

- Updates the list of Network Adapters.

- This is necessary if you change the Network configuration, eg: enabling a new LAN/WIFI connection.

4.6.0.2 CNC Board Connection Settings

- IP

- Defines the IP of the CNC Board to connect with.

4.6.0.3 Advanced Settings

- Change IP

- Permits to discovery and change the IP Settings of the CNC Boards connected in the Network.

- For more information, see the “How To: Change Board IP” page.

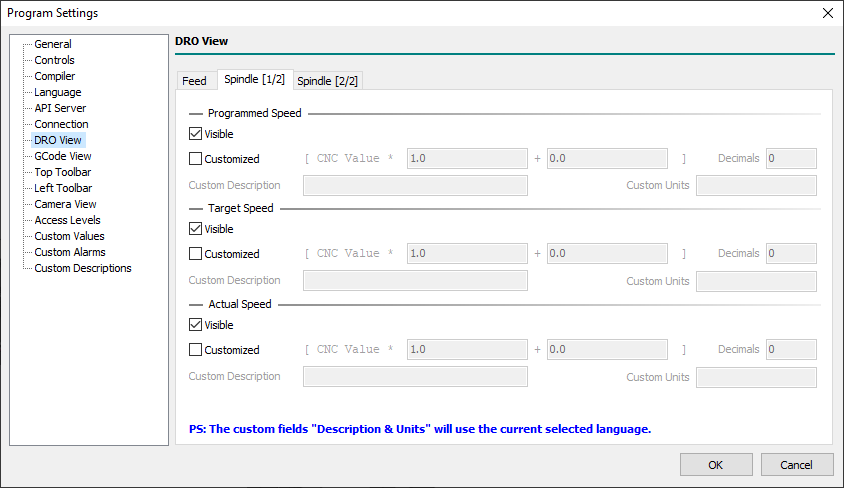

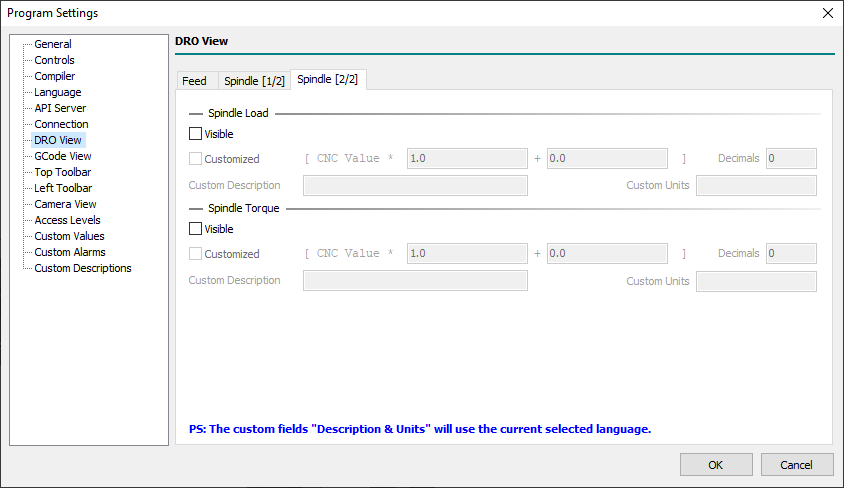

4.7 DRO View

4.7.1 Feed

4.7.2 Spindle [1/2]

4.7.3 Spindle [2/2]

4.8 GCode View

4.8.1 General

- Grid Size

- Defines the size of the Grid used to represent the XY-Axis area in the machine coordinates.

- Grid Z Position

- Defines the Z machine coordinate where the Grid will be placed.

- Is usual to place this value at the same Z-Axis Min Limit value.

- Initial View

- Defines the initial 3D view mode used as default when the Control Software is executed.

- The graphical engine will automatically fit the 3D scene objects to be all shown in the display.

- Choose one of the following values:

- Front

- The initial view will be on the front of the CNC.

- Back

- The initial view will be on the back of the CNC.

- Top

- The initial view will be at the top of the CNC.

- Bottom

- The initial view will be at the bottom of the CNC.

- Left

- The initial view will be on the left of the CNC.

- Right

- The initial view will be on the right of the CNC.

- ISO 1..9

- The initial view will be one of the ISO perspective modes.

- Custom View 1..4

- The initial view will be one of the ISO perspective custom modes.

- Scene AntiAliasing

- Defines the strength of Antialiasing filter applied by the graphical engine to 3D scene:

- Default

- Antialiasing disabled (will take the first available pixel format).

- None

- Antialiasing disabled (will take the first available pixel format).

- (MSAA): 2x

- Multisampled Antialiasing (MSAA): 2x.

- (MSAA): 2xHQ

- Multisample Antialiasing (MSAA): 2x High Quality.

- (MSAA): 4x

- Multisampled Antialiasing (MSAA): 4x.

- (MSAA): 4xHQ

- Multisampled Antialiasing (MSAA): 4x High Quality.

- (MSAA): 6x

- Multisampled Antialiasing (MSAA): 6x.

- (MSAA): 8x

- Multisampled Antialiasing (MSAA): 8x.

- (MSAA): 16x

- Multisampled Antialiasing (MSAA): 16x.

- (CSAA): 8x

- Coverage Sampled Antialiasing (CSAA): 8x.

- (CSAA): 8xHQ

- Coverage Sampled Antialiasing (CSAA): 8x High Quality.

- (CSAA): 16x

- Coverage Sampled Antialiasing (CSAA): 16x.

- (CSAA): 16xHQ

- Coverage Sampled Antialiasing (CSAA): 16x High Quality.

Default and None are similar but not the same.

Default does not touch the settings related to sample buffers of the OpenGL context from what defined in GPU Windows Settings.

None disables WGL_SAMPLE_BUFFERS_ARB and therefore the Anti-Aliasing management completely.

MSAA stays for Multi Sampled Antialiasing.

CSAA stays for Coverage Sampled Antialiasing.

Coverage Sampled Antialiasing (CSAA) is supported by NVIDIA cards (CSAA Tutorial)

- Scene Nuance Mode

- Xxx…

- Scan Points Colors

- Xxx…

- Scan Mesh Colors

- Xxx…

- Hide Tool

- Xxx…

- Path Line Size

- Xxx…

- Tool Tip Size

- Xxx…

4.8.1.1 Tool Path Preview Settings

- Resolution

- Xxx…

- Set Number of Points per Block

- Xxx…

- Points per Block

- Xxx…

4.8.1.2 Theme Management

- Load

- Permits to load a saved theme from a file.

- Save

- Permits to save the current theme in a file.

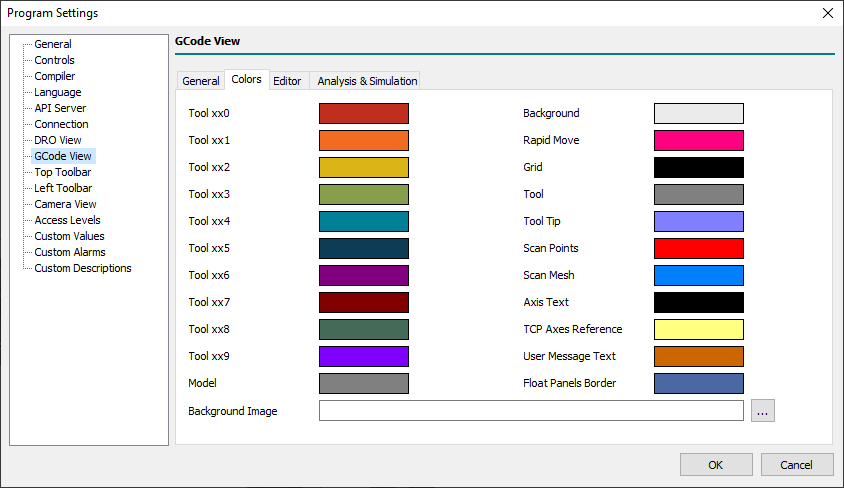

4.8.2 Colors

- Tool xx0..xx9

- Defines the colors assigned to Tools.

- The color assigned to the Tool depends on the last Tool digit number.

- Eg: Tool 1, 11, 21, .. share the same Tool color as 2, 22, 92, and so on.

- Model

- Defines the color of the G-Code program Model geometry.

- The G-Code program model is an STL file with the same G-Code program name, but extension STL, loaded when a G-Code program is loaded.

- Background

- Defines the 3D scene background color.

- This color is used when in the machine

customizepath is not available thebackground.pngbackground image. - If in machine

customizepath is available thebackground.pngimage the system will use the image instead of background color.

- Rapid Move

- Defines the color for toolpath G00 (rapid) movements.

- Grid

- Defines the color of the working area Grid.

- Tool

- Defines the color of the Tool Body.

- Tool Tip

- Defines the color of the Tool Tip Body.

- Scan Points

- Defines the color of Scan Points during Scanning 3D/Scanning Surface features.

- Scan Mesh

- Defines the

- Axis Text

- Defines the color of the Axis text in MCS origin.

- User Message Text

- Define the color of the User Message for the M109 command.

- Float Panels Border

- Defines the Float Panels border color for Jog/MDI/etc.

4.8.3 Editor

4.8.3.1 Font Settings

- Name

- Xxx…

- Size

- Xxx…

- Tab Size

- Xxx…

4.8.3.2 Color Settings Settings

- Color

- Xxx…

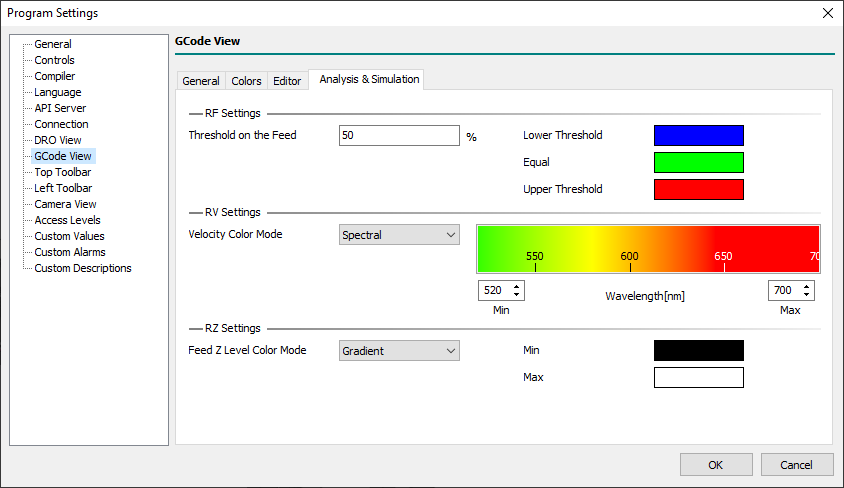

4.8.4 Analysis & Simulation

4.8.4.1 RF Settings

- Threshold on the Feed

- Xxx…

- Lower Threshold

- Xxx…

- Equal

- Xxx…

- Upper Threshold

- Xxx…

4.8.4.2 RV Settings

- Velocity Color Mode

- Xxx…

4.8.4.2.1 Spectral

- Min

- Xxx…

- Max

- Xxx…

4.8.4.2.2 Gradient

- Min

- Xxx…

- Max

- Xxx…

4.8.4.3 RZ Settings

- Feed Z Level Color Mode

- Xxx…

4.8.4.3.1 Spectral

- Min

- Xxx…

- Max

- Xxx…

4.8.4.3.2 Gradient

- Min

- Xxx…

- Max

- Xxx…

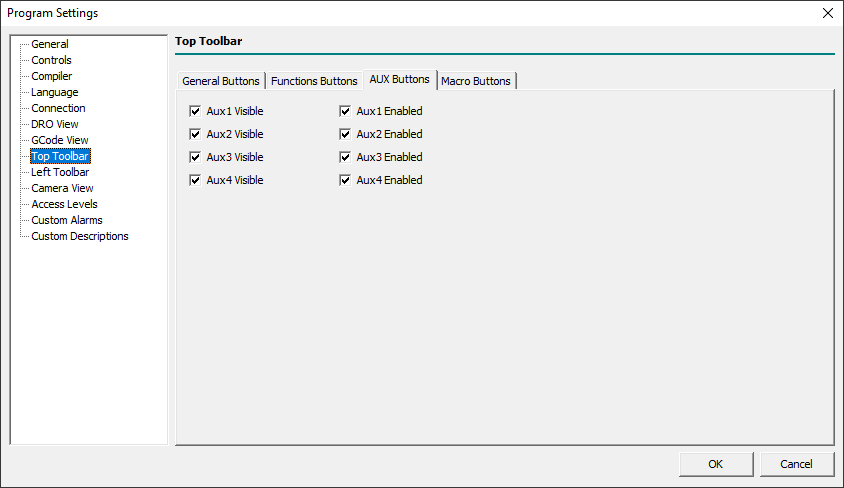

4.9 Top Toolbar View

Through this panel and related sheets, it is possible to set the visibility of buttons in the top toolbar.

4.9.1 General Buttons

4.9.2 AUX Buttons

4.9.3 Macro Buttons

4.10 Left Toolbar View

Through this panel, it is possible to set the visibility of some button in the left toolbar, also know as Machine Toolbar.

4.10.1 General Buttons

- Show Jog Controls Visible

- Defines the visibility of the left toolbar

Show Jog Controlsbutton. - When the button is not visible the

Jog Controlspanel can be yet shown/hidden pressing theF1key or using the related main menu item. - When the UI central area view is not in

Main View, showing or hiding theJog Controlspanel will automatically switch the view toMain View.

- Show MDI Commands Visible

- Defines the visibility of the left toolbar

Show MDI Commandsbutton. - When the button is not visible the

MDI Commandspanel can be yet shown/hidden pressing theF4key or using the related main menu item. - When the UI central area view is not in

Main View, showing or hiding theMDI Controlspanel will automatically switch the view toMain View.

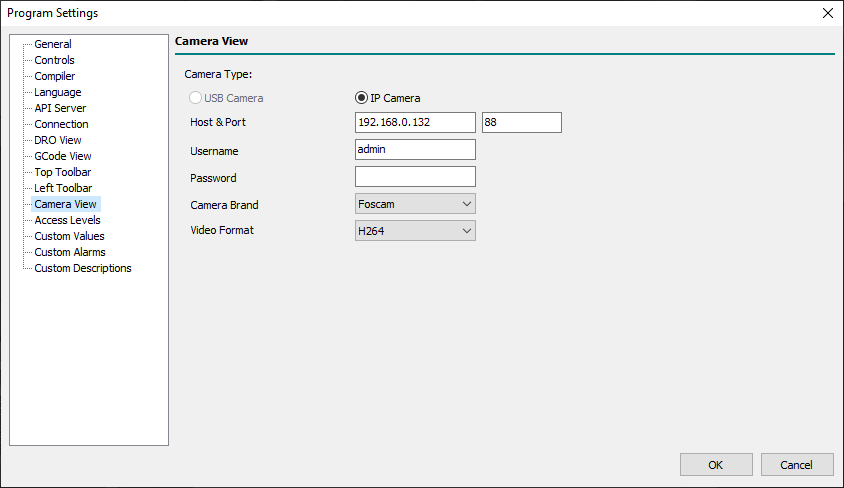

4.11 Camera View

- Camera Type

- Defines the type of connected camera between “USB Camera” and “IP Camera”.

- At the moment ONLY IP cameras are supported.

- USB Camera

- Sets the Vision Engine to work with a USB Camera.

- IP Camera

- Sets the Vision Engine to work with an IP Camera.

- Host & Port

- Defines the Host & Port of the IP Camera.

- Username

- Defines the Username necessary to connect to the IP Camera internal server.

- Password

- Defines the Password necessary to connect to the IP Camera internal server.

- Camera Brand

- Defines the brand of IP Camera from one of supported brands:

- Undefined

- Foscam

- Panasonic

- Aviosys

- Smartec

- ACTi

- ArcVision

- Axis

- DLink

- Beward

- Genius

- Planet

- Samsung

- Trendnet

- Vivotek

- Video Format

- The Vision Engine support the following video formats:

- MJPEG

- H264

4.12 Access Levels

Through this panel, it is possible to restrict write access or disable access to some settings menus by binding everything to a password.

The system allows three access levels: L1, L2, and L3.

Level 1 is linked to the operations carried out by the machine operator.

This level does not have an associated password as it is active by default when the Control Software is started.

Level 2 could be associated with the maintenance technician of the machine who periodically may need to intervene in some aspects of the same.

Level 3 is usually the level associated with the manufacturer who is the only one who can intervene on delicate parts such as axis settings, or the firmware and software update functions.

- Access Levels Table

- The table shows the functions of the Control Software that can be bound by an access level.

- The orange DOT symbol indicates to which access level every single function is associated.

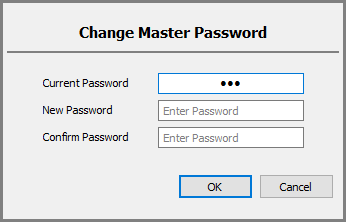

- Set Master Password

- In order to activate the system of access levels, the manufacturer of the machine must introduce a Master Key which is necessary so that it is possible to associate the functions to the various levels.

- By default, after installation, the master access key is not set and the functions are available to anyone as the access level management is not configured.

- The master key must be brought back and kept in order to be able to configure the access levels at any time.

- If the master password has never been entered, a double confirmation will be requested before accepting it:

- If a master password has already been entered and you want to change it, you must first enter the old password followed by the double-entry of the new one:

- A new password consisting of an empty string means that you want to disable the level access system.

- Password L2

- Defines the password for access level L2.

- The password can be numeric or alphanumeric.

- The password must be different from the master password or other level passwords.

- Password L3

- Defines the password for access level L3.

- The password can be numeric or alphanumeric.

- The password must be different from the master password or other level passwords.

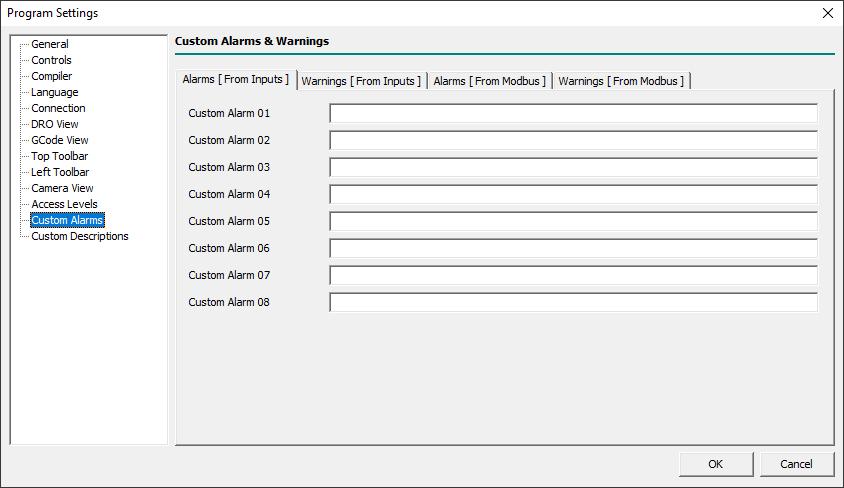

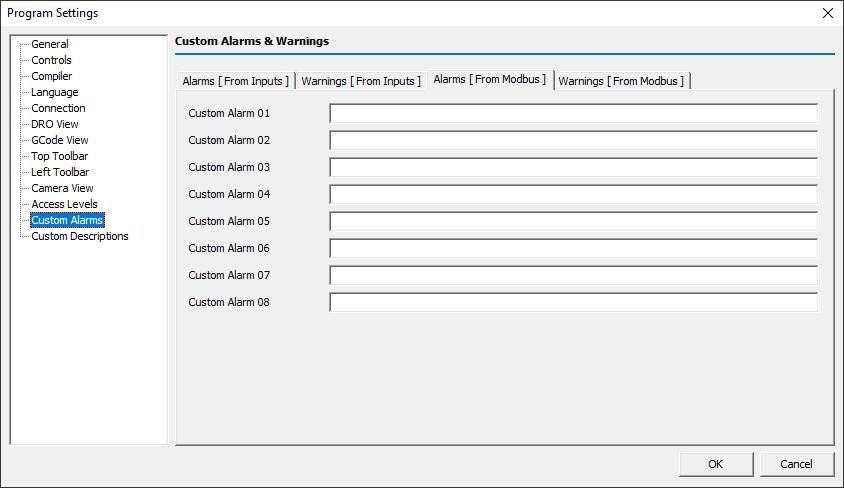

4.13 Custom Alarms

4.13.1 Alarms [ From Inputs ]

4.13.2 Warnings [ From Inputs ]

4.13.3 Alarms [ From Modbus ]

4.13.4 Warnings [ From Modbus ]

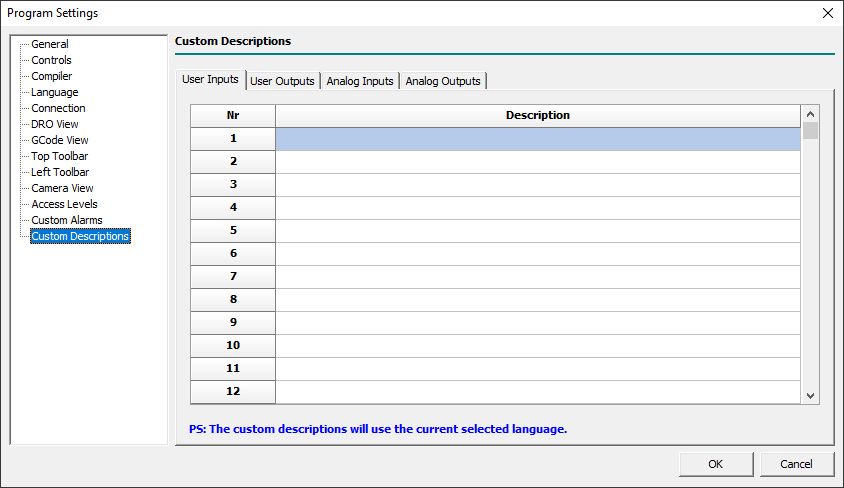

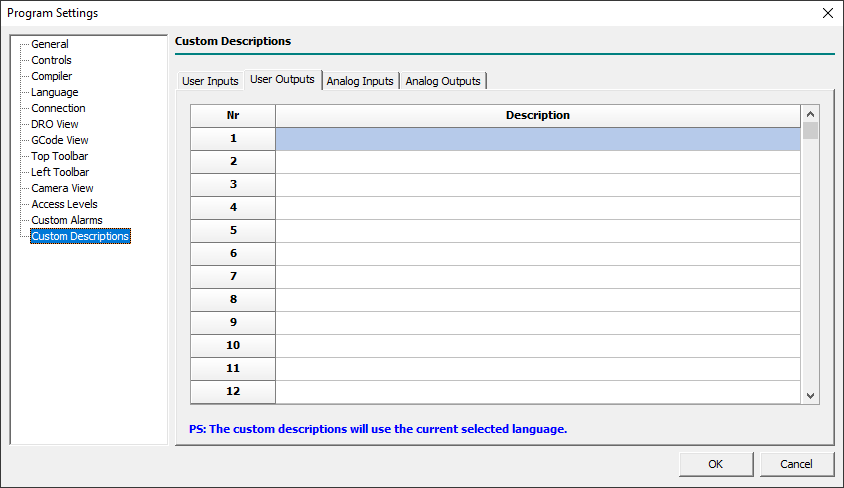

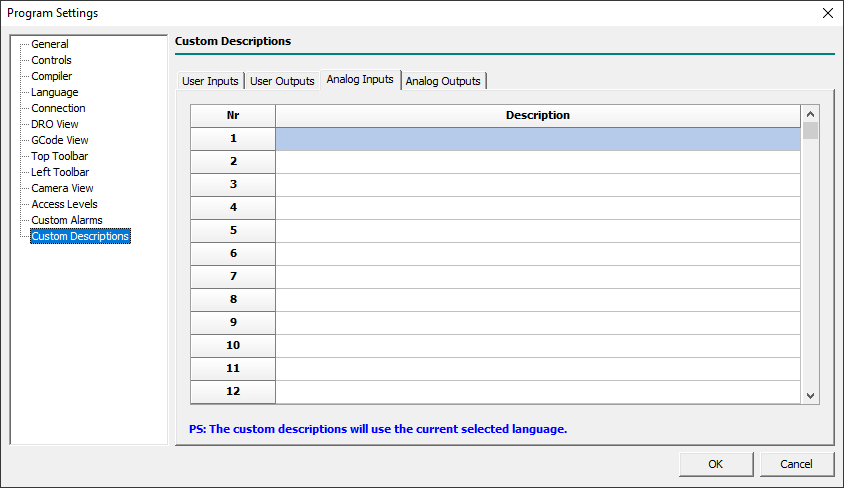

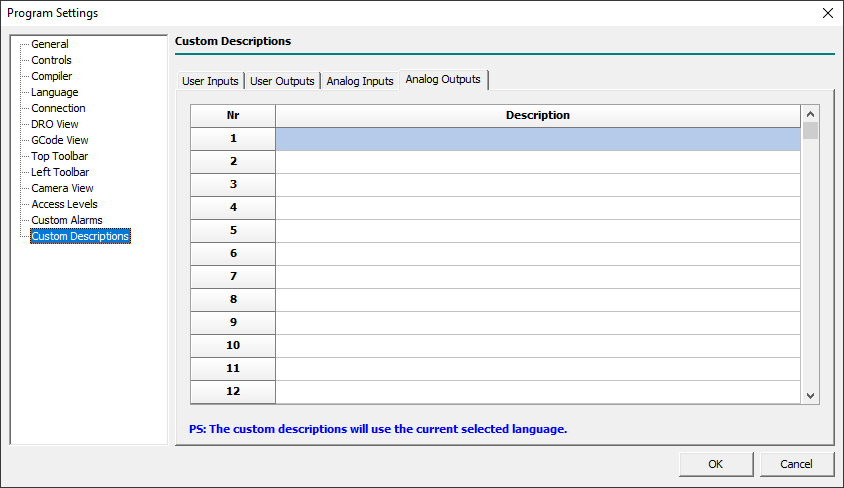

4.14 Custom Descriptions

Through this panel and related sheets, it is possible to define the custom descriptions for user inputs/outputs and analog inputs/outputs.

For the custom descriptions, only chars from the ANSI chars set are usable.

Every language supported by Control Software will have its messages so if the English language is active the showed/entered messages in the grid will be for English.

To Enter the descriptions for a different language select what in the Language panel then enter related text in the grid.

All messages are stored in the external file rosettacnc.ini, of the current machine, and they could be also edited with an external editor in the ANSI char format.

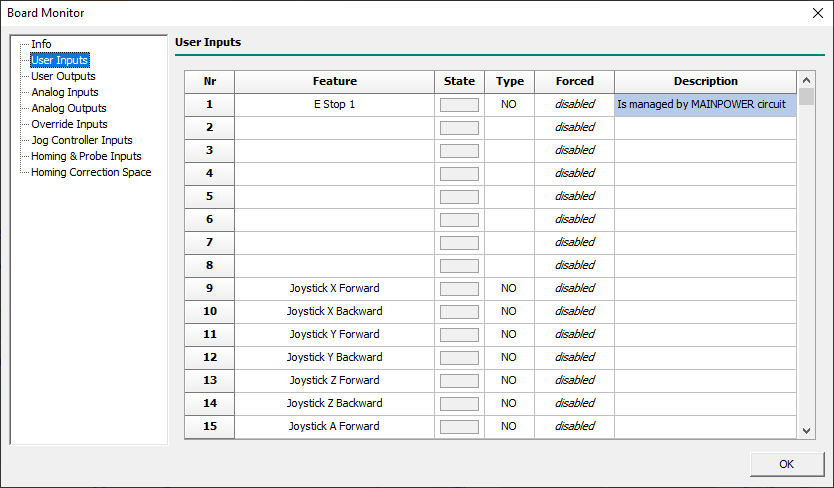

The custom descriptions will be used and shown in the Board Monitor panel reachable with the menu Setup→Board Monitor.. when the Control Software is connected with a CNC Board:

The Board Monitor is enabled to permits direct editing of the description fields in the currently active language.

4.14.1 User Inputs

This sheet permits editing of the user inputs custom descriptions.

The field Nr corresponds to the user input number (eg: 1 = user input 1).

The field Description will contain the custom description text in the currently active language.

4.14.2 User Outputs

4.14.3 Analog Inputs

4.14.4 Analog Outpus

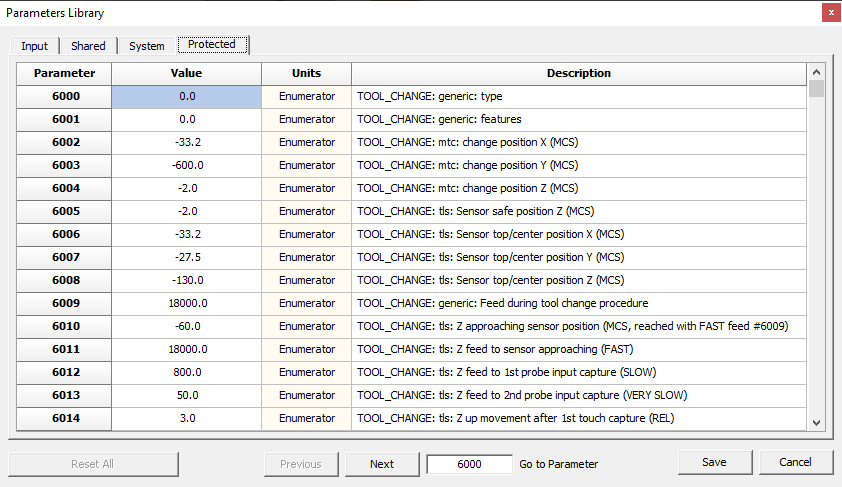

6. Board Settings

Some of the following CNC Board Settings are also accessible in the G-Code programming language via the corresponding read-only Named Parameters.

When available, the Named Parameter will be visible next to the parameter description, e.g.:

- Machine Type - [

#<cnc.machine_type>]

All CNC Board Settings, and related named parameters, will be exclusively in the Metric Measurement System.

6.1 General

The General panel contains the generic CNC settings.

- Condition that Enables the Update of Settings

- The OK button of the Board Settings panel will be always enabled with Control Software non-connected to the CNC Board.

- When the Control Software is connected to the CNC Board, the status of the OK button depends on the following settings:

- Only when axes are stopped

- The OK button is enabled when there are no movements in execution (CNC in

IDLE/ALARMstate).

- Only when axes are disabled

- The OK button is enabled when Board State is in

WAIT MAIN POWER. - To enter in

WAIT MAIN POWERis necessary to have assigned a digital input to the feature Main Power Input on the Inputs sheet.

- Action To Do if Disconnected in RUN State

- When the connection between the PC and the CNC is interrupted a timeout timer of 4 seconds starts.

- At the end of that, if the CNC is in the RUN state, it automatically switches the CNC to one of the following new states:

- Go To PAUSE State

- The CNC enters in

PAUSEstate.

- Go To ALARM State

- The CNC enters in

ALARMstate.

6.1.0.1 General Settings for Homing

- Velocity Divider

- This is the parameter that defines the ratio between the homing velocity (used when an axis starts the Homing sensor search movements)

- and the final homing switch search movement.

- Example:

- If you set Home Velocity Divider to 10 and the X-Axis Homing Velocity is 6000mm/min, the Homing switch search speed will be 600mm/min.

- Allowed Commands without Homing Done

- Xxx.

6.1.0.2 Withdraw/Retract Tool at Stop Settings

- Withdraw/Retract Tool feature permits to define what CNC has to do when a STOP action is requested to CNC (eg: STOP user input becomes ACTIVE).

- It permits to extract the tool from the stock of a desired distance and velocity.

- After Withdraw/Retract Tool action CNC will execute the STOP action and will enter in

IDLEstate.

- TAKE CARE: If the CNC has not searched for the reference point (homing), the CNC will not carry out the

Withdraw/Retract Toolprocedure.

- Mode

- With the

Modefield is possible to define what type of Withdraw/Retract Tool action will be done:- Disabled

- At the

STOPrequest no Withdraw/Retract action is executed, and the CNC job stops immediately.

- Normal

- At the

STOPrequest the Z-axis moves UP of space defined in theDistancefield. - The requested

Distancewill be limited to Z-axisMax Limitvalue. - This is the common option for Kinematics: Trivial, Independent Rotational Axes, Rotary Table A/C, and Rotary Table B/C.

- Along Tool Direction

- At the

STOPrequest the tool will be extracted following the tool direction vector of measure defined in theDistancefield. - The requested

Distancewill be limited to axesMax Limitvalues. - This is the common option for Kinematics: Tilting Spindle A/C.

- Distance

- The parameter defines the distance from the current tool position to do to extract the tool from stock.

- Velocity

- The parameter defines the percentage of axis/axes max interpolation velocity to be used during the extraction of the tool from stock.

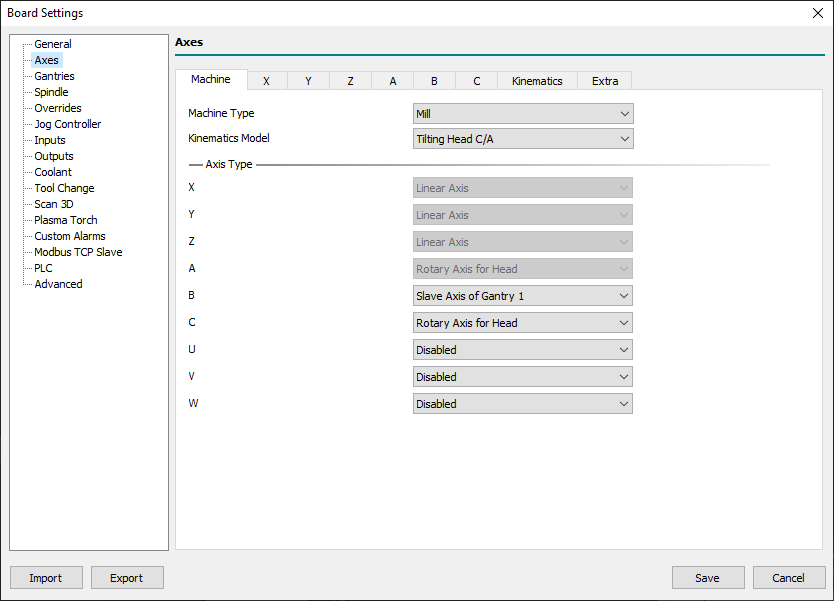

6.2 Axes

The Axes panel contains the CNC Board settings for movement axes.

The panel is subdivided into a variable number of sheets that vary according to what is set in the parameters Machine Type, Kinematics Model, and Axis Type.

6.2.1 Machine

Before beginning to set the axes parameters it is necessary to define the machine configuration.

In this sheet are collected all main settings required to do that.

- Machine Type - [

#<cnc.machine_type>]

- This is the parameter that defines the machine type.

- At the moment the field is disabled and fixed to Mill which means: Mill and Mill/Turn machine.

- Kinematics Model - [

#<cnc.kinematics_model>]

- The CNC Board supports a fixed set of Kinematics to cover all common Mill and Mill/Turn configurations:

- Trivial

- There is a 1:1 correspondence between joints and axes. Most standard milling machines and lathes use the trivial Kinematics model.

- The simplest machines are those in which each joint is placed along with one of the Cartesian axes.

- The toolpath graphic representation will be rendered according to axis positions.

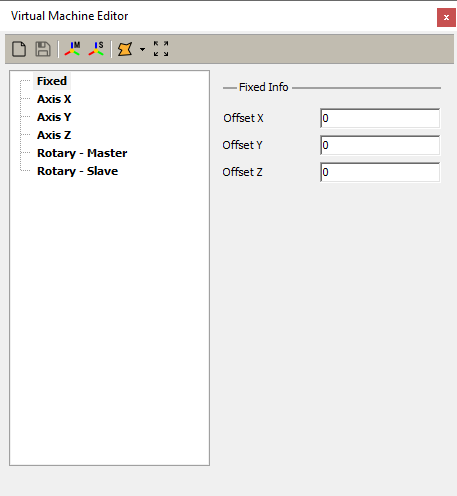

- The Virtual Machine Engine does not support the Trivial model so the VM Parts Geometries will not follow the movements of axes.

- Independent Rotational Axes

- With this Kinematics model, the toolpath will be rendered according to Rotational Axes settings.

- Rotational axes set to

Free Rotary Axiswill not be rendered in toolpath graphic and uses as a linear axis with degrees as um. - Rotational axes set to

Rotary Axis for Tablewill concur to toolpath graphic representation according toKinematicssheet settings. - The Virtual Machine Engine will fully support the VM Parts Geometries following the movements of axes.

- Rotary Table A/C

- Xxx.

- With this Kinematics the Master Rotary Axis is A (turn around X-Axis) and the Slave Rotary Axis is C.

- The Virtual Machine Engine will fully support the VM Parts Geometries following the movements of axes.

- Rotary Table B/C

- Xxx.

- With this Kinematics the Master Rotary Axis is B (turn around Y-Axis) and the Slave Rotary Axis is C.

- The Virtual Machine Engine will fully support the VM Parts Geometries following the movements of axes.

- Tilting Head C/A

- Xxx.

- With this Kinematics the Master Rotary Axis is C and the Slave Rotary Axis is A.

- The Virtual Machine Engine will fully support the VM Parts Geometries following the movements of axes.

- Tilting Head A/B

- Xxx.

- With this Kinematics the Master Rotary Axis is A and the Slave Rotary Axis is B.

- The Virtual Machine Engine will fully support the VM Parts Geometries following the movements of axes.

- Axis Type - [

#<cnc.x.type>..#<cnc.w.type>]

- Depending on the kinematic model chosen, each axis can be set to a range of possible axis types:

- Disabled - [

#<axis.type.disabled>]

- The Axis is disabled and can't be used in G-Code.

- If a disabled Axis is used in the G-Code Program, Macros, or MDI, a compile error will be raised.

- Linear Axis - [

#<axis.type.linear>]

- The Axis is of linear type.

- Free Rotary Axis - [

#<axis.type.rotary_free>]

- The Axis is of the free rotary type.

- A free rotary Axis doesn't have any Kinematics management and its behavior is very close to Liner Axis but use the degree as space units.

- Rotary Axis for Head - [

#<axis.type.rotary_head>]

- Xxx.

- Rotary Axis for Table - [

#<axis.type.rotary_table>]

- Xxx.

- Slave Axis of Gantry 1 - [

#<axis.type.gantry_1>]

- Xxx.

- Slave Axis of Gantry 2 - [

#<axis.type.gantry_2>]

- Xxx.

6.2.1.1 Axes Types for Kinematics Type Mill (Mill/Turn)

- At least two linear axes must be enabled to permits G-Code compilation.

- Axes Types fields in Bold are pre-defined depending on selected Kinematics.

Follow description of Axes Types available with Kinematics of Mill (Mill/Turn) Machine Type:

| Mill Kinematics Type | Axes Types |

|---|---|

| Trivial |

|

| Independent Rotational Axes |

|

| Rotary Table AC |

|

| Rotary Table BC |

|

| Tilting Spindle AC |

|

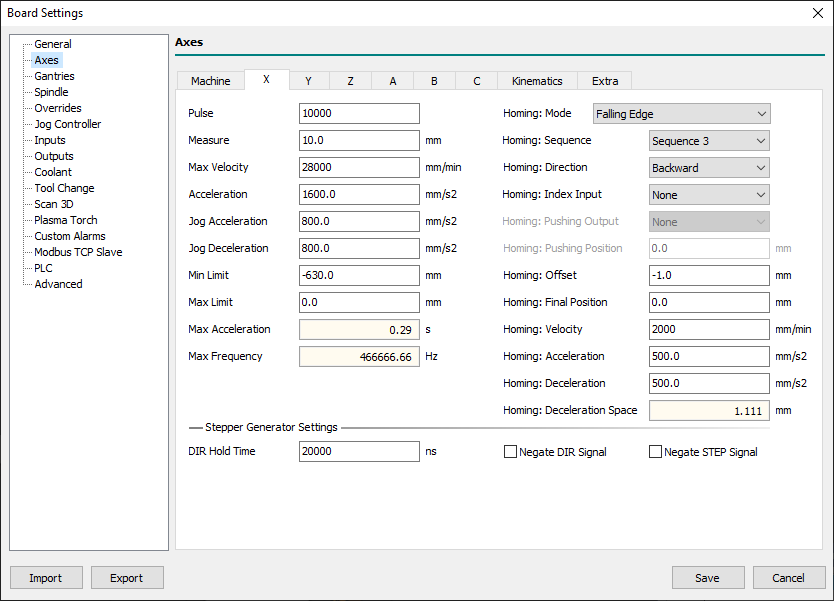

6.2.2 X .. W

- This panel is the same for axis X to W.

- Available named parameters are reported for X-axis (eg:

#<cnc.x.min_lim>) but are available for every axis from X to W, just change the axis letter.

- Pulse

- Define the impulses necessary to obtain a complete revolution of the motor.

- For steppers motors, this parameter must include the micro-steps so if you have a 200 pulse motor with 8 micro-steps in the driver, you need to set it to 1600.

- For brushless motors, you have to set it to the same pulses set in the driver for a complete revolution.

- Measure

- It is the movement made by the axis with a complete revolution of the motor.

- Max Velocity - [

#<cnc.x.max_vel>] - Defines the maximum velocity value of motor in mm/min and is used with the rapid movements ( Eg:

G00). - It is also the base velocity used to get other CNC movement velocities, as for Jog, Homing, etc.

- Acceleration - [

#<cnc.x.acc>] - Defines the rate of change of interpolated velocity in time and is expressed in mm/s².

- Interpolation acceleration and deceleration share the same value in axis settings.

- The acceleration can be influenced by override when

Override Modeis set toSpeed and Space. - With the

G104command is possible to define a different acceleration/deceleration value for the interpolated point.

- Jog Acceleration

- Defines the rate of change of axis velocity in time during a Jog action acceleration and is expressed in mm/s².

- Jog Deceleration

- Defines the rate of change of axis velocity in time during a Jog action deceleration and is expressed in mm/s².

- Min Limit - [

#<cnc.x.min_lim>]

- Defines the minimum boundary of the axis in mm.

- Max Limit - [

#<cnc.x.max_lim>]

- Defines the maximum boundary of the axis in mm.

- Acceleration Time

- Shows the time required to reach the axis maximum velocity starting from 0.

- Max Frequency

- Shows the maximum frequency used to reach the axis maximum velocity.

- This value can help to understand if the chosen axis configuration is compatible with CNC Board or Axis Driver specifications.

- During the CNC Board order is necessary to choose the maximum STEP/DIR frequency of axes pulse generator between 125/250/500/1000 Hz.

- Every STEP/DIR driver has a maximum frequency acceptable for STEP/DIR signal that must be equal or major than the

Max Frequencyvalue.

- Homing: Mode

- Define the axis homing modality (Home Search chapter).

- Every axis can have a different homing mode choosing from:

- Disabled

- In this mode, nothing is done when the Homing Search procedure is started.

- The axis position already appears black to indicate that the machine position is synchronized.

- No Movement

- In this mode, no movement is commanded to the axis when the Homing Search procedure is started.

- The axis machine position is directly loaded with the parameter

Homing: Offsetvalue. - This mode is used when the CNC has no Homing Sensors.

- Thus the Homing Search procedure is started when the operator manually jogs the axes to the machine reference point.

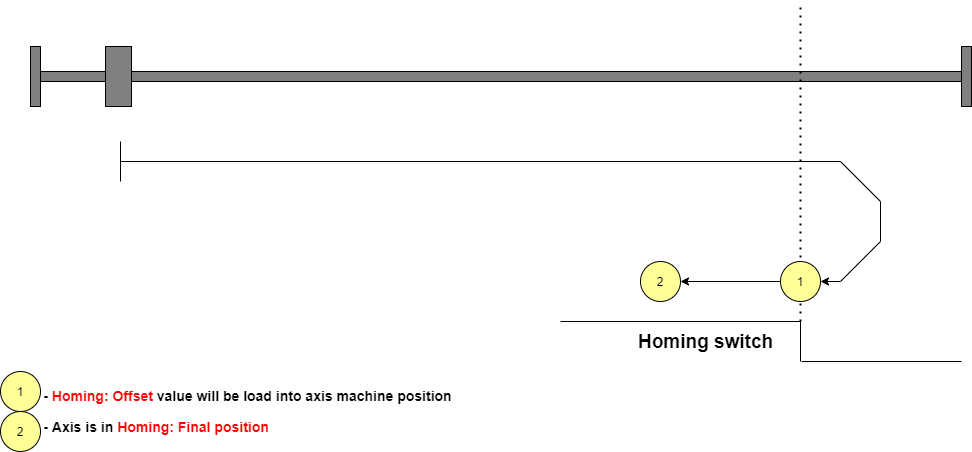

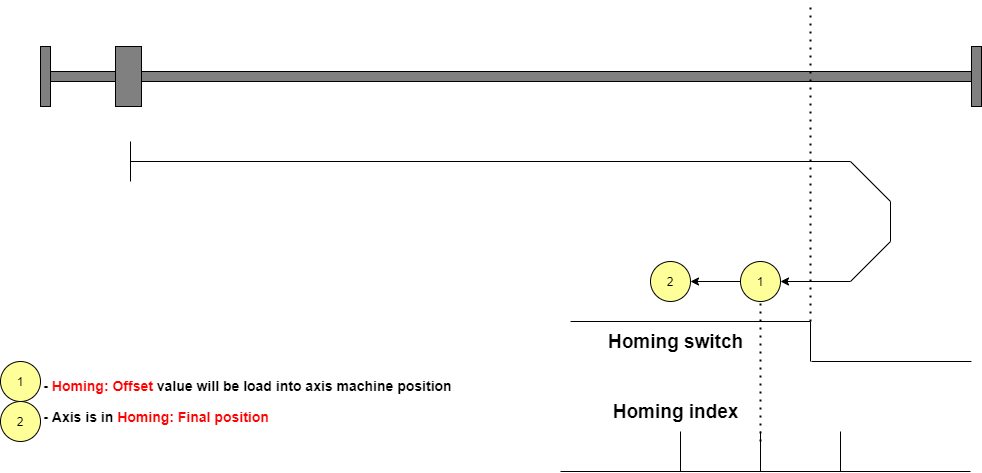

- Rising Edge

- In this mode, the Homing Search procedure is:

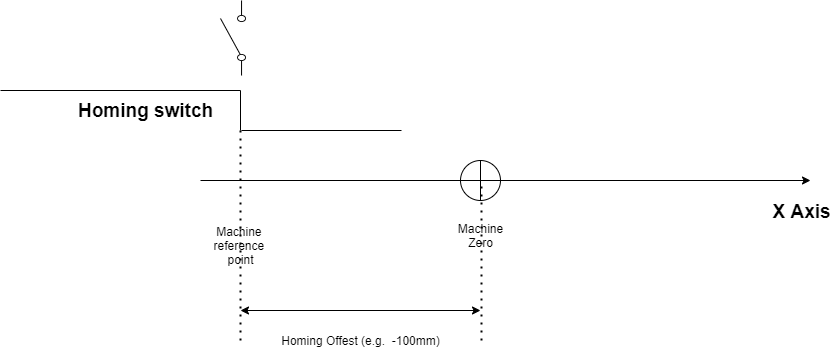

- 1] The axis moves to the selected direction in

Homing: DirectionatHoming: Velocityfeed until the axis meets the Homing sensor. - 2] Then axis reverse direction and decrease velocity by a factor defined by the general parameter

Velocity Divider. - 3] When the Homing sensor escapes, the

Homing: Offsetvalue will be loaded into the axis machine position. - 4] Finally the axis is moved to

Homing: Final Position.

- Falling Edge

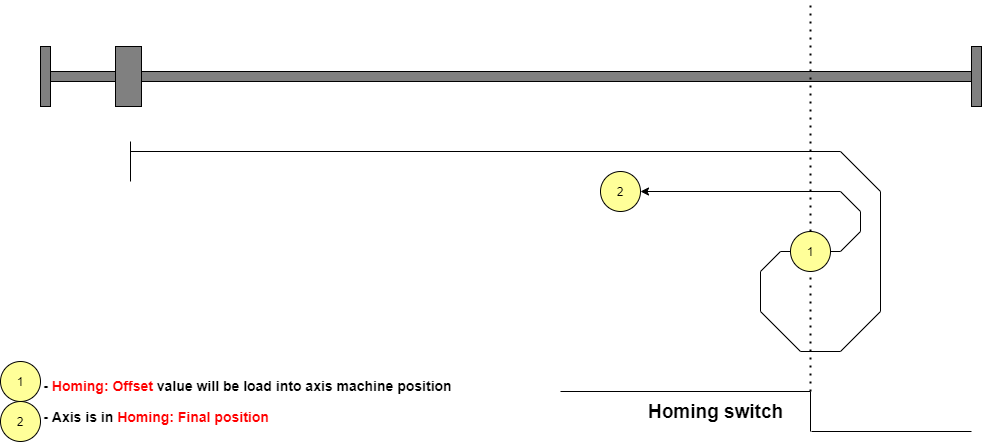

- This mode is very similar to Rising Edge but when the Homing sensor escapes, the axis will reverse direction again and load the machine position when the axis meets the homing sensor.

- This mode is used if the Homing sensor has a higher precision in the switching edge opposite to that defined in Rising Edge mode.

- Use of this modality in combination with the

Homing: Index Inputis not permitted.

- Absolute

- This mode is used in the EtherCAT servo drive with an absolute encoder.

- No movement is commanded to the axis when the Homing Search procedure is started.

- The axis machine position will be loaded with the resulting value from the Servodrive position minus

Homing: Offsetvalue.

- Absolute with Final Position

- Is the same as Absolute mode but after the load of the machine position the axis is moved to

Homing: Final Position.

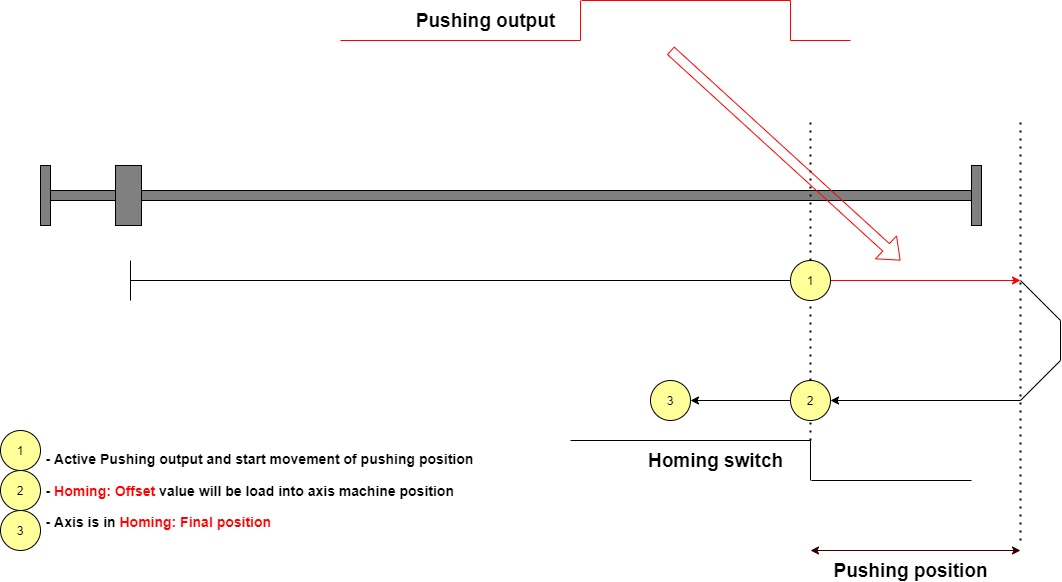

- Pushing

- Xxx.

- Pushing Switch Rising Edge

- Xxx.

- Pushing Switch Falling Edge

- Xxx.

- Homing: Sequence

- Define the homing sequence during a Homing All axes action.

- When a “Homing All Axes” action is required at first all axes with

Sequence= 1 will be referenced. - After will follow all axes with

Sequence= 2 and so on tillSequence= 6. - To improve the axis homing quality is a good choice to have only one axis in the movement at a time.

- Homing: Direction

- Xxx.

- Homing: Index Input

- Xxx.

- Homing: Pushing Output

- Xxx.

- Homing: Pushing Position

- Xxx.

- Homing: Offset

- Xxx.

- Homing: Final Position

- Xxx.

- Homing: Velocity

- Xxx.

- Homing: Acceleration

- Xxx.

- Homing: Deceleration

- Xxx.

- Homing: Deceleration Space

- Xxx.

- Dir Hold time

- Defines the minimum HOLD time, in nanoseconds, of DIR signal in the STEP/DIR generator.

- The default value of 20000 should work for 99.99% of common drivers and don't should be modified.

- The value is however modifiable for very low-quality motor drivers where required minimum time is higher.

- Negate DIR Signal

- Permits to invert DIR signal value and so reverse motor direction.

- This can be useful when the motor movements result inverted in direction to avoid to change cabling.

- Negate STEP Signal

- Permits to invert STEP signal.

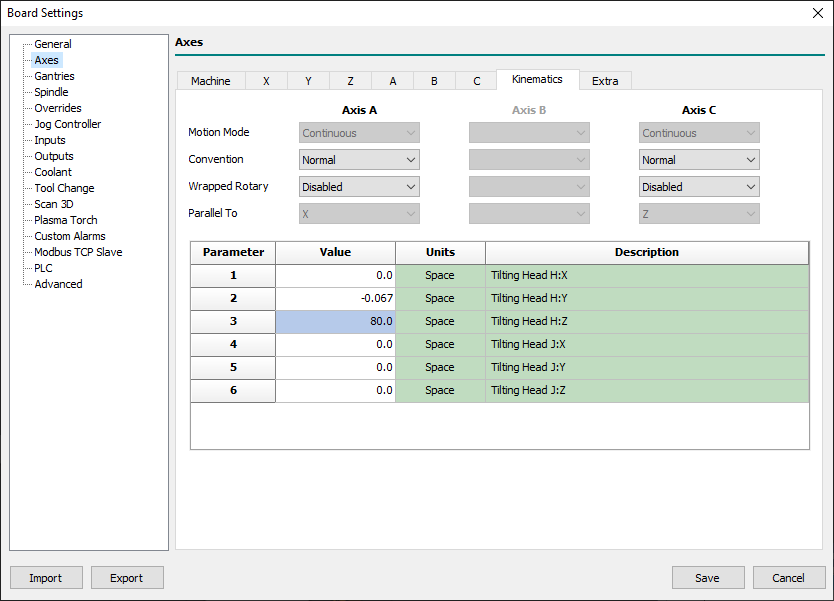

6.2.3 Kinematics

- Use this sheet to configure machine kinematics parameters.

- The proposed fields change and reflect the Kinematics Model and Axis Type defined in Axes→Machine sheet.

- Motion Mode

- Xxx…

- Convention

- Xxx…

- Wrapped Rotary

- Xxx…

- Parallel To

- Xxx…

- Kinematics parameters table

- Xxx…

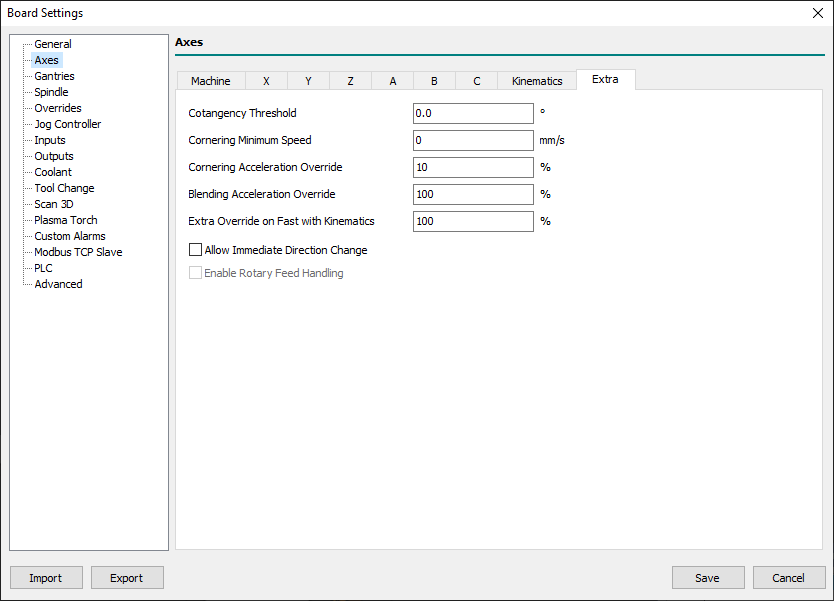

6.2.4 Extra

- Cotangency Threshold

- Xxx…

- Cornering Minimum Speed

- Xxx…

- Cornering Acceleration Override

- Xxx…

- Blending Acceleration Override

- Xxx…

- Extra Override on Fast with Kinematics

- Xxx…

- Allow Immediate Direction Change

- Xxx…

- Enable Rotary Feed Handling

- Xxx…

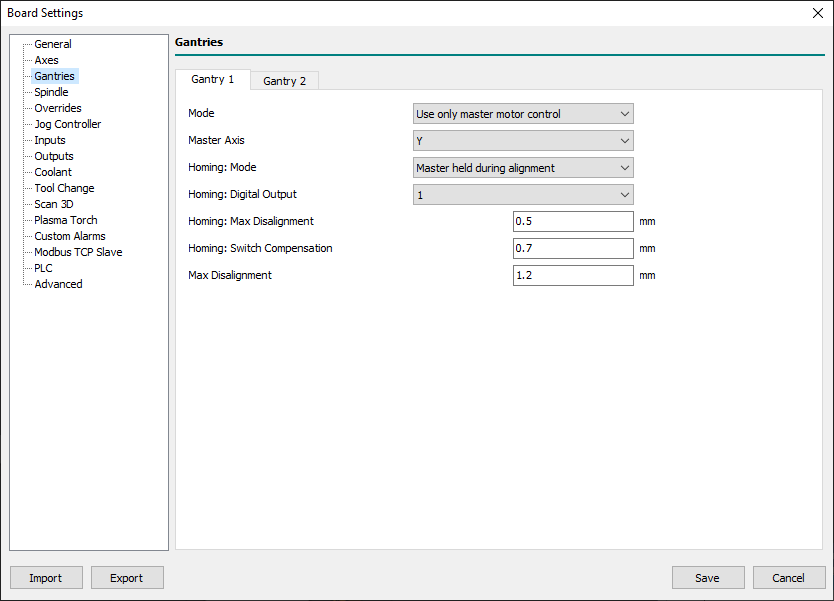

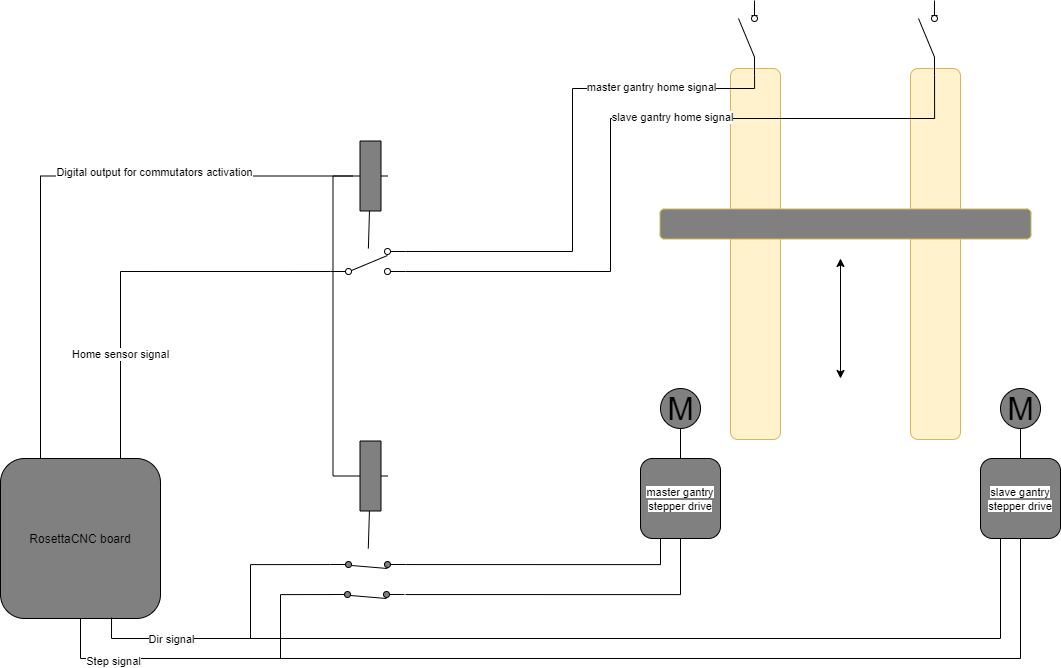

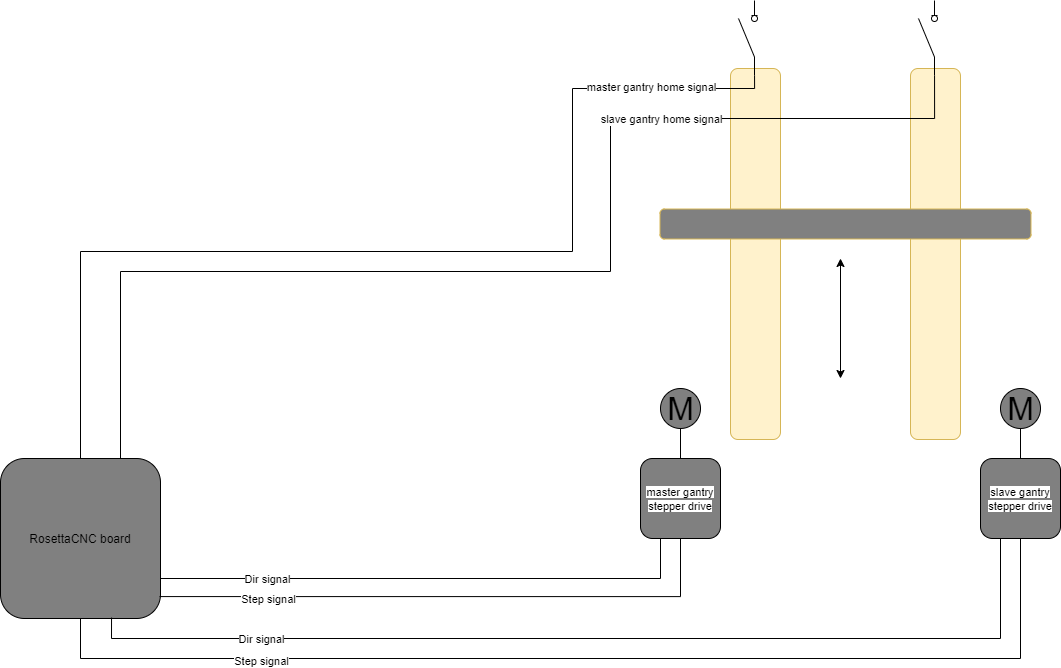

6.3 Gantries

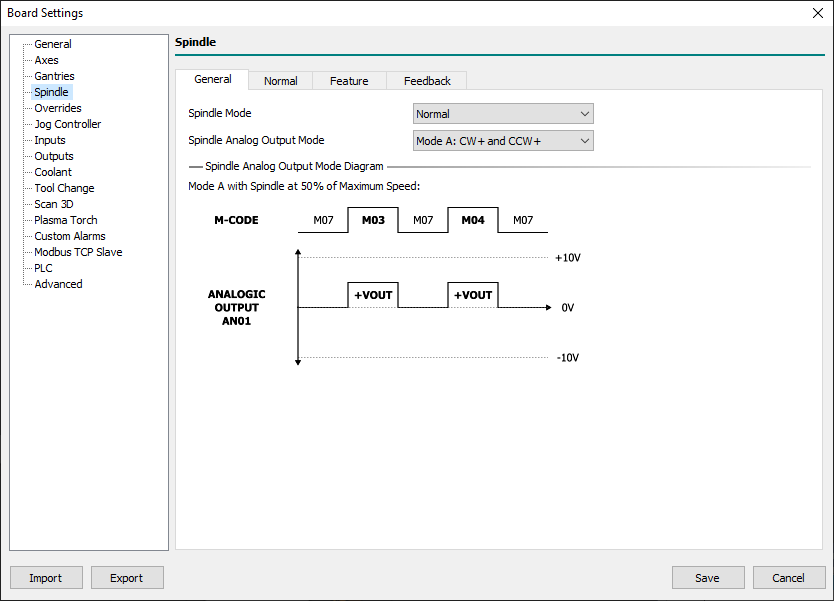

6.4 Spindle

6.4.1 General

- Spindle Mode

- Defines the Spindle type from:

- Normal

- The spindle has only a one-speed range.

- With Automatic Change Ranges

- The spindle system has two or more speed ranges.

- Spindle Analog Output Mode

- Defines the Spindle analog output setting mode:

- Mode A: CW+ and CCW +

- The spindle analog output for clockwise (CW) rotations will use values between 0 to +10V.

- The spindle analog output for counter-clockwise (CCW) rotations will use values between 0 to +10V.

- For a unidirectional spindle, a digital output must be configured to indicate the spindle driver-enabled status.

- For a bidirectional spindle, two digital outputs must be configured to indicate the spindle driver-enabled status and direction of rotation.

- Mode B: CW+ and CCW -

- The spindle analog output for clockwise (CW) rotations will use values between 0 to +10V.

- The spindle analog output for counter-clockwise (CCW) rotations will use values between 0 to -10V.

- For a unidirectional spindle, a digital output must be configured to indicate the spindle driver-enabled status.

- For a bidirectional spindle, two digital outputs must be configured to indicate the spindle driver-enabled status.

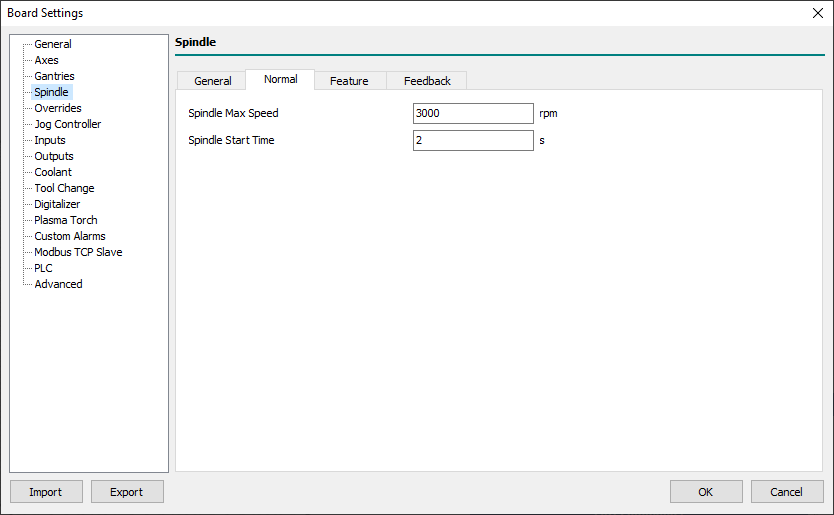

6.4.2 Normal

- Spindle Max Speed

- Defines the maximum speed of the spindle in rpm.

- The entered value corresponds to place 10v in spindle analogic output.

- For e.g. with the field set to 18000 rpm:

- Executing the G-Code

S18000 M03

- The spindle analog output will be placed to 10V (maximum speed) in the clockwise rotation mode.

- Executing the G-Code

S9000 M03

- The spindle analog output will be placed to 5V (half speed) in the clockwise rotation mode.

- Executing a G-Code with an higher RPM value than possible

S30000 M03

- The spindle analog output will be placed to 10V (maximum speed) in the clockwise rotation mode BUT the spindle will reach only its maximum speed.

- Spindle Start Time

- Defines the settling time of the spindle required to reach the programmed speed.

- While waiting for spindle adjustment, the execution of the next block is put on hold.

- The timing starts when:

- The spindle operating status is changed with the

M03/M04/M05commands. - The spindle speed in use is changed with the 'S' command with the spindle on.

- NOTE

- If the spindle supports the feature

At Speed InputorZero Speed Inputthe following behaviors table is applied:

| Spindle State | At Speed Input | Zero Speed Input | Description |

|---|---|---|---|

From M05 to M03/M04 | NO | Spindle Start Time is used to wait for spindle speed settle. |

|

From M05 to M03/M04 | YES | At Speed Input is used to wait for spindle speed settle. |

|

From ON to OFF (M05) | NO | Spindle Start Time is used to wait for spindle speed settle. |

|

From ON to OFF (M05) | YES | Zero Speed Input is used to wait for spindle speed settle. |

|

Switch from M03 or M04 or M04 to M03 |

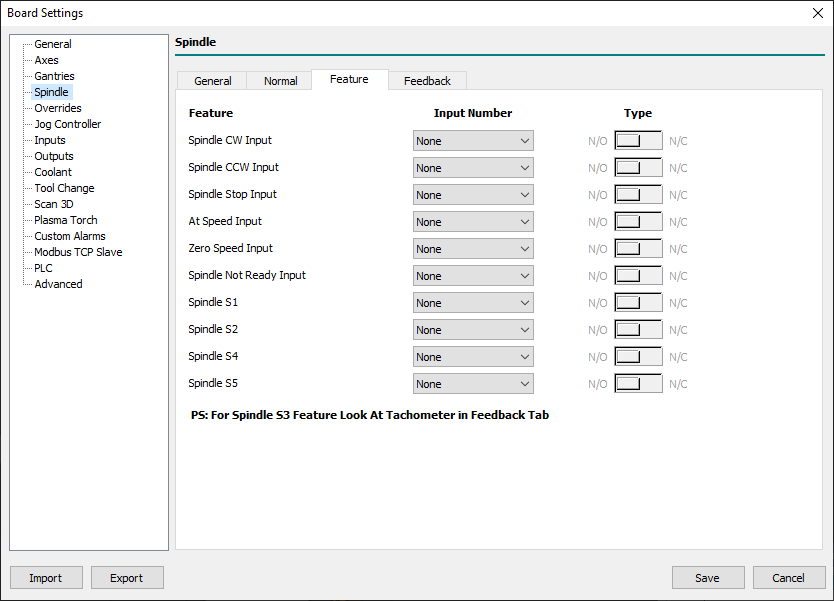

6.4.3 Feature

- Spindle CW Input

- Defines the user input to manually start the spindle in the clockwise direction.

- This input is enabled only in CNC Board

IDLEstate. - The input work in TOGGLE mode when

Spindle Stop Inputis not defined.

- Spindle CCW Input

- Defines the user input to manually start the spindle in the count clockwise direction.

- This input is enabled only in CNC Board

IDLEstate.

- Spindle Stop Input

- Defines the user input to manually stop the spindle.

- At Speed Input Input

- Xxx.

- Zero Speed Input

- Xxx.

- Spindle Not Ready Input

- Xxx.

- Spindle S1

- The Tool-holder cone is attached correctly.

- Spindle S2

- The Collet is open.

- Spindle S4 (Optional).

- HSK cone is locked in the correct position.

- Spindle S5 (Optional).

- The Piston is in the upper position.

- If your ATC spindle provides standard

S1..S5output signals you can enable the CNC Board Spindle Control Signals Check management. - The Spindle Control Signals Check (SCSC) management is disabled if Spindle is OFF (

M05) or during tool change in G-Code inner aM107toM108block. - For the base check

S1andS2are mandatory. - In some ATC spindles, the signal

S4orS5is not available, so these checks are optional, and relatedS4/S5fields must be set toNone.

Status modes of the spindle and corresponding outputs:

| STATE | S1 | S2 | S5 | ACTION |

|---|---|---|---|---|

| Tool-Holder blocked correctly | ON | OFF | ON | It is allowed machining. |

| Collect closed but tool-holder absent | OFF | OFF | ON | The Tool-holder is not engaged correctly. It is not allowed machining. The electrospindle cannot run. |

| Collect open | OFF | ON | OFF | The tool-holder is released. |

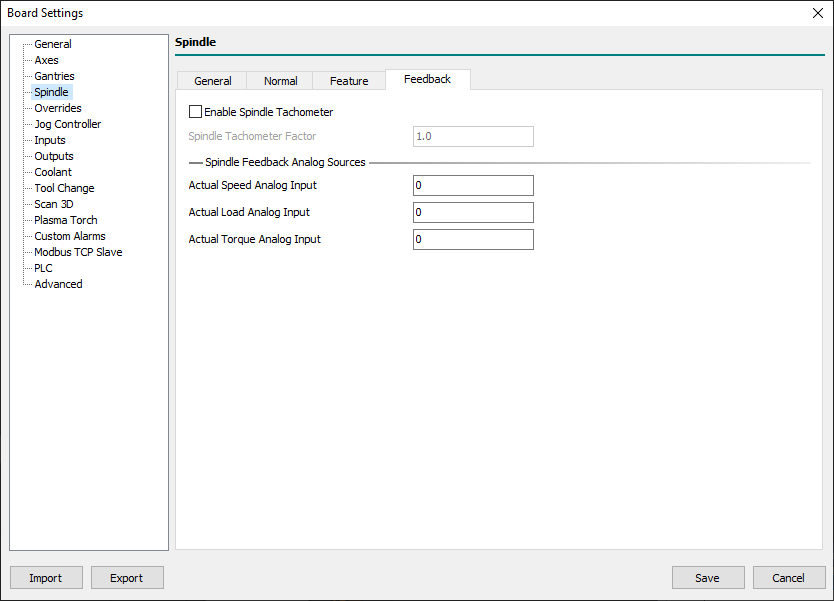

6.4.4 Feedback

Starting from firmware 1.58 Spindle Feedback is available. Spindle speed can be read back by a digital sensor (Tachometer) or Analog input.

- Tachometer

- Read the frequency of the digital signal connected to TACHO terminal. Frequency is read in 0.01 Hz resolution.

- For example, if you apply a 1Hz signal, control software prints 100rpm as the spindle speed.

- To scale this value for the spindle real speed, use the Spindle Tachometer Factor (from 0.001 to 20).

- Also if you need more scaling factor please visit

Program Settings→ DRO View → Spindle 1/2 → Target Speed

- Analog inputs

- Analog inputs can read Speed, motor current (Load) and Torque.

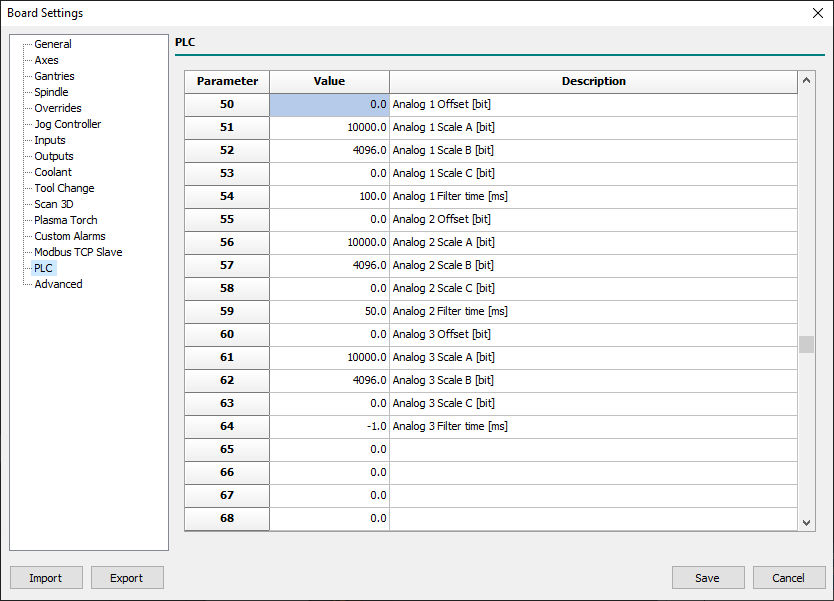

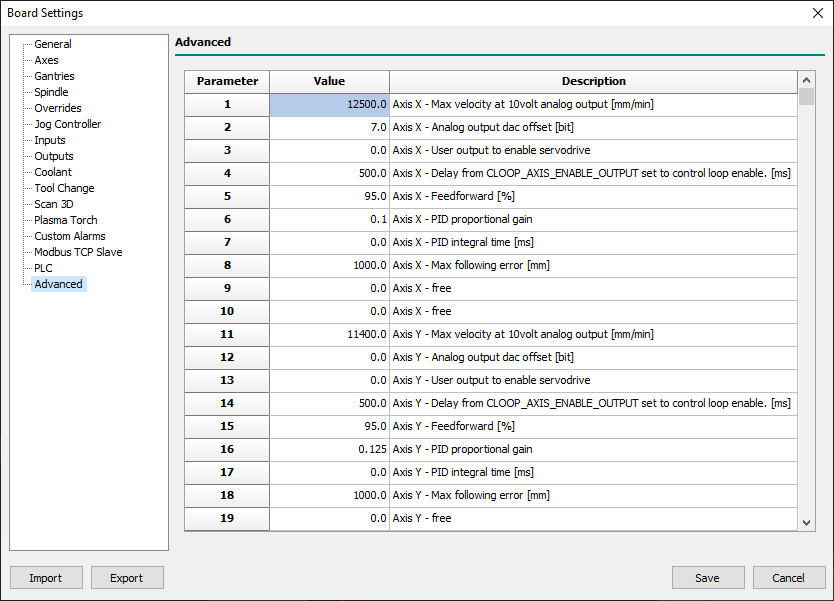

- Set Analog source and PLC parameters from 50 to 64 to scale and filter the source value.

To show spindle feedback data in control software please visit Program Settings→ DRO View panel.

Actually, there is no check on spindle feedback to generate alarms or warnings.

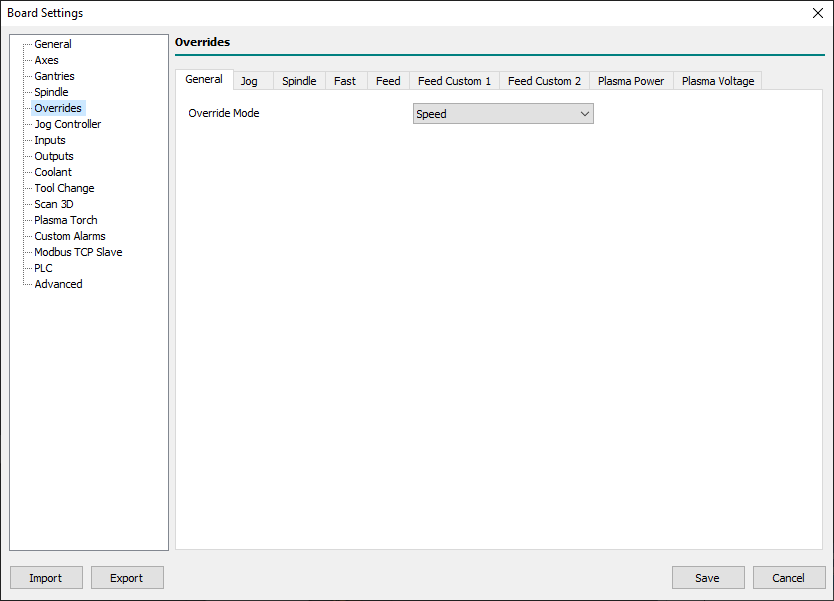

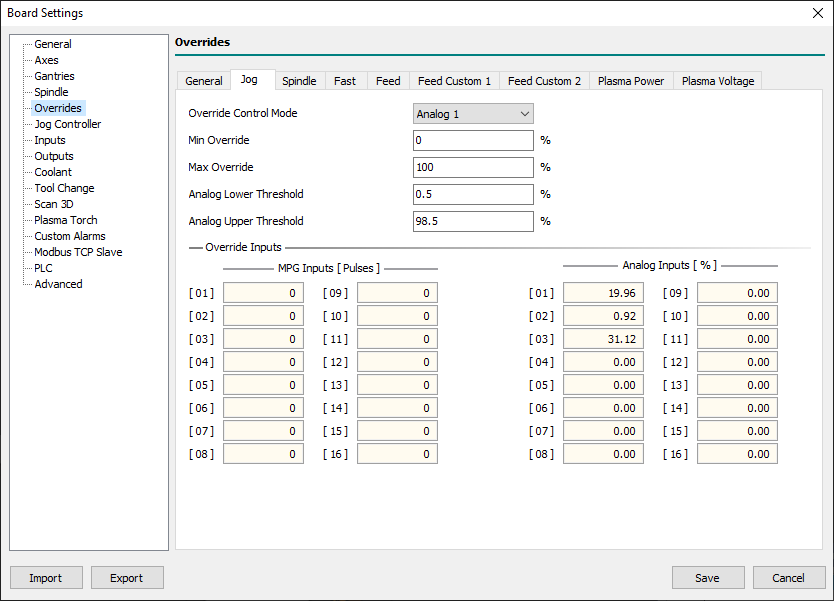

6.5 Overrides

6.5.1 General

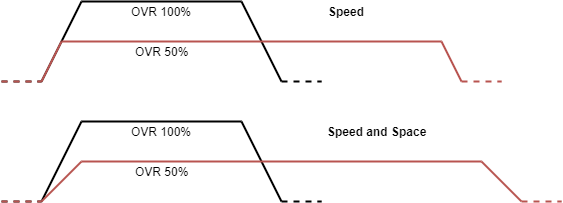

- Override Mode

- This is the main setting that defines how CNC Override System has to work with interpolated movements:

- Speed

- With Override Mode set to Speed the override control has effects only on target speed.

- Speed and Space

- With Override Mode set to Speed and Space mode, the override control has effects on target speed and acceleration/deceleration space.

- IMPORTANT NOTE:

- While validating the Board settings, the Override Mode will automatically be changed to Speed if the Feed → Max Override value is greater than 100%.

6.5.2 Jog/Spindle/Fast/Feed/Feed Custom 1/Feed Custom 2/Plasma Power/Plasma Voltage

This panel is the same for Jog/Spindle/Fast/Feed/Feed Custom 1/Feed Custom 2 features.

The overrides are active depending by M48/M49/M50/M51 commands following this table:

| Command | Spindle | Fast | Feed | Feed Custom 1 | Feed Custom 2 |

|---|---|---|---|---|---|

M48 | ON | ON | ON | off | off |

M49 | off | off | off | off | off |

M50 | unchanged | ON | ON | off | off |

M50 P0 | unchanged | off | off | off | off |

M50 P1 | unchanged | ON | ON | off | off |

M50 P2 | unchanged | off | off | ON | off |

M50 P3 | unchanged | off | off | off | ON |

M51 | ON | unchanged | unchanged | unchanged | unchanged |

M51 P0 | off | unchanged | unchanged | unchanged | unchanged |

M51 P1 | ON | unchanged | unchanged | unchanged | unchanged |

- Override Control Mode

- Every feature can have a different Override Control Mode choosing from:

- None

- Override Control is disabled and the related OVR value is set at 100%.

- MPG 1..16

- Override Control is managed by the chosen MPG Input source.

- Analog 1..16

- Override Control is managed by the chosen Analog Input source.

- Only at PC

- Override Control is managed with a PC Track Bar.

- Min Override

- Defines the minimum override value.

- Max Override

- Defines the maximum override value.

- The maximum accepted value changes according to the destination of the override:

- 100% for Jog and Fast.

- 300% for Spindle, Feed, Feed Custom 1, and Feed Custom 2.

- Analog Lower Threshold

- Defines the analog lower threshold associated with Min Override's value.

- When analogic input reaches or goes below this value the resulting override value will be placed to Min Override.

- Analog Upper Threshold

- Defines the analog upper threshold associated with Max Override's value.

- When analogic input reaches or goes upper this value the resulting override value will be placed to Max Override.

- MPG Input 1..16

- Defines the MPG Input source for override control.

- Analog Input 1..16

- Defines the Analog Input source for override control.

6.5.2.1 Override Inputs

- MPG Input 1..16

- If Control Software is connected to a CNC Board, these fields will show the current values of connected MPG Inputs to help the end-user to choose the right one.

- Analog Input 1..16

- If Control Software is connected to a CNC Board, these fields will show the current values of connected Analog Inputs to help the end-user to choose the right one.

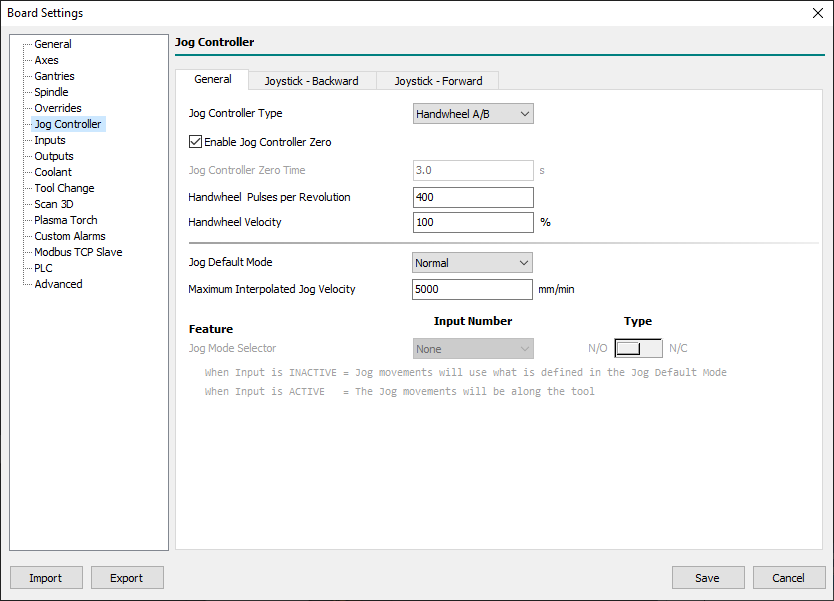

6.6 Jog Controller

6.6.1 General

- Jog Controller Type

- Defines the Jog Controller Type between:

- None

- None Jog Controller is used.

- Handwheel A/B

- Single Joystick

- A Single Joystick is connected with the CNC Board in the Handwheel dedicated connector.

- Multiple Joystick

- A Multiple Joystick is connected with the CNC Board in the Handwheel dedicated connector.

- Enable Jog Controller Zero

- When the

Jog Controller Typeparameter is set toHandwheel A, the Handwheel Enable Button can be used to set to zero the program position of the selected axis. - To do that is necessary to:

- Check if CNC Board is in the

IDLEstate. - Select the desired axis with the Handwheel Axis Selector.

- Press three times the Handwheel Enable Button in the time defined in the

Jog Controller Zero Timeparameter.

- If all was well done the selected axis program position will be set to zero value and the axis machine position will be placed in the active WCS of the axis.

- Jog Controller Zero Time

- Defines the check time for the

Enable Jog Controller Zeroprocedure.

- Handwheel Pulses per Revolution

- Defines the number of pulses per revolution supplied by the handwheel MPG so that one revolution of the handwheel will move the axis of the desired measurement in x1/x10/x100.

- Normally if the handwheel declares 100 PPR the CNC, reading the 4 fronts of the A/B phases will count 400 (x4) so 400 should be introduced in this field.

- In CNCs for precision mechanics, with an MPG of 100 PPR, it is customary to enter a value of 4000 so that an MPG rotation in x1 gives a displacement of 0.1mm.

- Handwheel Velocity

- Xxx…

- Jog Default Mode

- Xxx…

- Maximum Interpolated Jog Velocity

- Xxx…

- Jog Mode Selector

- Xxx…

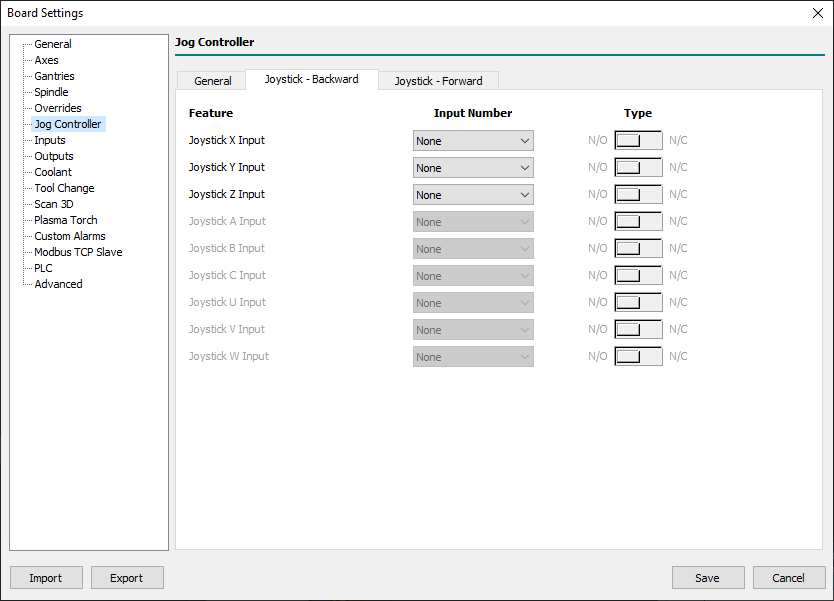

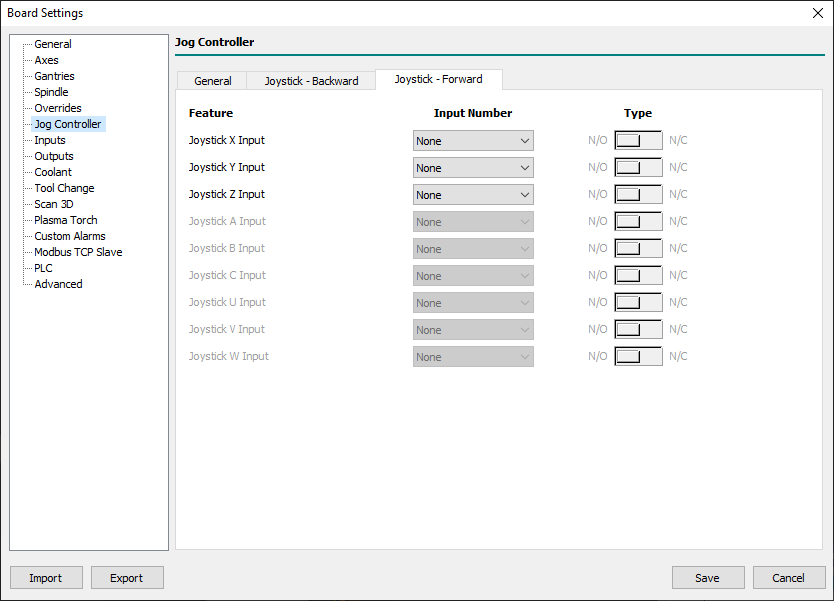

6.6.2 Joystick - Backward

6.6.3 Joystick - Forward

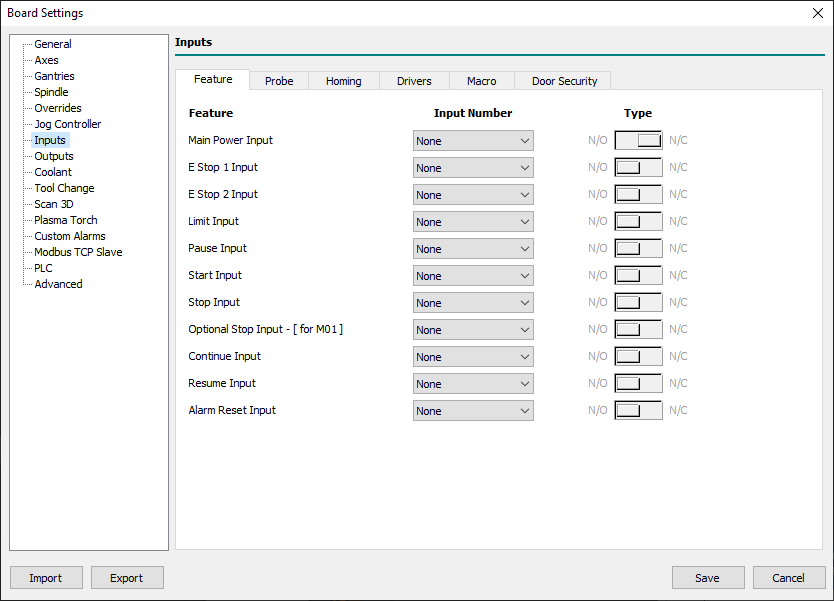

6.7 Inputs

6.7.1 Feature

- Main Power Input

- Xxx…

- E Stop 1 Input

- Xxx…

- E Stop 2 Input

- Xxx…

- Limit Input

- Xxx…

- Pause Input

- Define the User Input for the machining Pause feature.

- The Pause Input is checked only when the CNC Board is executing a G-Code program/macro/MDI e CNC Board is or must enter in

RUNstate. - The input works on the level therefore as long as the input is active and the CNC board is executing a G-Code program/macro/MDI it remains in the “PAUSE” state.

- The CNC Board will back to the

RUNstate when User Input will be deactivated. - When Pause Input is active and the operator run a new G-Code program/macro/MDI the CNC Board automatically changes from

IDLEtoPAUSEstate.

- Start Input

- Xxx…

- Stop Input

- Xxx…

- Optional Stop Input - [ for M01 ]

- Xxx…

- Continue Input

- Xxx…

- Resume Input

- Xxx…

- Alarm Reset Input

- Xxx…

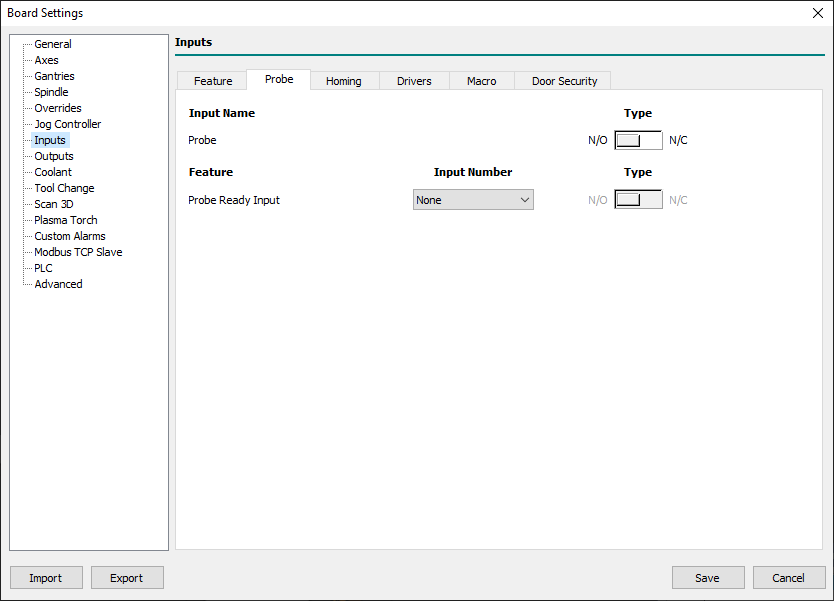

6.7.2 Probe

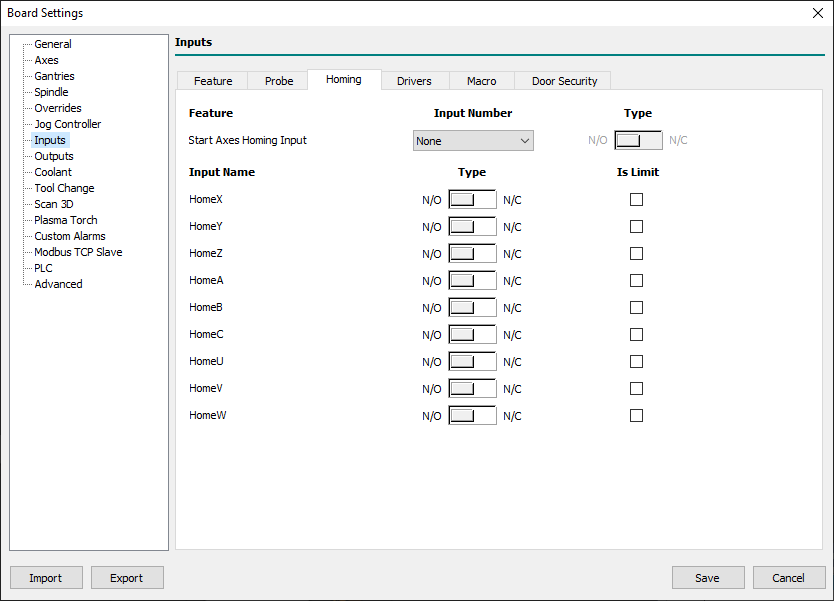

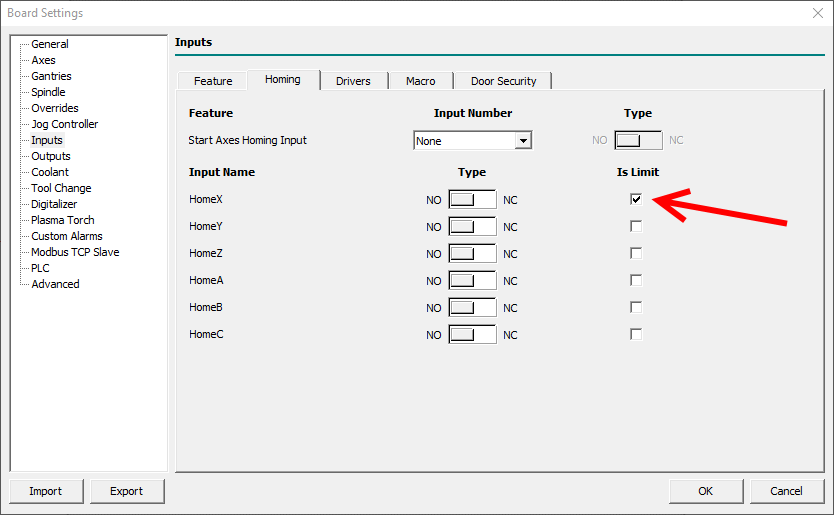

6.7.3 Homing

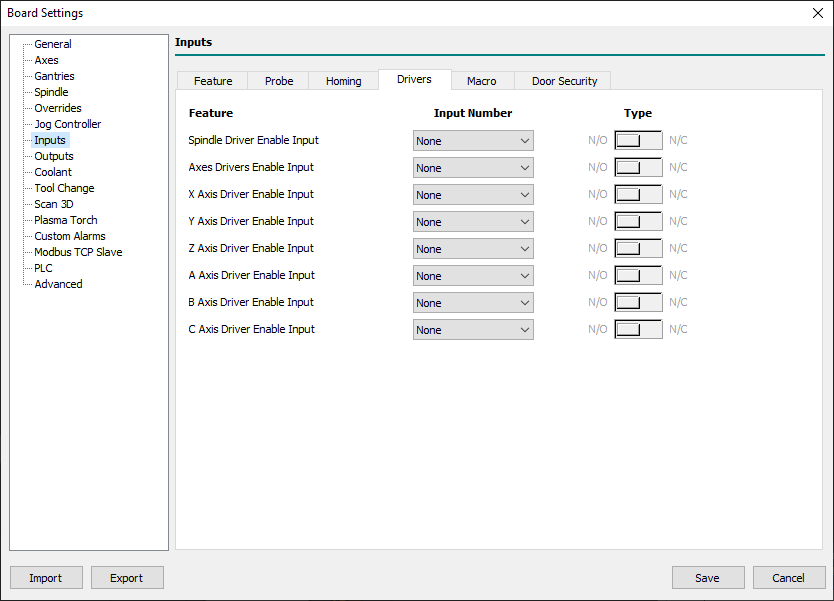

6.7.4 Drivers

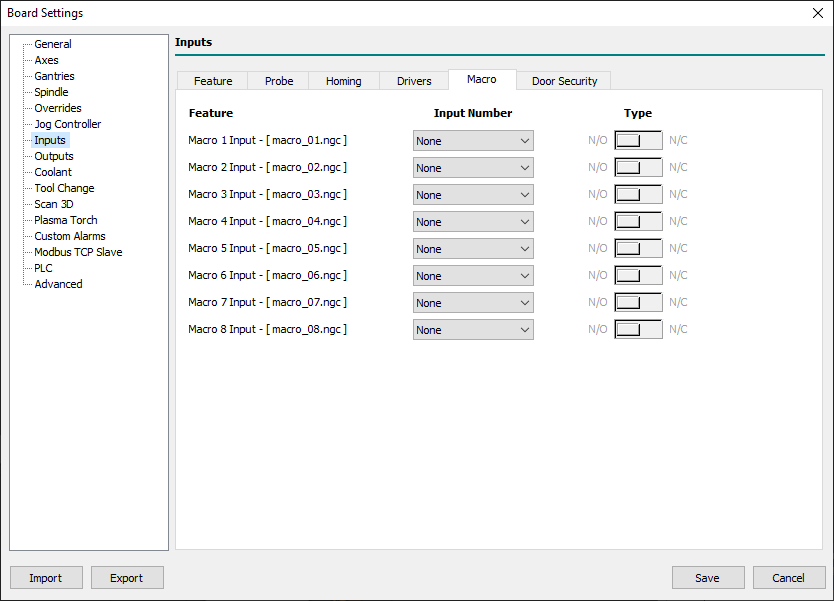

6.7.5 Macro

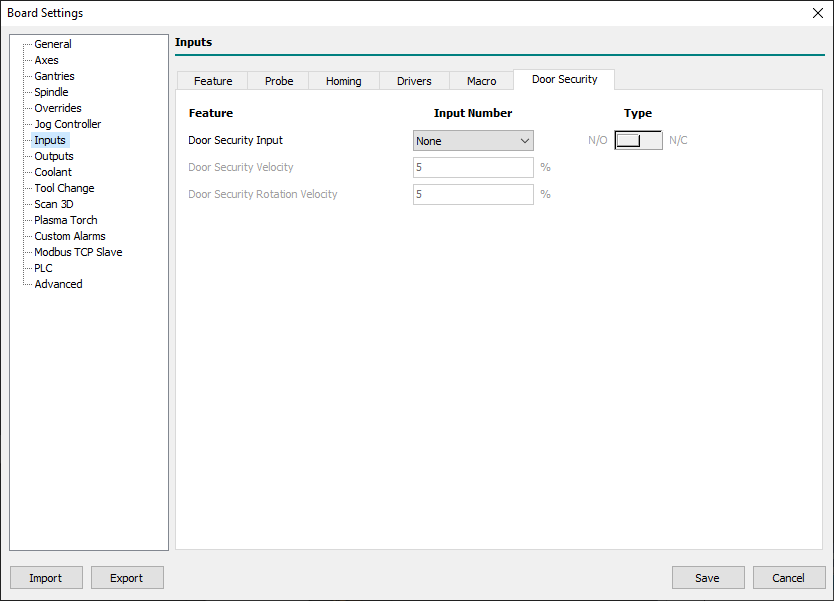

6.7.6 Door Security

6.8 Outputs

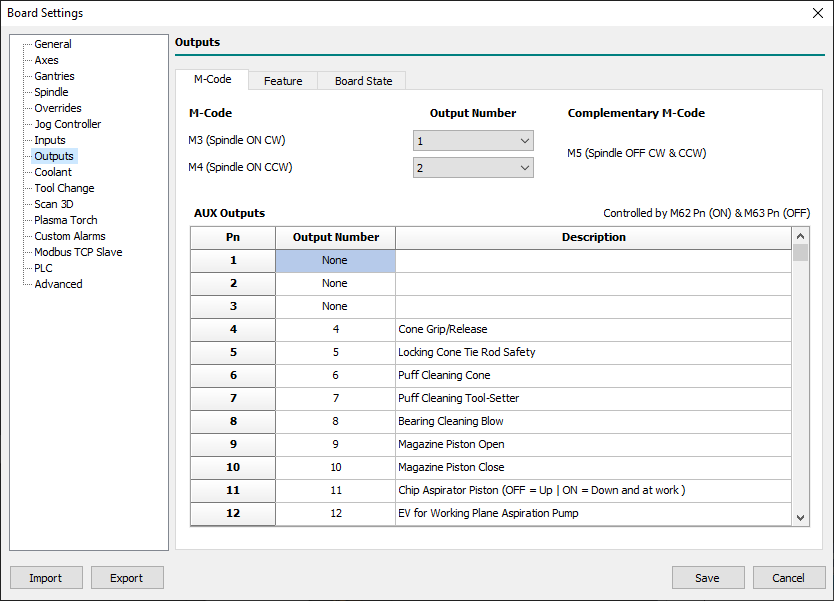

6.8.1 M-Codes

- M3 (Spindle On CW)

- Defines the User Output for spindle ON in the clockwise direction.

- M4 (Spindle On CCW)

- Defines the User Output used for spindle ON in the counter-clockwise direction.

- AUX Outputs

- Defines the association between G-Code AUX outputs and the User Outputs.

- To modify the state of a User Output between G-Code there are two commands:

M62 P<aux_number>(Turn AUX Output ON) andM63 P<aux_number>(Turn AUX Output OFF). - The available G-Code AUX Outputs are 32 and can be mapped to actual User Output using this table.

- To be simple in G-Code reading, when possible, try to keep a 1:1 correspondence between AUX and User Output number, so AUX 1 corresponds to User Output 1.

- However, you can also say that AUX 3 is User Output 1 and a

M62 P3will put ON the User Output 1.

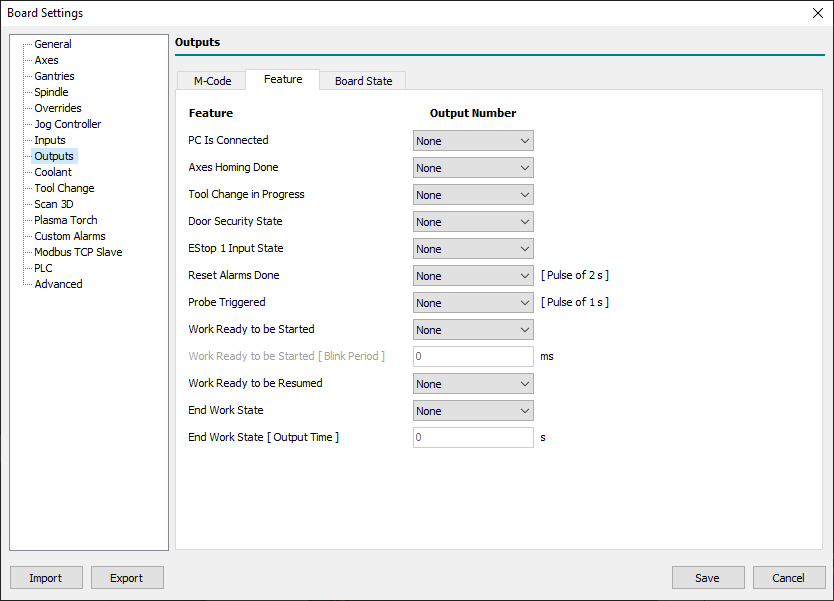

6.8.2 Feature

- PC Is Connected

- Specified user output is

ONwhen a connection between PC Control Software and CNC is established. - When connection falls the output will be

ONfor a timeout time of 4 seconds during that buffered program will continue to work. - If the connection will be restored before timeout finishes the system will continue to work normally.

- Tool Change in Progress

- The specified user output will be

ONduring a tool change procedure invoked with aM06command. - When in the G-Code a

M6is called, the macrotool_change.ngc, with tool change program code, is executed. - At the top of this macro a

M107will inform the PLC the BEGIN of tool change procedure and the specified user output will beON. - At the end of this macro a

M108will inform the PLC the END of tool change procedure and the specified user output will beOFF.

- Axes Homing Done

- When all the enabled axes reach the state of

Homing Donethe specified user output will beON. - When the CNC enters in

ALARMstate the specified user output will beOFF(if CNC is controlling stepper motor).

- Board in WAIT MAIN POWER State

- The specified user output will be

ONwhen the CNC is in theWAIT for MAIN POWERstate.

- Board in RUN State

- The specified user output will be

ONwhen the CNC is in theRUNstate.

- Board in PAUSE State

- The specified user output will be

ONwhen the CNC is inPAUSEstate.

- Board in ALARM State

- The specified user output will be

ONwhen the CNC is inALARMstate.

- Board Not in ALARM State

- The specified user output will be

ONwhen the CNC isn't inALARMstate.

- Door Security State

- Xxx.

- Reset Alarms Done

- The specified user output will be

ONfor 2 seconds when the user resets the Alarms and the CNC exits from theALARMstate. - This output is usually used to reset the fault state in servo drive or spindle inverter.

- Work Ready to be Started

- The specified user output will be

ONwhen a G-Code program is loaded and ready to be started.

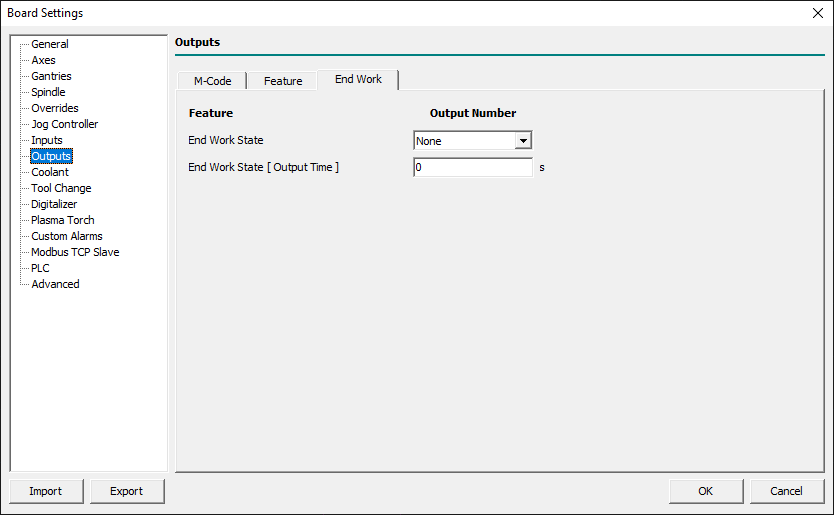

6.8.3 End Work

- End Work State

- The specified user output will be OFF when CNC State changes from SM_IDLE to a working state [SM_RUN, SM_PAUSE, SM_JOG, etc].

- The specified user output will back to ON, after the defined delay time, when the CNC State back to SM_IDLE state.

- If the running CNC activity stops for a STOP/ALARM event the specified user output will be not placed to ON.

- The output

End Work Statewill be switched ON only after thatEnd Work State [ Output Time ]has elapsed with the CNC Board in theSM_IDLEstate.

- End Work State [ Output Time ]

- Defines the delay time from the end of program execution after that the

End Work Statewill be turned ON.

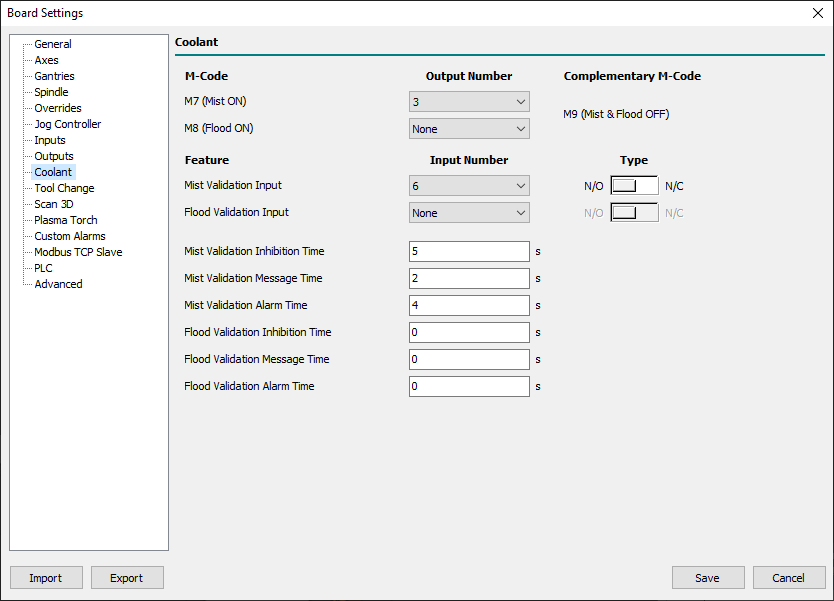

6.9 Coolant

- M7 (Mist ON)

- Defines the number of the user output to use for Mist coolant.

- The Mist coolant output state is controlled in a G-Code program/Macro/MDI using the

M07/M09commands. - If in the menu

Settings→Program Settings→Top Toolbarthe fieldsMist VisibleandMist Enabledare checked when the CNC Board is inIDLEstate the output state can be changed also using related Top Toolbar buttons. - The actual state of Mist coolant is available in G-Code program/Macro/MDI in the parameter

#5153(M7, M9).

- M8 (Flood ON)

- Defines the number of the user output to use for Flood coolant.

- The Flood coolant output state is controlled in a G-Code program/Macro/MDI using the

M08/M09commands. - If in the menu

Settings→Program Settings→Top Toolbarthe fieldsFlood VisibleandFlood Enabledare checked when the CNC Board is inIDLEstate the output state can be changed also using related Top Toolbar buttons. - The actual state of Flood coolant is available in G-Code program/Macro/MDI in the parameter

#5154(M8, M9).

The CNC Board implements also two feedback inputs to control the Pressure/Flow switches signals from Mist & Flood Cooling Systems.

These inputs are optional and when correctly programmed become active during a M07/M08 command or related features in Top Toolbar.

The feedback control operates on M07/M08/M09 commands also if they don't have an assigned user output.

- Mist Input

- Defines the number and logic type of the user input used for the feedback of the Flood Cooling System.

- Flood Input

- Defines the number and logic type of the user input used for the feedback of the Flood Cooling System.

- Mist Inhibition Time

- When the command

M07is executed this is the time in which the Mist feedback signal is inhibited to permit the Mist Cooling System to reach the right pressure.

- Mist Message Time

- When the feedback Mist signal signs a missing Mist pressure to the

Mist Inputstart a watchdog timer. - If the feedback signal is preset continuously for the programmed time a warning message is showed in the Control Software display to warn the end-user of problems in the Mist Cooling System.

- Mist Alarm Time

- When the feedback Mist signal signs a missing Mist pressure to the

Mist Inputstart a watchdog timer. - If the feedback signal is preset continuously for the programmed time the CNC Board enters the

ALARMstate and an error message is showed in the Control Software.

- Flood Inhibition Time

- When the command

M08is executed this is the time in which the Flood feedback signal is inhibited to permit the Flood Cooling System to reach the right pressure.

- Flood Message Time

- When the feedback Mist signal signs a missing Mist pressure to the

Flood Inputstart a watchdog timer. - If the feedback signal is preset continuously for the programmed time a warning message is showed in the Control Software display to warn the end-user of problems in the Flood Cooling System.

- Flood Alarm Time

- When the feedback Flood signal signs a missing Flood pressure to the

Flood Inputstart a watchdog timer. - If the feedback signal is preset continuously for the programmed time the CNC Board enters the

ALARMstate and an error message is showed in the Control Software.

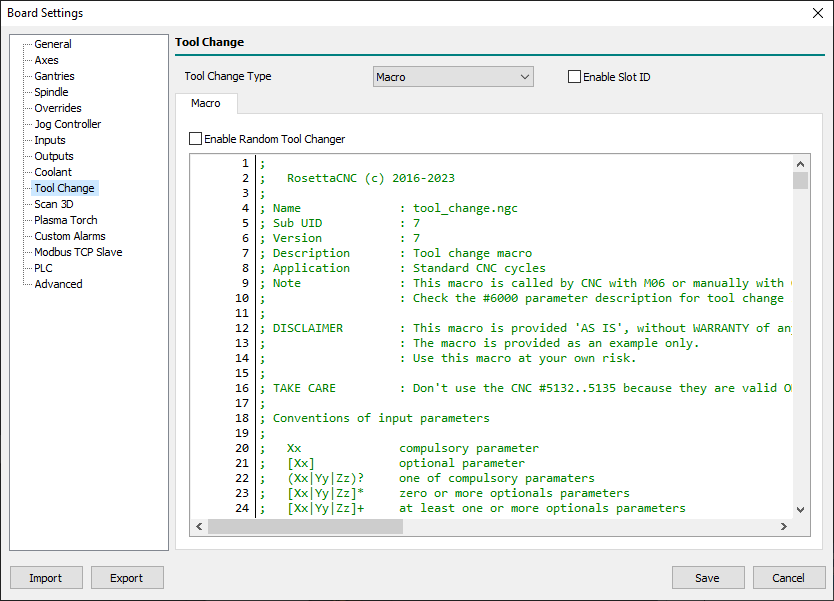

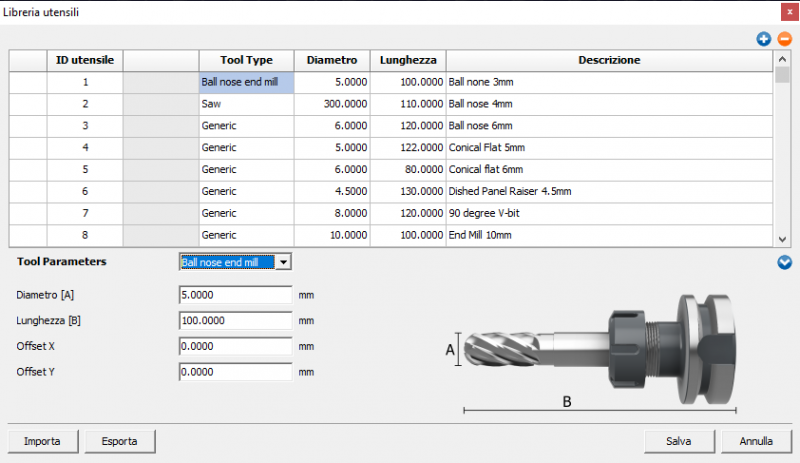

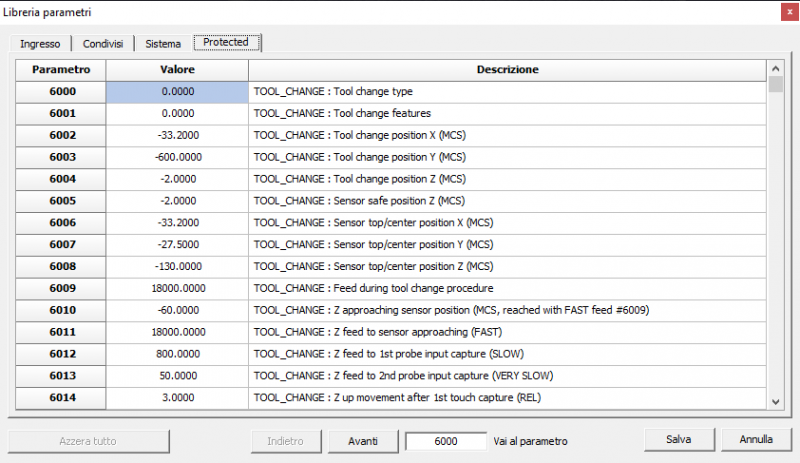

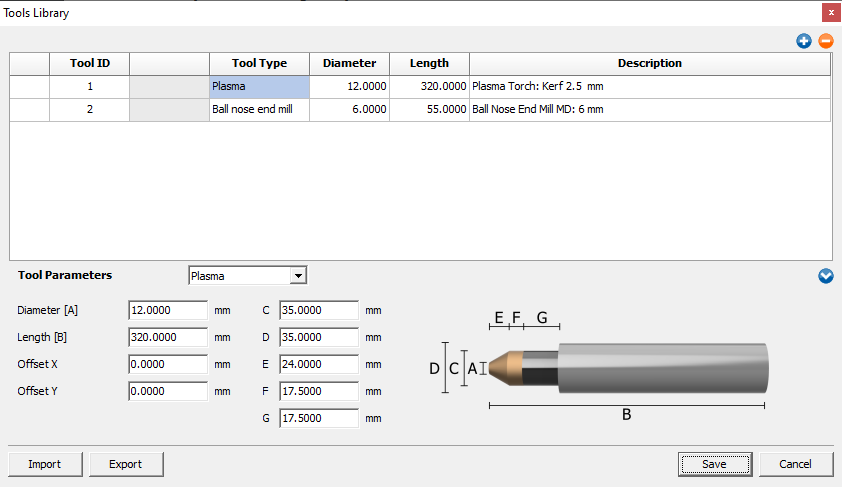

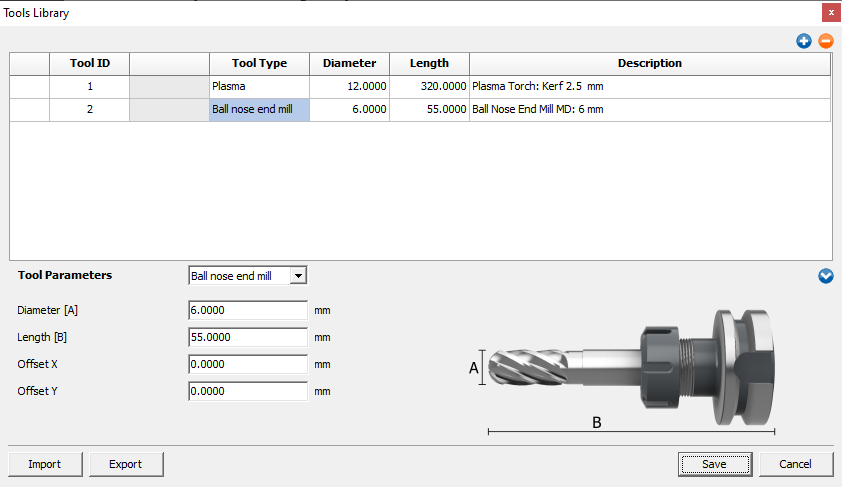

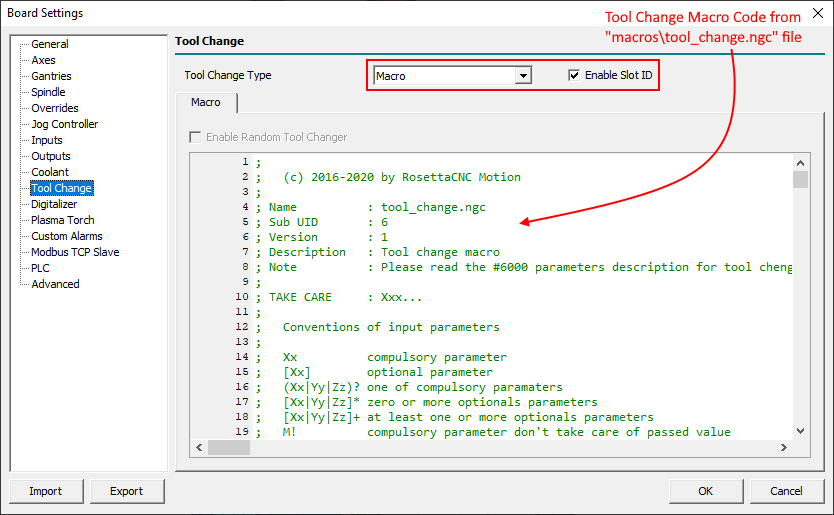

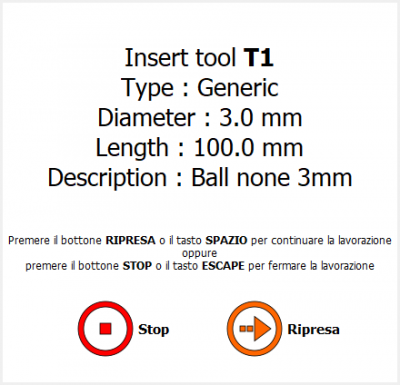

6.10 Tool Change

- In the panel there are 4 fields:

- Tool Change Type

- Defines the way in which the CNC Board manages the

M06command between:- None

- When a

M06command is found by the CNC Board none tool change procedure will be executed and the command will be ignored. - The loaded tool info will be set to

T0, the tool geometry and graphic toolpath color will use the default values. - In this case the H corrector (

G43/G43.1/G43.2/G43.4/G43.7) is correctly managed but requiresH<tool_number>argument to work, otherwise for default will beH0.

- Macro

- When a

M06command is found by the CNC board thetool_change.ngcmacro will be executed. - All actions to get the desired tool change procedure should be placed in that macro.

- The loaded tool info, the tool geometry, and the graphic toolpath color will be set to the tool specified with the

T<tool_number>command. - In this case the H corrector (

G43/G43.1/G43.2/G43.4/G43.7) is correctly managed andH<tool_number>argument is optional.

- PLC

- It is reserved for custom versions of the CNC Board in which the Tool Change management is carried out directly in the CNC instead of the external macro

tool_change.ngc. - Do not use without agreement and support from the CNC Board Support Team.

- Enable Slot ID

- This field is enabled only when the

Tool Change Typeset toMacro/PLC. - The Slot ID feature must be used ONLY if the CNC has an ATC (Automatic Tool Change) System.

- When the field is active it enables the possibility to define the Slot ID in the

Tools Library. - There are two IDs for each tool: Tool ID and Slot ID.

- The Tool ID corresponds to the tool number, therefore Tool ID 1 =

T1, Tool ID 99 =T99. - The Slot ID instead identifies the position of the tool in the tool magazine.

- Tool ID 5 with Slot ID 8 means that tool 5 is in position 8 of the tool magazine, for example, a rack.

- It will then be the task of the macro, suitably written for your machine configuration, to manage the unloading of the tool in use and the withdrawal of the new one from the slot specified during the macro call.

- Macro

- The Macro sheet contains the code of the tool change macro.

- The G-Code editor integrated into the panel allows you to examine and edit the macro contents.

- However, it is possible to examine and modify this macro also through a normal ASCII Text Editor such as NotePad++ by directly accessing the file in the folder:

%APPDATA%\RosettaCNC-1\machines\<your_machine_name>\macros\tool_change.ngc.- To fastly get into the macros folder you can also use the menu

File → Open Macros Folder.

- Enable Random Tool Changer

- The option is currently disabled but foreseen in the CNC Board to manage the case of tool changes where the Slot ID is random and corresponds to the first free and available one.

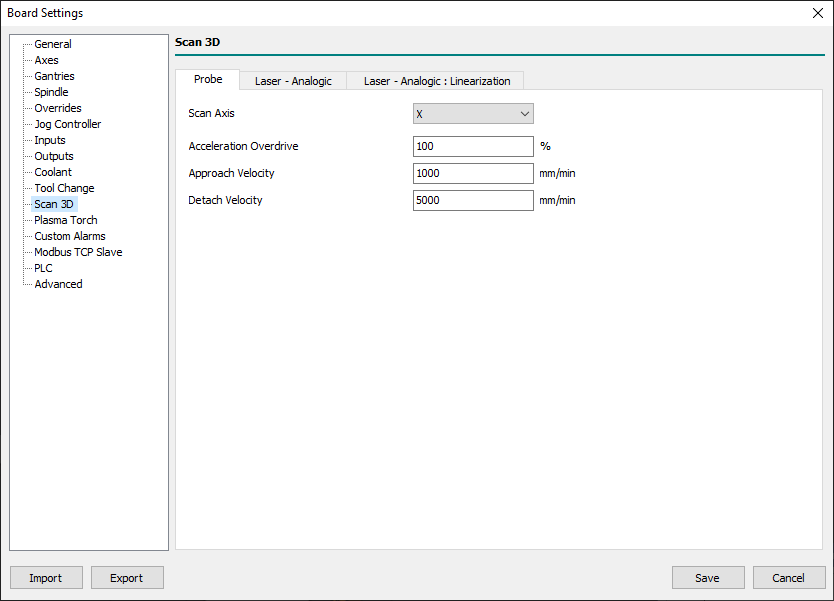

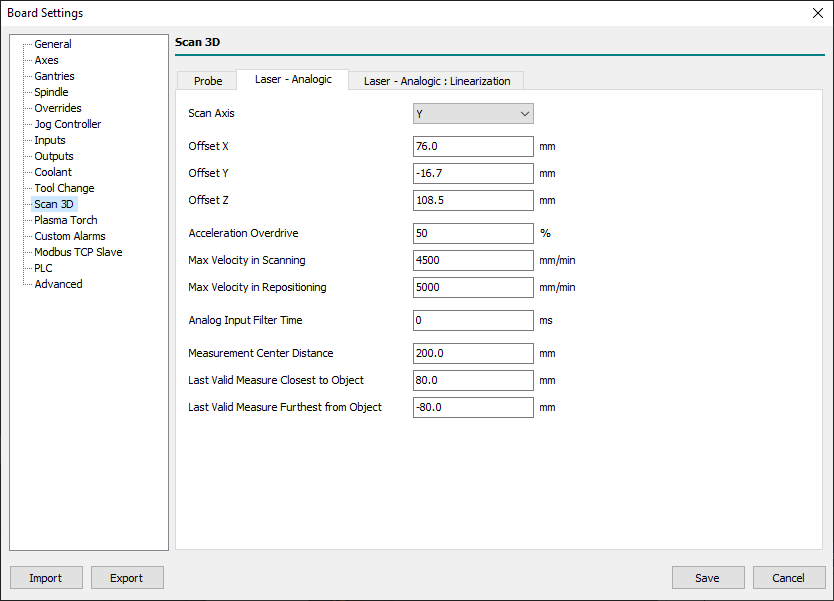

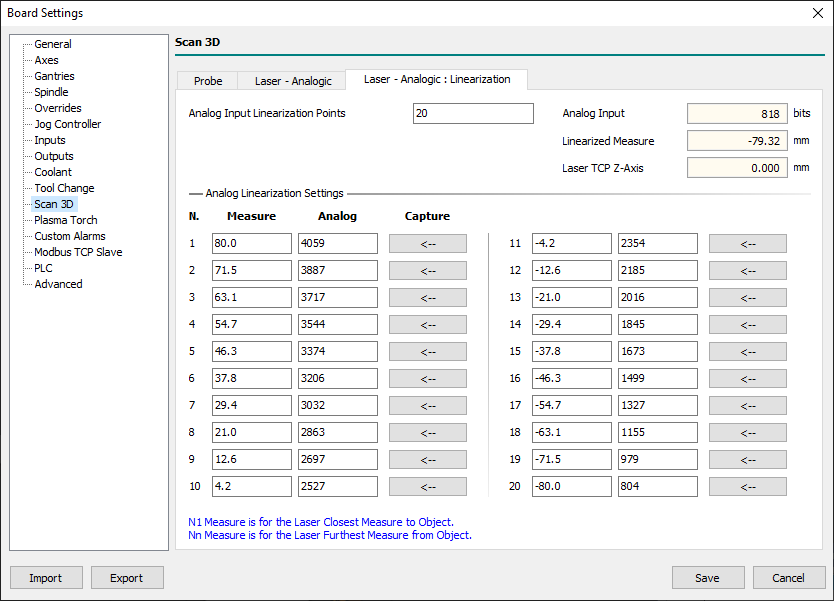

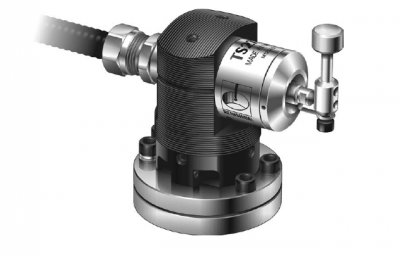

6.11 Scan 3D

6.11.1 Probe

6.11.2 Laser - Analogic

6.11.3 Laser - Analogic : Linearization

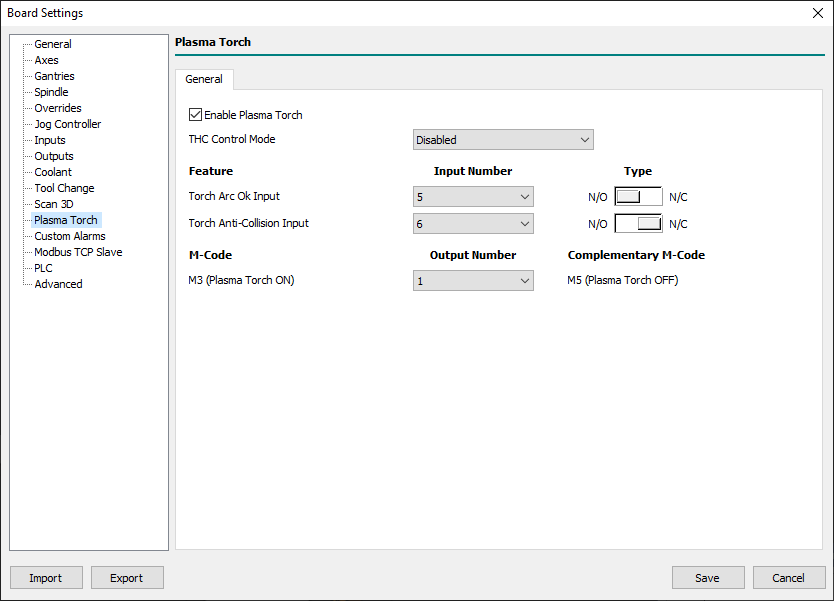

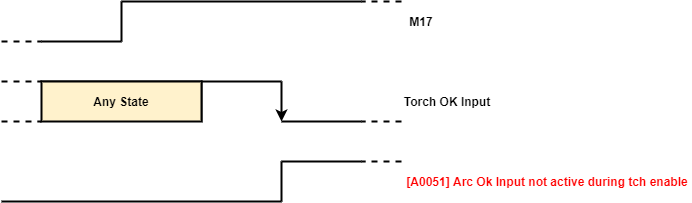

6.12 Plasma Torch

Xxx… (breve descrizione sulle possibilità plasma della CNC).

6.12.1 General

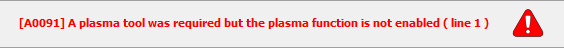

- Enable Plasma Torch

- Enables the CNC Board Plasma Torch management.

- If the plasma torch management is disabled and a

M17orM18command is executed in the G-code, the following alarm will appear:

- THC Control Mode

- Xxx…

- Torch Arc Ok Input

- Defines the user input and the type of logic demanded to receive the ARC OK command signal from the external THC control unit.

- Torch Anti-Collision Input

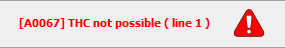

- Defines the user input and the type of logic dedicated to managing the torch collision signal and is optional if the THC control unit don't implement it.

- When the THC is active (

M17) the CNC Board continuously monitors the signal and if it indicates a collision, the machining is immediately stopped and the alarm would appear: - <place image here>

- M3 (Plasma Torch ON)

- Defines the number of user output that sets the plasma torch state.

- This output will be activated on M3 command when a Plasma Tool is enabled otherwise will enable the output set for Spindle clockwise direction.

- If using a Spindle + Plasma Torch system, take care that this output is not the same as clockwise or counterclockwise Spindle activation.

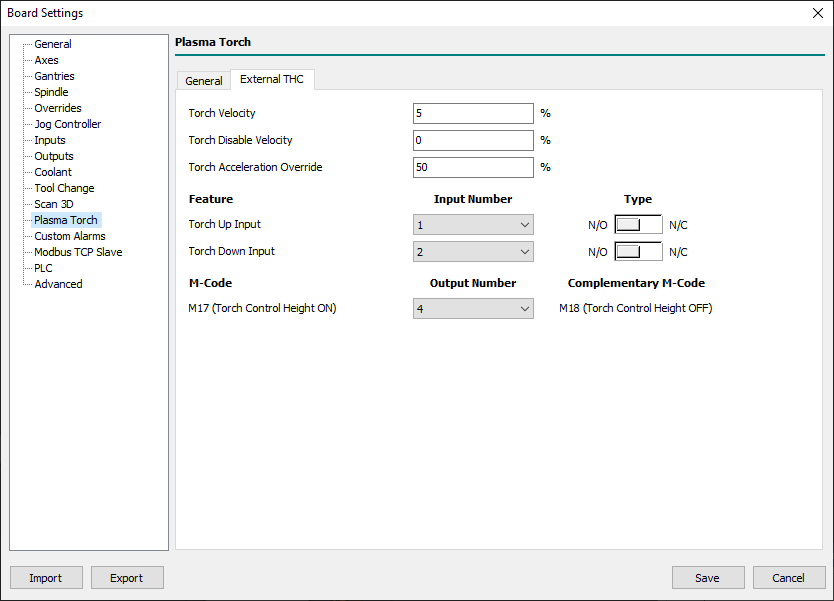

6.12.2 External THC

- Torch Velocity

- Defines the Z-Axis velocity when it is controlled by the THC.

- It is a percentage value of Z-Axis maximum speed.

- Torch Disable Velocity

- Defines a percentage of the feed set in which the THC control is automatically disabled.

- Place zero in this field to disable the function.

- Torch Acceleration Override

- Defines the acceleration of the Z-Axis during the THC check.

- The 100% value means use the full Z-Axis

Acceleration Timeprogrammed value. - The 50% value means use the half Z-Axis

Acceleration Timeprogrammed value.

- Torch Up Input

- Defines the user input and the type of logic demanded to receive the UP command signal from the external THC control unit.

- When THC is enabled (

M17) the Z-Axis movements are demanded to THC which ask, in this way, to CNC Board to move UP the Z-Axis.

- Torch Down Input

- Defines the user input and the type of logic demanded to receive the DOWN command signal from the external THC control unit.

- When the THC is active (

M17) the Z-Axis movements are demanded to THC which ask, in this way, to CNC Board to move DOWN the Z-Axis.

- M17 (Torch Control Height ON)

- Defines the number of user output that is activated when Z-Axis is controlled by the THC device.

- This field is not mandatory.

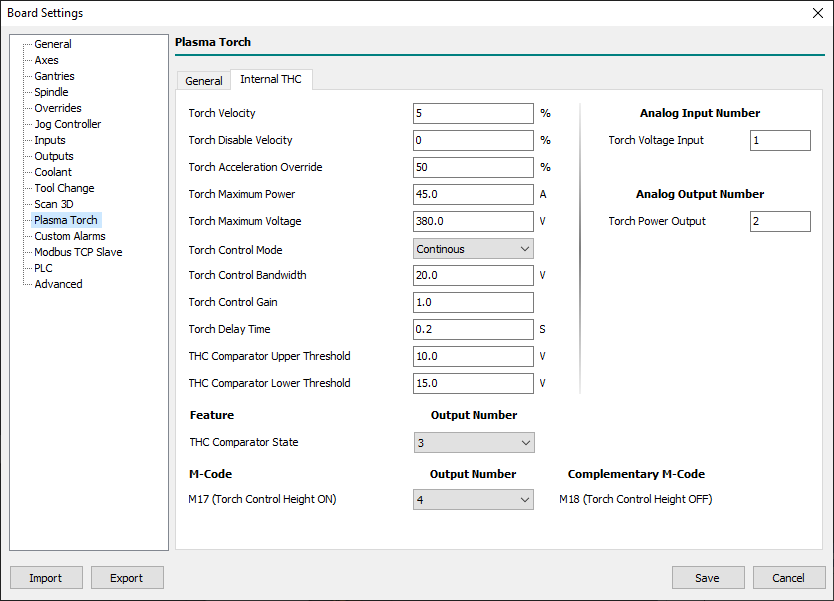

6.12.3 Internal THC

- Torch Velocity

- Xxx…

- Torch Disable Velocity

- Xxx…

- Torch Acceleration Override

- Xxx…

- Torch Maximum Power

- Xxx…

- Torch Maximum Voltage

- Xxx…

- Torch Control Mode

- Xxx…

- Torch Control Bandwidth

- Xxx…

- Torch Control Gain

- Xxx…

- Torch Delay Time

- Xxx…

- THC Comparator Upper Threshold

- Xxx…

- THC Comparator Lower Threshold

- Xxx…

- THC Comparator State

- Xxx…

- THC Comparator State

- Xxx…

- M17 (Torch Control Height ON)

- Xxx…

- Analog Input Number

- Xxx…

- Analog Output Number

- Xxx…

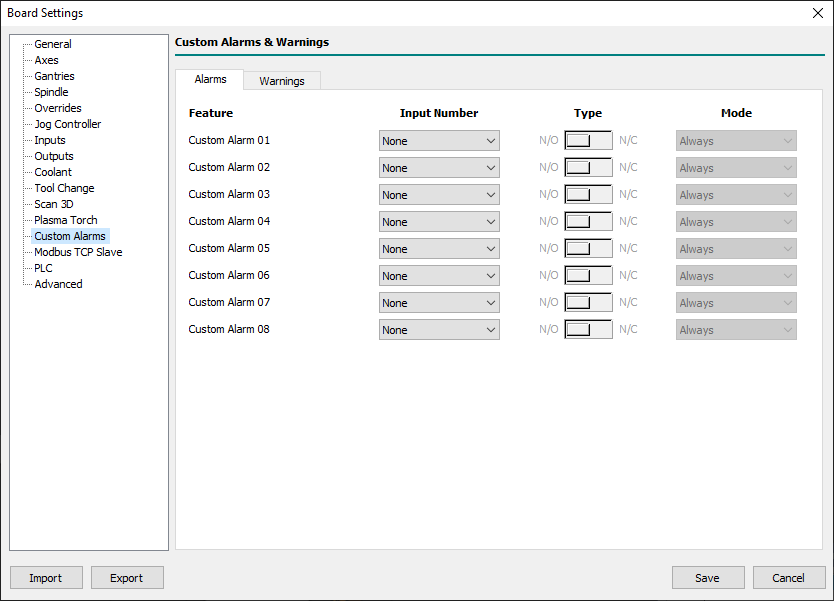

6.13 Custom Alarms

This panel allows you to define Custom Alarms and Warnings associated with a digital User Input.

Each Alarm or Warning can be configured to be issued at a specific level between the Type and Mode fields.

The texts of Alarms and Warnings, displayed when triggered, must be entered in the panel Setup → Program Settings… → Custom Alarms.

6.13.1 Alarms

- Input Number 01..08

- Defines the User Input associated with the custom Alarm 01..08.

- Type

- Defines the type of User Input between:

- NO

- NO = Normally Open.

- This is the normal state of User Input where the Alarm is not raised.

- When the User Input change from the LOW to the HIGH state the related Alarm will be raised.

- NC

- NC = Normally Closed.

- This is the normal state of User Input where the Alarm is not raised.

- When the User Input change from the HIGHT to LOW state the related Alarm will be raised.

- Mode

- Defines when the Alarm check is enabled between:

- Always

- The Custom Alarm check is always enabled.

- RUN

- The Custom Alarm check is enabled only when the CNC Board is in the

RUNstate.

- CHANGE TOOL

- The Custom Alarm check is enabled only when the CNC Board is in the

CHANGE TOOLstate.

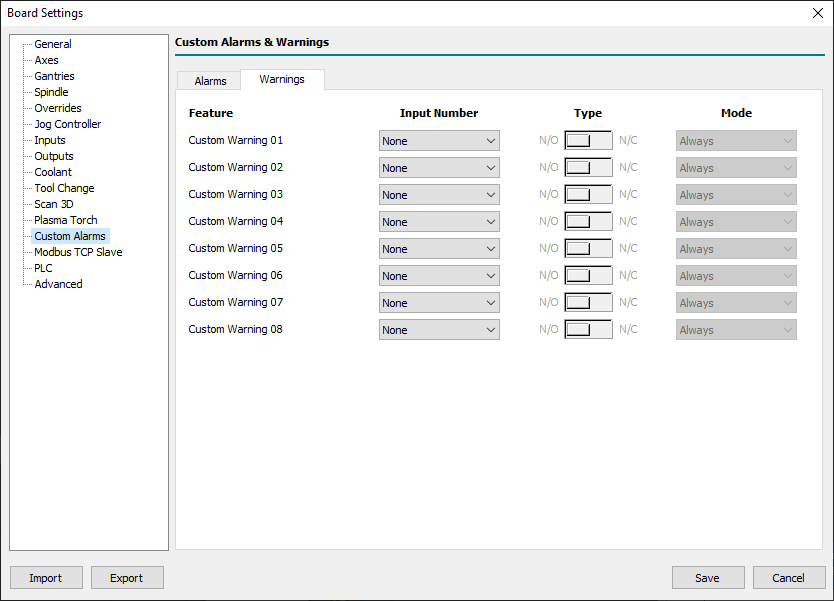

6.13.2 Warnings

- Input Number 01..08

- Defines the User Input associated with the Custom Warning 01..08.

- Type

- Defines the type of User Input between:

- NO

- NO = Normally Open.

- This is the normal state of User Input where the Warning is not raised.

- When the User Input change from the LOW to the HIGH state the related Warning will be raised.

- NC

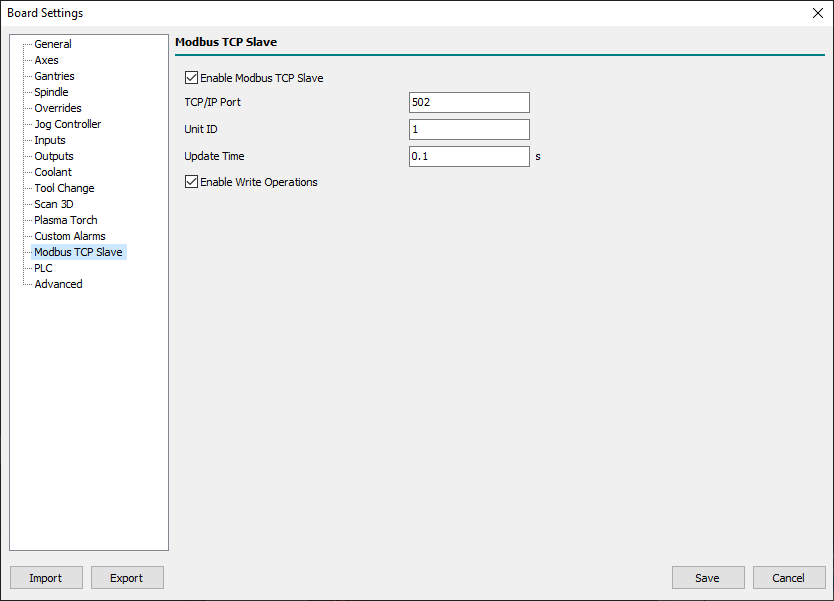

- NC = Normally Closed.